Heddle separation detection system and method based on self-learning mode

A detection method and detection system technology, which can be used in optical testing of flaws/defects, material analysis by optical means, measurement devices, etc. Improve the accuracy of classification and detection, improve the efficiency of classification and detection, and reduce the effect of machine errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

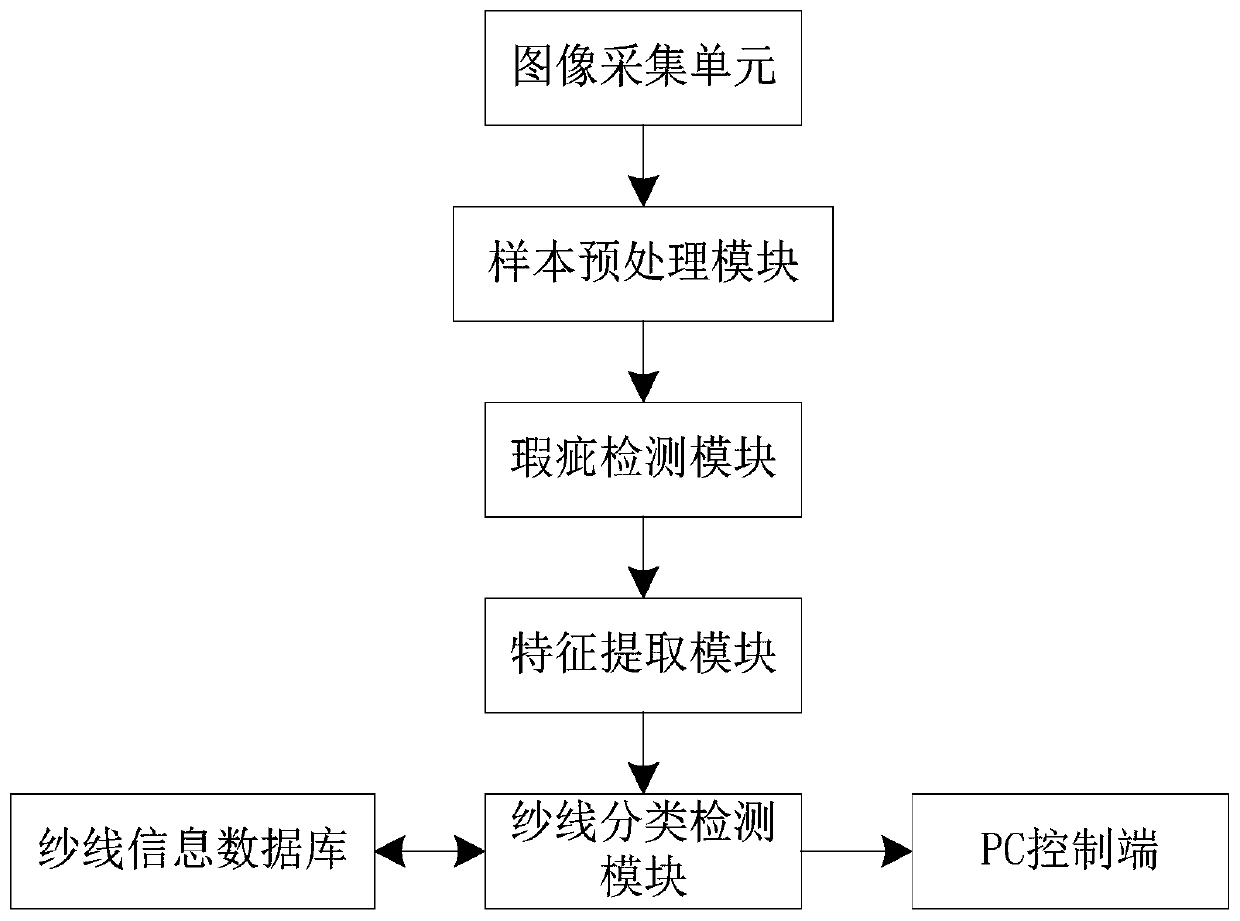

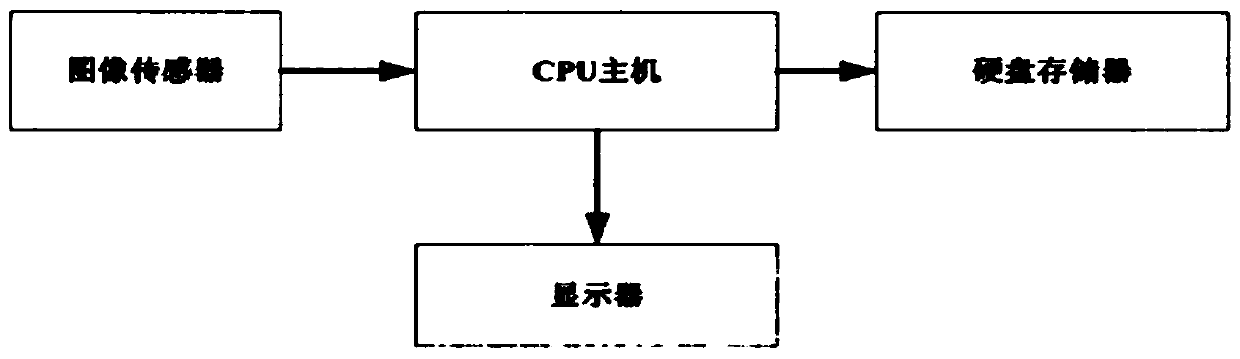

[0042] This embodiment provides a heald separation detection system based on the self-learning mode, such as Figure 1 to Figure 2 Shown:

[0043] It includes an image acquisition unit for sample image acquisition of the yarn to be tested, a sample preprocessing module for preprocessing the sample image, a defect detection module for detecting defect areas on the preprocessed image, and a defect detection module for the preprocessed image The feature extraction module for feature vector extraction of the detected defect area image is used to store the yarn information database of each standard yarn information, and is used to classify and single / multiple yarns to be tested according to the feature vector and each standard yarn information The yarn classification detection module for yarn judgment, and the PC control terminal for corresponding heald separation control according to the yarn classification results to be tested and the single / multi-yarn judgment results. The yarn...

Embodiment 2

[0045] The heald separation detection method based on the self-learning mode comprises the following steps:

[0046] S1. Hook the yarn to be tested, and collect the sample image of the yarn to be tested;

[0047] S2. Preprocessing the collected sample image;

[0048] S3. Perform defect area detection on the preprocessed image, and extract the image of the defect area;

[0049] S4. Extract feature vector information from the defect area image, and at the same time perform classification information extraction on the preprocessed image corresponding to the defect area image;

[0050] S5. According to the characteristic vector information and classification information, classify the yarn to be tested and judge single / multi-yarn, and perform corresponding heddle separation control according to the judgment result.

Embodiment 3

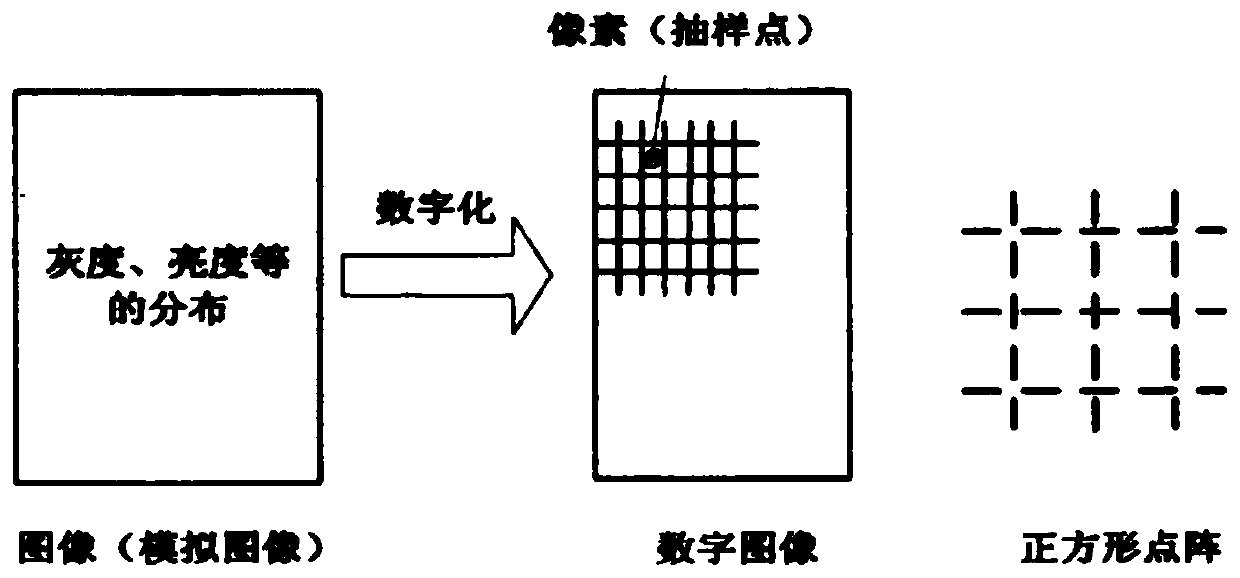

[0052] As an optimization of the above-mentioned embodiment, the process of preprocessing the sample image includes: firstly performing the following steps on the sample image image 3 The image data shown is processed, then image noise reduction processing is performed, and finally image enhancement processing is performed. Such as Figure 4 As shown, mean downsampling is performed on the enhanced image, bilinear interpolation is performed after mean downsampling, and then variance downsampling is performed, and bilinear interpolation is performed after variance downsampling.

[0053] After we obtain the sampled image, the next step is to process it into data, that is, to convert all the information in the image into a form that can be processed by a computer. Specifically, the image is divided into small areas called pixels as shown in the figure below, and the gray value or brightness of each pixel is represented by an integer. In this way, a digital image can be formed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com