Anti-crack reinforcement material for long-life concrete products and its preparation method and application

A technology of concrete products and reinforcing materials, which is applied in the field of building materials, can solve the problems of uncoordinated development of product strength, crack resistance and durability, affect the durability and service life of concrete products, and uneven distribution of hydration products, etc., to achieve Significant social benefits and the environment, reducing unilateral water consumption, and increasing the effect of volume stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

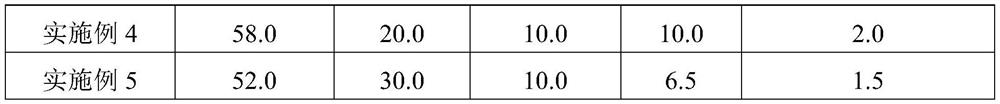

[0038] The preparation method of the anti-crack reinforcing material for long-life concrete products of the above-mentioned embodiments 1-5 comprises the following steps:

[0039] The steel slag, fly ash, calcium carbide slag, gypsum and the stabilized modified material are uniformly mixed in the formulated amount to obtain the anti-crack reinforcing material for the long-life concrete product.

Embodiment 1

[0040]The method of using the anti-cracking reinforcing material for long-life concrete products in Example 1 is as follows: mix the above materials evenly to obtain the anti-cracking reinforcing material for long-life concrete products. The mixing ratio of the benchmark concrete test is powder (cement + anti-crack reinforcing material): fine aggregate: coarse aggregate: water: water reducer = 380:745:1118:152:3.5 (by weight). After adding water and stirring according to the above mixing ratio, prepare a 100mm×100mm×100mm cube specimen and a 100mm×100mm×300mm prism specimen with a longitudinal limiter respectively. Both the cube specimen and the prism specimen were steamed in a 40°C curing box for 6 hours, then taken out and cooled to room temperature (20±2)°C. According to GB / T 50081-2019 "Standards for Test Methods of Mechanical Properties of Ordinary Concrete" and GB 50119-2013 "Technical Specifications for the Application of Concrete Admixtures", the 6h limited expansion r...

Embodiment 2

[0041] The method of using the anti-cracking reinforcing material for long-life concrete products in Example 2 is as follows: mix the above materials evenly to obtain the anti-cracking reinforcing material for long-life concrete products. The mixing ratio of the benchmark concrete test is powder (cement + anti-crack reinforcing material): fine aggregate: coarse aggregate: water: water reducer = 380:745:1118:152:3.5 (by weight). After adding water and stirring according to the above mixing ratio, prepare a 100mm×100mm×100mm cube specimen and a 100mm×100mm×300mm prism specimen with a longitudinal limiter respectively. Both the cube specimen and the prism specimen were steamed in a 40°C curing box for 6 hours, then taken out and cooled to room temperature (20±2)°C. According to GB / T 50081-2019 "Standards for Test Methods of Mechanical Properties of Ordinary Concrete" and GB 50119-2013 "Technical Specifications for the Application of Concrete Admixtures", the 6h limited expansion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com