Charging and discharging control system and control method thereof

A charge and discharge control and control method technology, applied in battery/fuel cell control devices, charging stations, battery circuit devices, etc., can solve the problems of increasing failure points, increasing costs, and the number of multiple components, and reducing the number of components. Quantity, the effect of reducing control costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

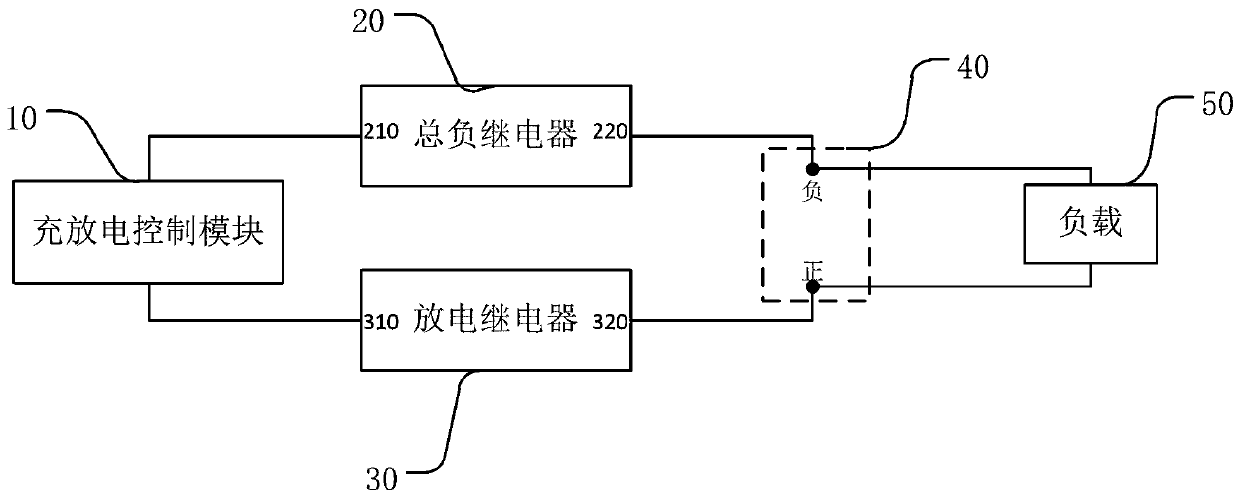

[0032] figure 2 A schematic structural diagram of the charging and discharging control system provided in Embodiment 1 of the present invention, as shown in figure 2 As shown, the charge and discharge control system includes: a charge and discharge control module 10, a total negative relay 20, a discharge relay 30 and a charge and discharge port 40, one end of the charge and discharge control module 10 is connected to the first end 210 of the total negative relay 20, and the charge and discharge control The other end of the module 20 is connected to the first end 310 of the discharge relay 30, the second end 220 of the total negative relay 20 is connected to the negative pole of the charge and discharge port 40, the second end 320 of the discharge relay 30 is connected to the positive pole of the charge and discharge port 40, and the charge and discharge The control module 10 is used to control the on-off state of the total negative relay 20 and the discharge relay 30 accord...

Embodiment 2

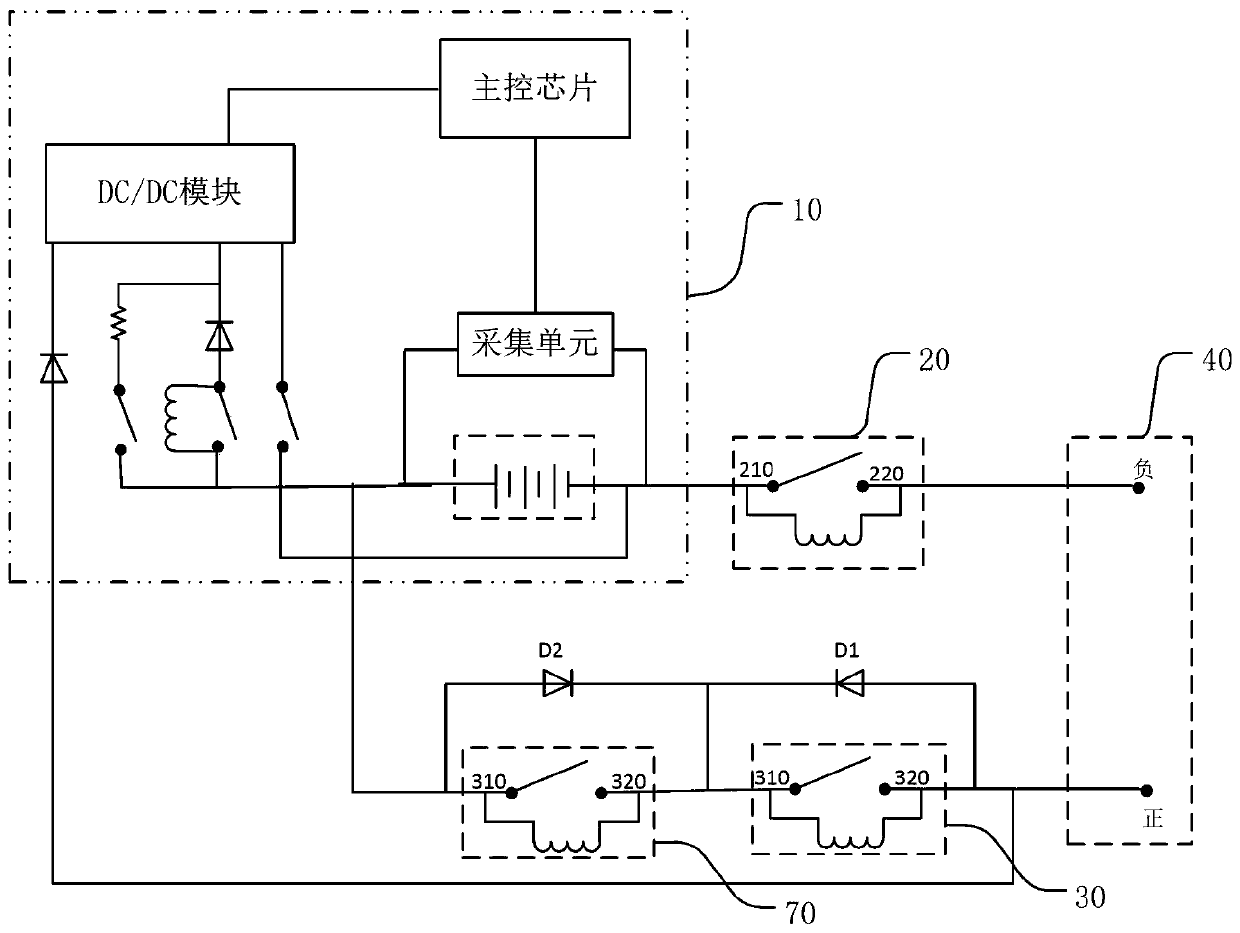

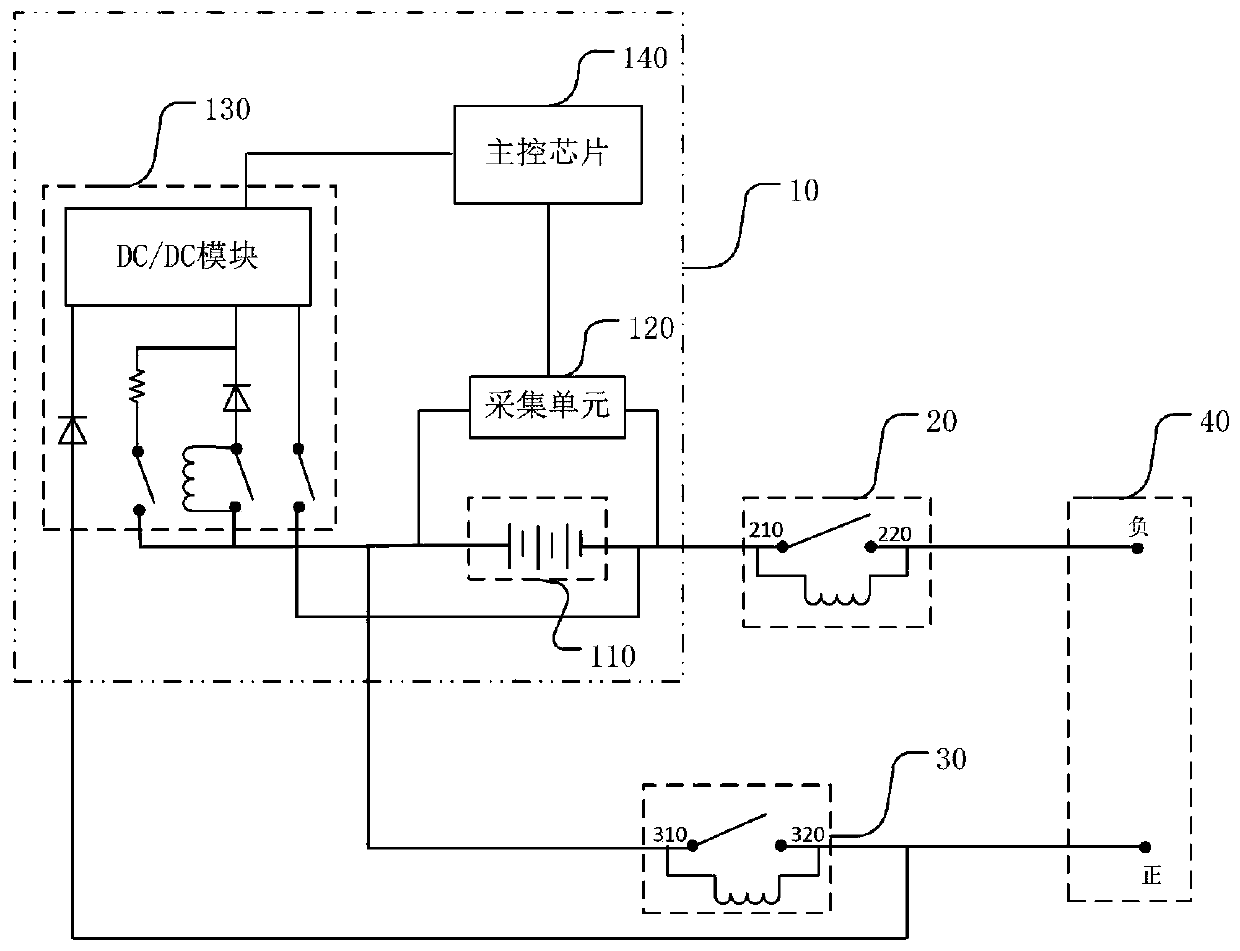

[0044] image 3 A schematic structural diagram of the charging and discharging control system provided in Embodiment 2 of the present invention, as shown in image 3 As shown, the charge and discharge control module 10 includes a battery assembly 110, an acquisition unit 120, a voltage conversion unit 130, and a main control chip 140. The positive pole 111 of the battery assembly 110 is electrically connected to the first end 310 of the discharge relay 30, and the negative pole of the battery pack 110 112 is electrically connected to the first end 210 of the main negative relay 20, and is used for charging and discharging according to the charging rule and the discharging rule.

[0045] Wherein, the positive pole 111 of the battery assembly 110 is electrically connected to the first end 310 of the discharge relay 30, and the negative pole 112 of the battery pack 110 is electrically connected to the first end 210 of the total negative relay 20, and the charge and discharge rela...

Embodiment 3

[0063] Figure 5 The flow chart of the control method of the charging and discharging control system provided by Embodiment 3 of the present invention, as shown in Figure 5 As shown, the control method of the charging and discharging control system includes:

[0064] S100 , in the charging stage, the charging and discharging control module controls the on-off states of the total negative relay and the discharging relay according to the charging rules to perform charging control.

[0065] Optionally, the charging rule includes controlling the discharge relay and the total negative relay to be sequentially closed to turn on the charging path, and then controlling the total negative relay and the discharge relay to be sequentially opened to disconnect the charging path.

[0066] S200 , in the discharge stage, the charge and discharge control module controls the on-off state of the total negative relay and the discharge relay according to the discharge rule to perform discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com