Logo deplating process

A stripping and process technology, applied in metal material coating process, sputtering plating, ion implantation plating and other directions, can solve the problems of increasing energy waste and operation risks, reducing stripping efficiency, and long stripping time, etc. To achieve the effect of automatic operation, good de-plating effect and reduction of operation risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

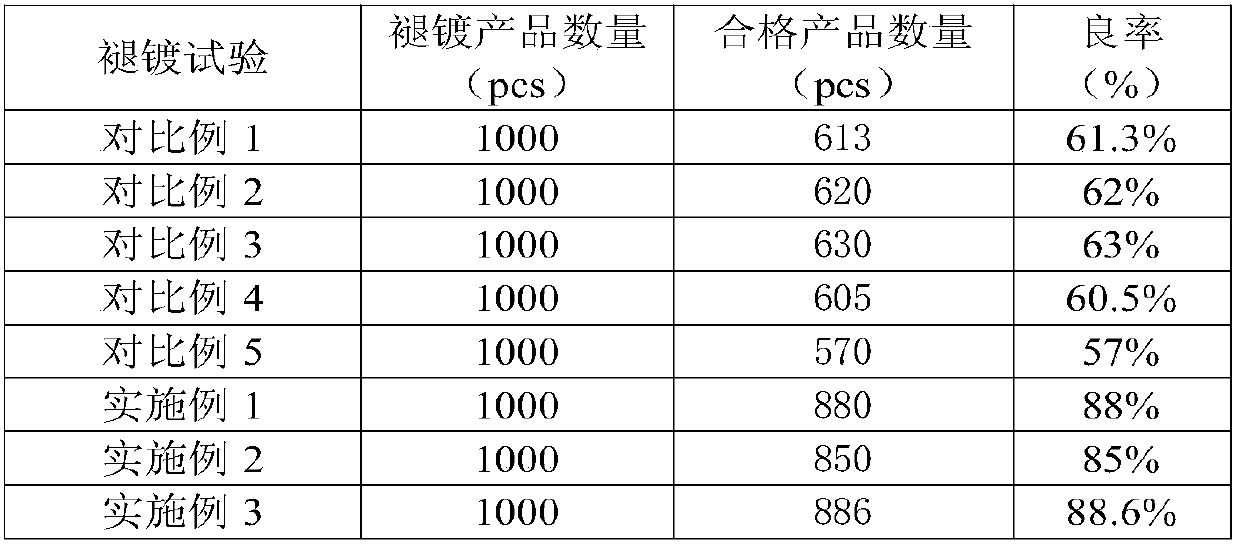

Examples

Embodiment 1

[0037] A logo deplating process, especially suitable for the silver logo deplating of the glass back cover. The equipment used in this method is specifically an ultrasonic cleaning machine. The ultrasonic cleaning machine manufacturer is Shenzhen Hekeda Ultrasonic Equipment Co., Ltd., and the model is HKD- 103240STGF; the PVD film layer used for the silver logo on the glass back cover is aluminum and titanium; the surface oxide of the PVD film layer is aluminum oxide and titanium oxide; the protective ink is provided by Japan Seiko Ink Co., Ltd., and the protective ink is included in mass percentage The following components: xylene accounts for 2.9%, isobutanol accounts for 5%, ethyl acetate accounts for 4.5%, carbon black accounts for 10%, epoxy resin accounts for 76.6%, and the balance additives.

[0038] Include the following steps:

[0039] The first step is to put the product into the deplating solution A and soak it to remove the oxide on the surface of the PVD film;

...

Embodiment 2

[0051] The difference between this embodiment and Example 1 is: when the stripping solution A is stripping the product: the temperature is 15°C, and the stripping time is 30s; when the stripping solution B is stripping the product: the temperature is 15°C. ℃, and the deplating time is 150s; when the deplating solution C deplates the product: the temperature is 70°C, and the deplating time is 300s; the ultrasonic current of the ultrasonic cleaning machine is 2.0 amperes.

Embodiment 3

[0053] The difference between this embodiment and Example 1 is: when the stripping solution A is stripping the product: the temperature is 25°C, and the stripping time is 60s; when the stripping solution B is stripping the product: the temperature is 25°C. °C, the deplating time is 180s; when the deplating solution C is deplating the product: the temperature is 90°C, and the deplating time is 360s; the ultrasonic current of the ultrasonic cleaning machine is 4.0 amperes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com