Nickel removing liquid agent for electronickelling anti-corrosion layer, preparation method and chemical nickel removing process

An anti-corrosion layer and nickel electroplating technology, applied in the field of chemical nickel stripping solution, can solve the problems of long time, complex stripping process and high use temperature, and achieve the effects of less erosion, short nickel stripping time and fast nickel stripping speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

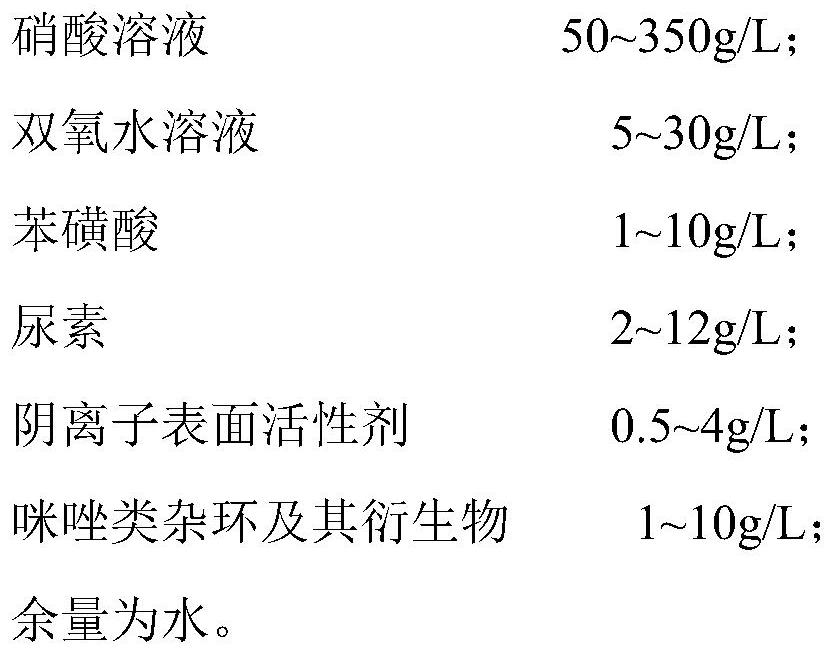

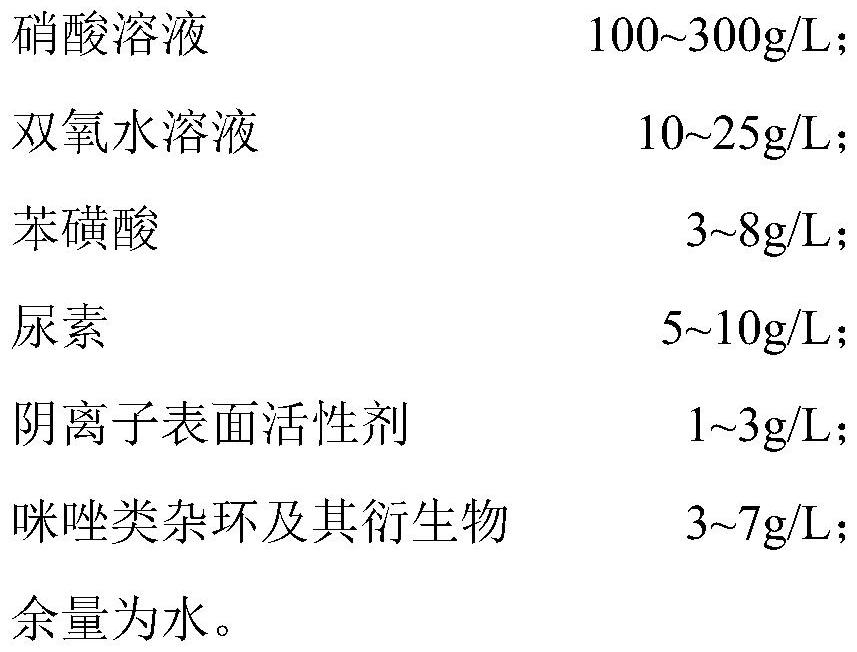

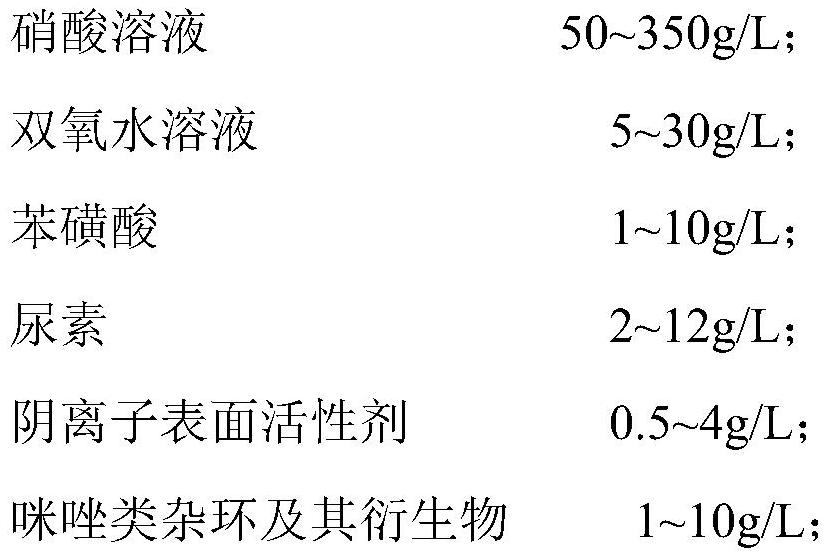

Method used

Image

Examples

Embodiment 1

[0045] The equipment uses a polypropylene container, and the preparation of the nickel-removing potion at room temperature includes the following steps:

[0046] Step 1: In 400-500ml of deionized water, add 50g of nitric acid solution with a mass concentration of 65% per liter of nickel-removing potion, and stir evenly;

[0047] 2. Add 30g of hydrogen peroxide with a mass concentration of 35% per liter of nickel-removing potion, and stir evenly;

[0048] 3. Add 1g of benzenesulfonic acid per liter of nickel-removing potion, and stir until completely dissolved;

[0049] 4. Add 2 g of urea per liter of nickel-removing potion, and stir until completely dissolved;

[0050] 5. Add 1g of imidazole per liter of nickel-removing potion, and stir until completely dissolved;

[0051] 6. Add 4g of sodium lauryl sulfate per liter of nickel-removing potion, and stir until completely dissolved;

[0052] 7. Add the remaining amount of deionized water and stir evenly to obtain the nickel-re...

Embodiment 2

[0054] The equipment uses a container made of polyvinyl chloride, and the preparation of the nickel-removing potion at room temperature specifically includes the following steps:

[0055] Step 1: In 400-500ml of deionized water, add 150g of nitric acid solution with a mass concentration of 65% per liter of nickel-removing potion, and stir evenly;

[0056] 2. Add 15g of hydrogen peroxide with a mass concentration of 35% per liter of nickel-removing potion, and stir evenly;

[0057] 3. Add 3g of benzenesulfonic acid per liter of nickel-removing potion, and stir until completely dissolved;

[0058] 4. Add 12g of urea per liter of nickel-removing potion, and stir until completely dissolved;

[0059] 5. Add 5g of imidazole per liter of nickel-removing potion, and stir until completely dissolved;

[0060] 6. Add 0.5g of sodium lauryl sulfate per liter of nickel-removing potion, and stir until completely dissolved;

[0061] 7. Add the remaining amount of deionized water and stir e...

Embodiment 3

[0063] The equipment is made of Teflon container, and the preparation of the nickel-removing potion at room temperature includes the following steps:

[0064] Step 1. Add 250 g of nitric acid solution with a mass concentration of 65% per liter of nickel-removing potion in 400-500 ml of deionized water, and stir evenly;

[0065] 2. Add 30g of hydrogen peroxide with a mass concentration of 35% per liter of nickel-removing potion, and stir evenly;

[0066] 3. Add 10g of benzenesulfonic acid per liter of nickel-removing potion, and stir until completely dissolved;

[0067] 4. Add 2 g of urea per liter of nickel-removing potion, and stir until completely dissolved;

[0068] 5. Add 10g of imidazole per liter of nickel-removing potion, and stir until completely dissolved;

[0069] 6. Add 2g of sodium lauryl sulfate per liter of nickel-removing potion, and stir until completely dissolved;

[0070] 7. Add the remaining amount of deionized water and stir evenly to obtain the nickel-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com