Multifunctional water pump

A multi-functional, water pump technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of impeller damage of power pumps, shorten the service life of power pumps, etc., and achieve the effects of low cavitation, reduced cost of accessories, and reduced maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

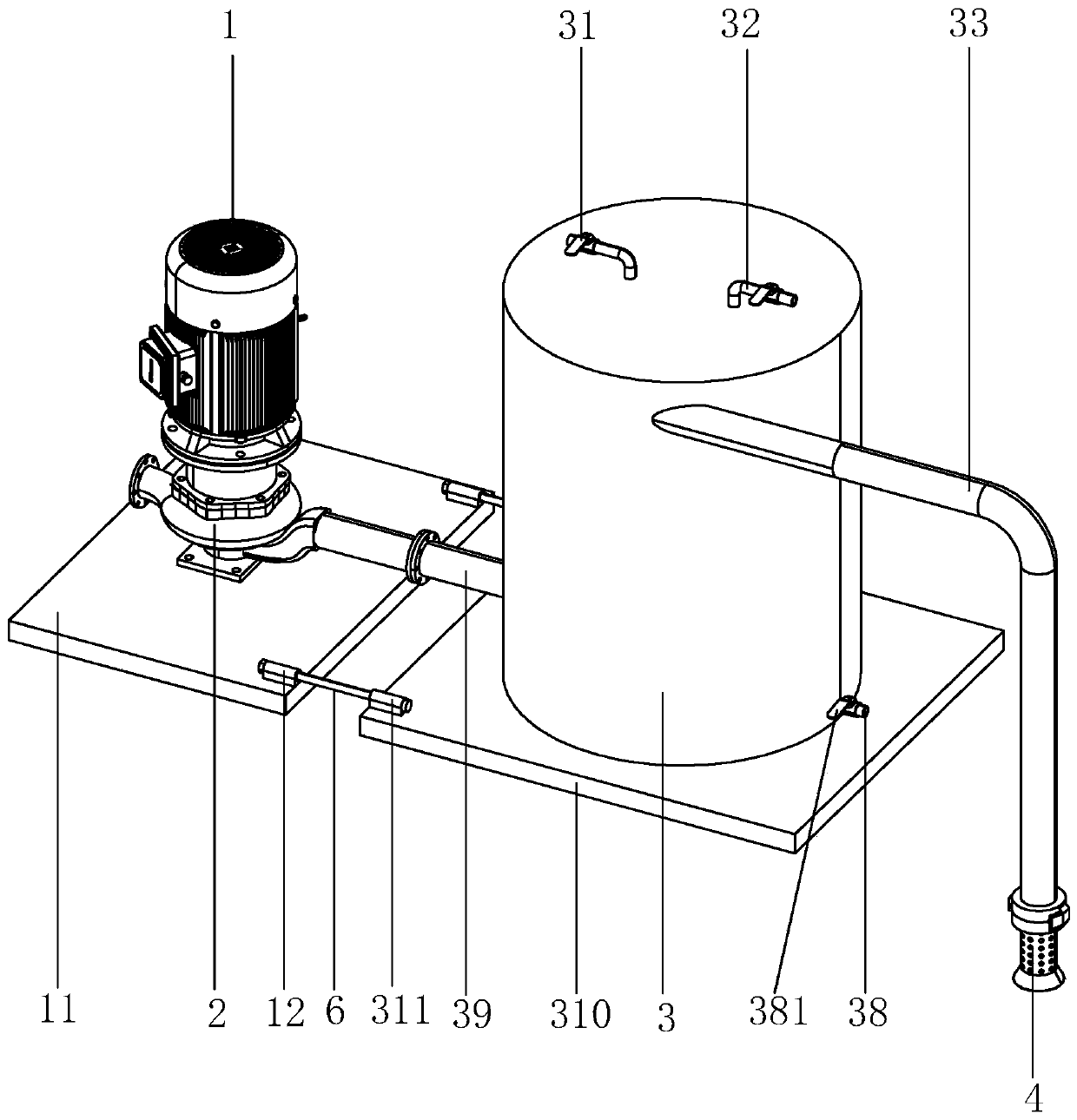

[0053] Embodiment 1: a kind of multifunctional water pump, as figure 1 As shown, it includes a drive motor 1, a pump body 2, and a siphon tank 3.

[0054] Such as figure 1 As shown, the siphon tank 3 is cylindrical. In addition, the siphon tank 3 is not limited to a cylindrical shape, and may also be other columnar structures. The top surface of the siphon tank 3 is provided with an exhaust valve 31 and a water injection pipe 32. Under initial conditions, water is injected into the siphon tank 3 through the water injection pipe 32, and the air in the siphon tank 3 is discharged through the exhaust valve 31, thereby maintaining internal and external air pressure. balance.

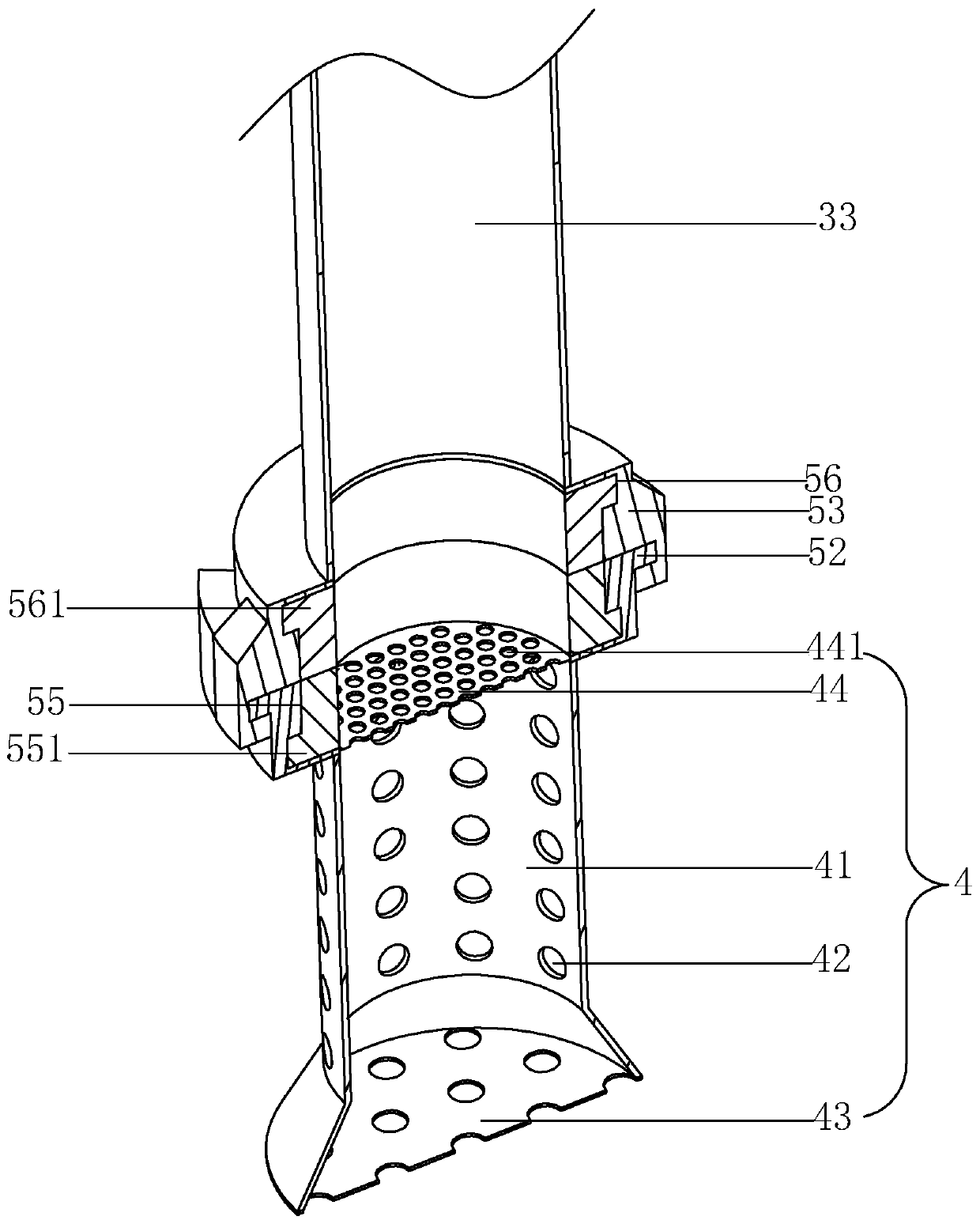

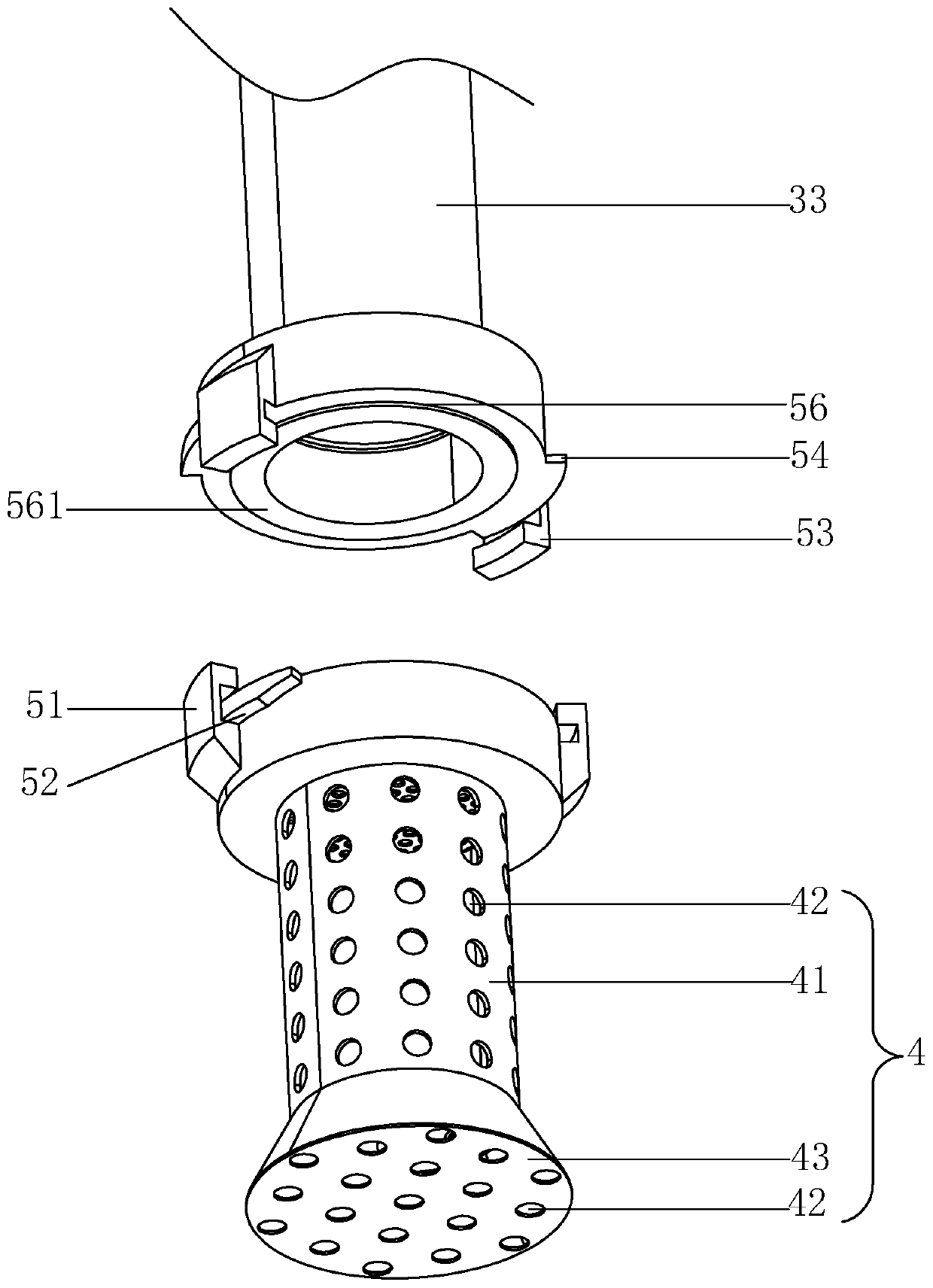

[0055] Siphon tank 3 is provided with water inlet pipe 33 near the position of its top, and water inlet pipe 33 is communicated with siphon tank 3 along the tangential direction of siphon tank 3, and water inlet pipe 33 adopts hard metal material to make. One end of the water inlet pipe 33 facing away fro...

Embodiment 2

[0074] Embodiment 2: a kind of multifunctional water pump, as Figure 10 and 11 As shown, the difference from Implementation 1 is that the bottom wall of the siphon tank 3 is provided with a sewage discharge tank 71, the sewage discharge tank 71 passes through the central axis of the siphon tank 3, and two spiral extruding rods 73 are arranged in the sewage discharge tank 71. Two spiral extruding rods 73 are arranged symmetrically about the axis of siphon tank 3, and sewage discharge pipes 72 are provided on the two side walls of siphon tank 3, and the opposite ends of the two spiral extruding rods 73 extend into corresponding sewage discharge pipes 72 respectively, and the sewage discharge A purge valve 76 is provided on the pipe 72 .

[0075]The opposite ends of the two spiral extruding rods 73 are provided with a first bevel gear 74, and the bottom end of the rotating shaft 34 is provided with a second bevel gear 75, and the second bevel gear 75 meshes with the two first b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com