Sizing-free environment-friendly elastic fabric and production process thereof

A technology of elastic fabrics and fabrics, applied in textiles, yarns, fabrics, etc., can solve the problems of large environmental pollution, large amounts of waste water, energy and water consumption, etc., and achieve good skin-friendliness, good environmental protection, and low production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

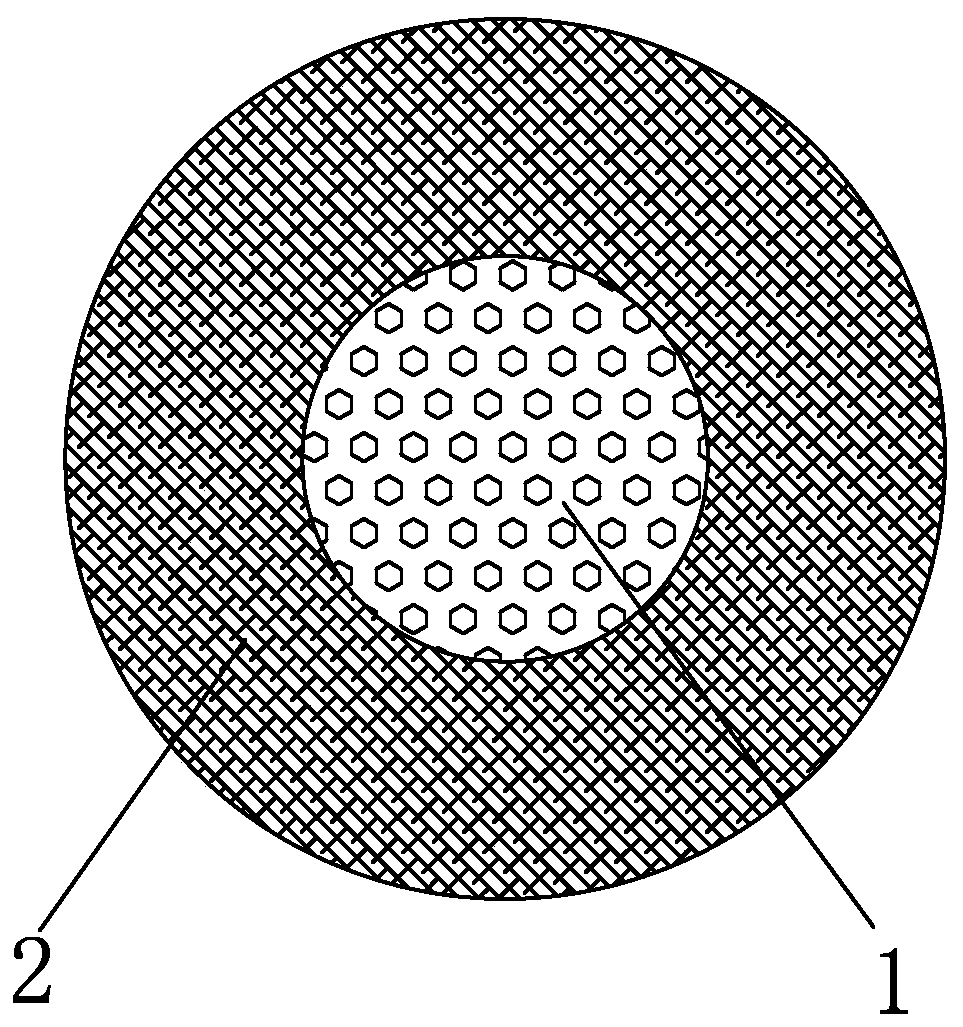

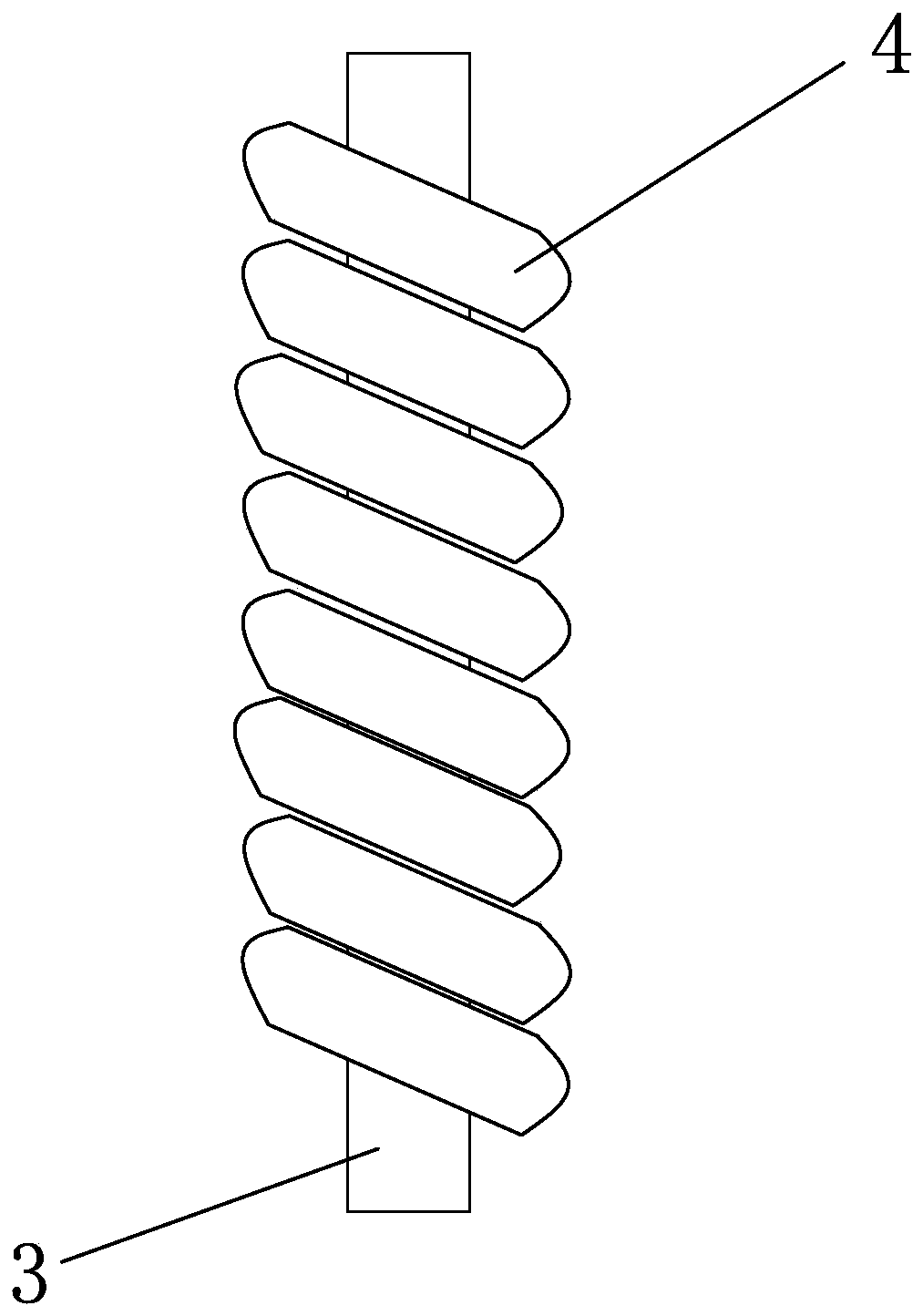

[0023] combine figure 1 and figure 2 , the invention discloses a sizing-free environmentally friendly elastic fabric, comprising a fabric body. The fabric body is a woven fabric woven from warp yarns and weft yarns; the warp yarn of the fabric body is sizing-free cotton yarn. The weft yarn of the fabric body is elastic composite yarn. Sizing-free cotton yarn is made by twisting and plying two strands of sizing-free single yarn. The non-sizing single yarn is a core-spun yarn. The sizing-free yarn uses the carbon fiber filament 1 as the core filament, and the combed cotton fiber 2 as the wrapping fiber, and the combed cotton fiber 2 is spirally wrapped around the carbon fiber filament 1 . The elastic composite yarn includes spandex yarn 3 and bamboo pulp fiber vortex spinning 4 . Bamboo pulp fiber vortex spinning 4 is spirally wound outside the spandex yarn 3 . The warp density and weft density of the fabric body are both less than 600 threads / 10cm.

[0024] In order to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com