Iron removing liquid and aluminum alloy surface iron layer removing technology

A technology of iron removal and process, applied in the direction of metal material coating process, etc., can solve the problems of low production efficiency, large waste slag discharge, high energy consumption of sandblasting, etc., and achieve the effect of ensuring health and safety, simple ingredients and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

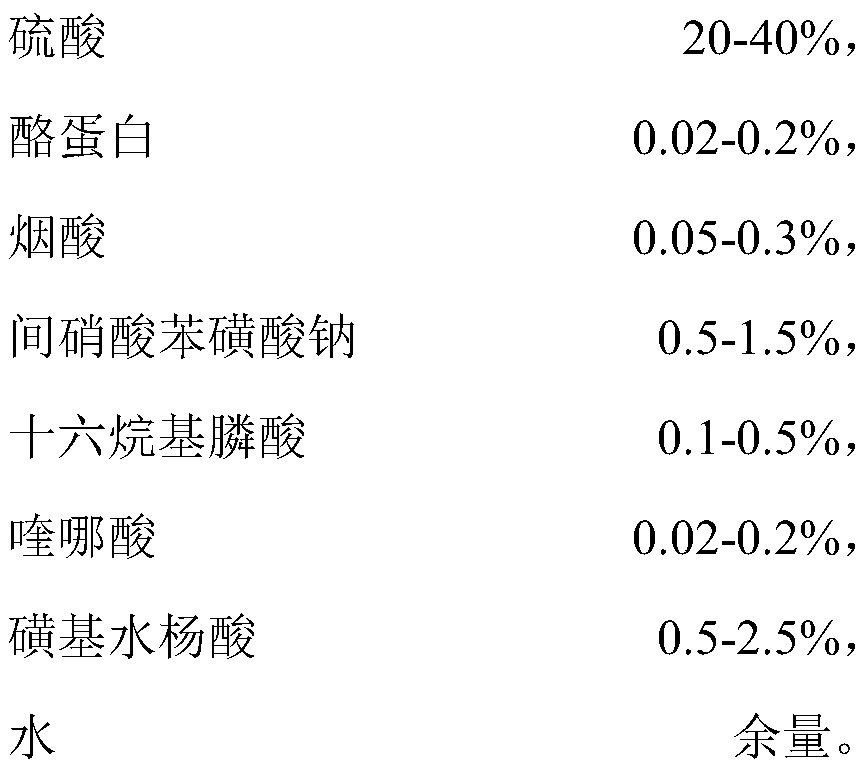

[0044] A kind of iron alamentin, by mass percentage, comprises following component:

[0045]

[0046] A preparation method of iron anaphora solution, comprising the following steps:

[0047] Dissolve casein and nicotinic acid in water at 45°C according to the percentage, stir to dissolve, and obtain solution A;

[0048] Dissolve sodium m-nitrate benzenesulfonate and cetyl phosphonic acid in water according to the percentage, stir to dissolve it, and obtain solution B;

[0049] Dissolving quinalic acid and sulfosalicylic acid in water according to the percentage, stirring to dissolve, and obtaining solution C;

[0050] Slowly add sulfuric acid into the PP tank that has been filled with water according to the percentage. The temperature of the solution in the feeding is controlled within 70 degrees. When the temperature drops to within 65 degrees, add solution B and stir evenly, then add solution C and stir evenly, and finally add The solution A is stirred evenly to obtain ...

Embodiment 2

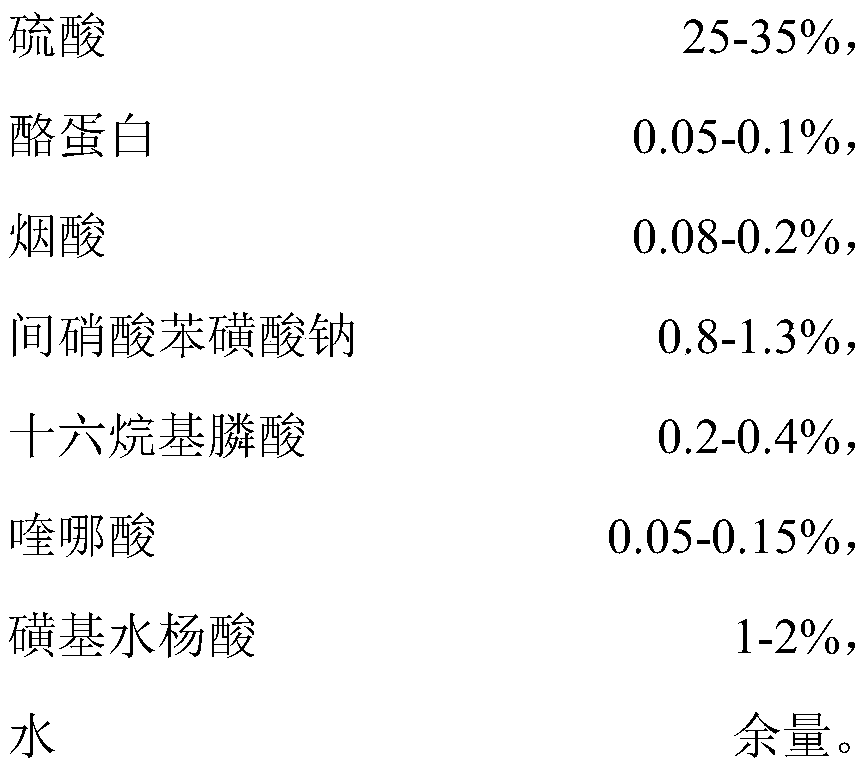

[0054] A kind of iron alamentin, by mass percentage, comprises following component:

[0055]

[0056] The preparation method of the iron anaphora solution of the present embodiment is the same as that in Example 1.

[0057] A process for removing an iron layer on the surface of an aluminum alloy, comprising the following steps:

[0058] The temperature of the iron removal solution is controlled at 60°C. Put the aluminum alloy cookware to be iron removal into the heating device of the iron removal tank equipped with the iron removal solution to start the iron removal. At the beginning, the reaction is more violent and more gas is generated. When the reaction When there is no obvious gas generation when slowing down significantly, take out the aluminum alloy cookware and observe whether the iron layer on the surface is completely removed; if it is completely removed, wash it with clean water at room temperature.

Embodiment 3

[0060] A kind of iron alamentin, by mass percentage, comprises following component:

[0061]

[0062]

[0063] The preparation method of the iron anaphora solution of the present embodiment is the same as that in Example 1.

[0064] A process for removing an iron layer on the surface of an aluminum alloy, comprising the following steps:

[0065] The temperature of the iron-removing solution is controlled at 65°C. Put the aluminum alloy cookware to be iron-removed into the iron-removing tank heating device equipped with the iron-removing solution to start the iron removal. The reaction is more violent at the beginning and more gas is generated. When the reaction When there is no obvious gas generation when slowing down significantly, take out the aluminum alloy cookware and observe whether the iron layer on the surface is completely removed; if it is completely removed, wash it with clean water at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com