Lithium metal battery

A lithium metal battery and lithium metal technology, applied in lithium batteries, secondary batteries, battery electrodes, etc., can solve problems such as uneven lithium deposition/dissolution, reduced battery cycle performance, safety issues, etc., to improve cycle stability and safety performance, improved lithium deposition/dissolution uniformity, good strength and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] In the preparation method of the lithium metal battery provided by the present invention, the provided protective layer can also include a ceramic material, and the ceramic material can usually be uniformly dispersed in the solution in a suspended manner, so that the protective layer can Disperse evenly.

[0064] Embodiments of the present invention are described below through specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification. The present invention can also be implemented or applied through other different specific implementation modes, and various modifications or changes can be made to the details in this specification based on different viewpoints and applications without departing from the spirit of the present invention.

[0065] It should be noted that the process equipment or devices not specifically indicated in the following examples all ad...

Embodiment 1

[0068] Preparation of positive electrode sheet: the positive active material LiCoO 2 , the conductive agent acetylene black, and the binder PVDF are mixed according to the mass ratio of 96:2:2, and the solvent NMP is added to stir until the system is uniform to obtain the positive electrode slurry; the positive electrode slurry is evenly coated on the aluminum foil of the positive electrode current collector, After drying at room temperature, transfer to an oven to continue drying, and then cut into discs with a diameter of Φ14mm as the positive electrode sheet, and the capacity of the positive electrode surface is 3mAh / cm 2 .

[0069] Negative pole piece preparation:

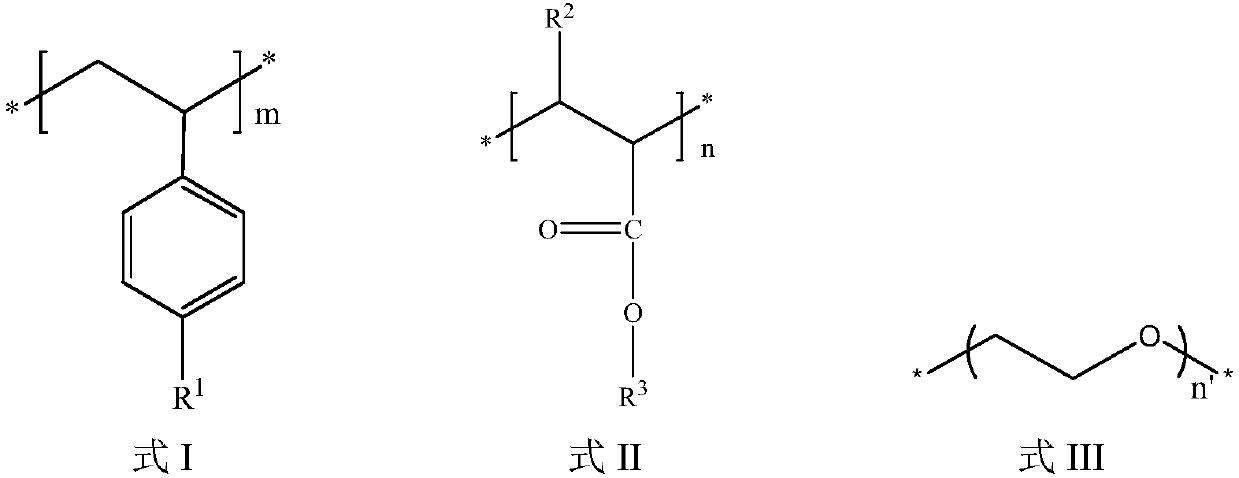

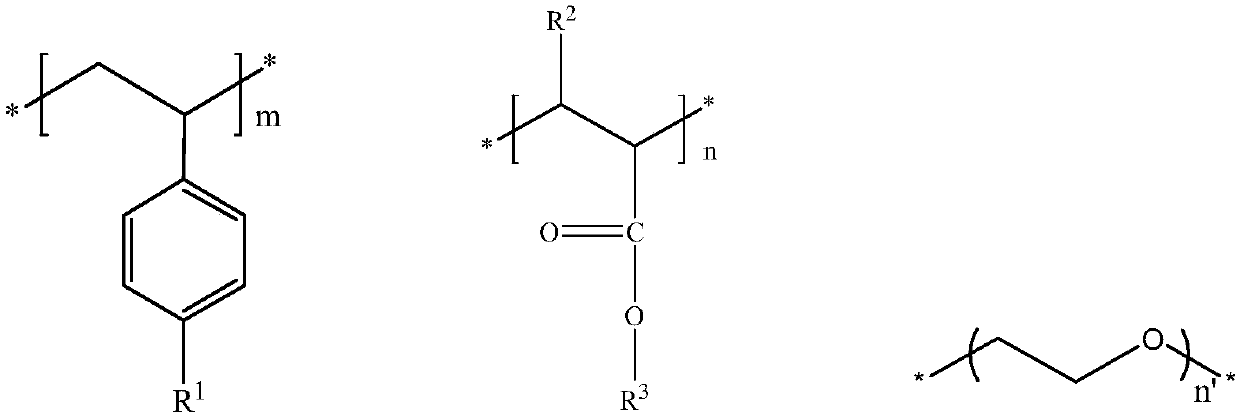

[0070] (1) Preparation of polymer solution: polymer X selects the copolymer of polymer Z and polymer W for use, polymer Z selects styrene for use, and molecular weight is 104g / mol, and polymer W selects polybutylacrylate for use, and molecular weight is 128g / mol mol;

[0071] Polymer Y is made of PVDF with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com