Technology for KR liquid iron pretreatment desilicication and dephosphorization

A molten iron pretreatment and molten iron technology, which is applied in the field of iron and steel smelting, can solve problems such as deterioration of iron and steel material consumption indicators, splashing, impact on environmental protection production continuity, etc., and achieve considerable economic benefits, reduce iron and steel material consumption, and reduce the effect of silicon content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

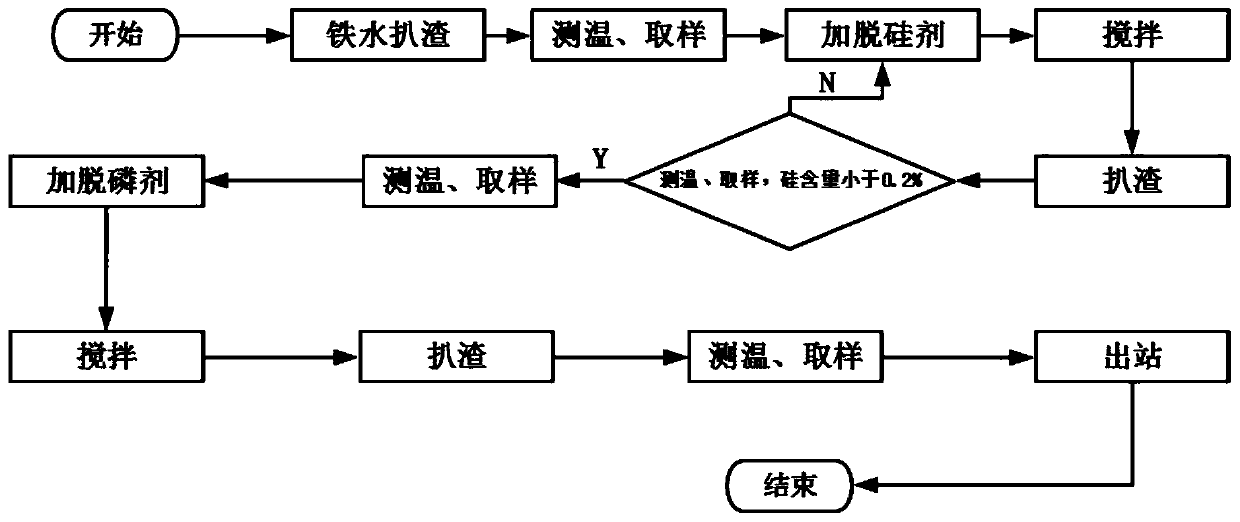

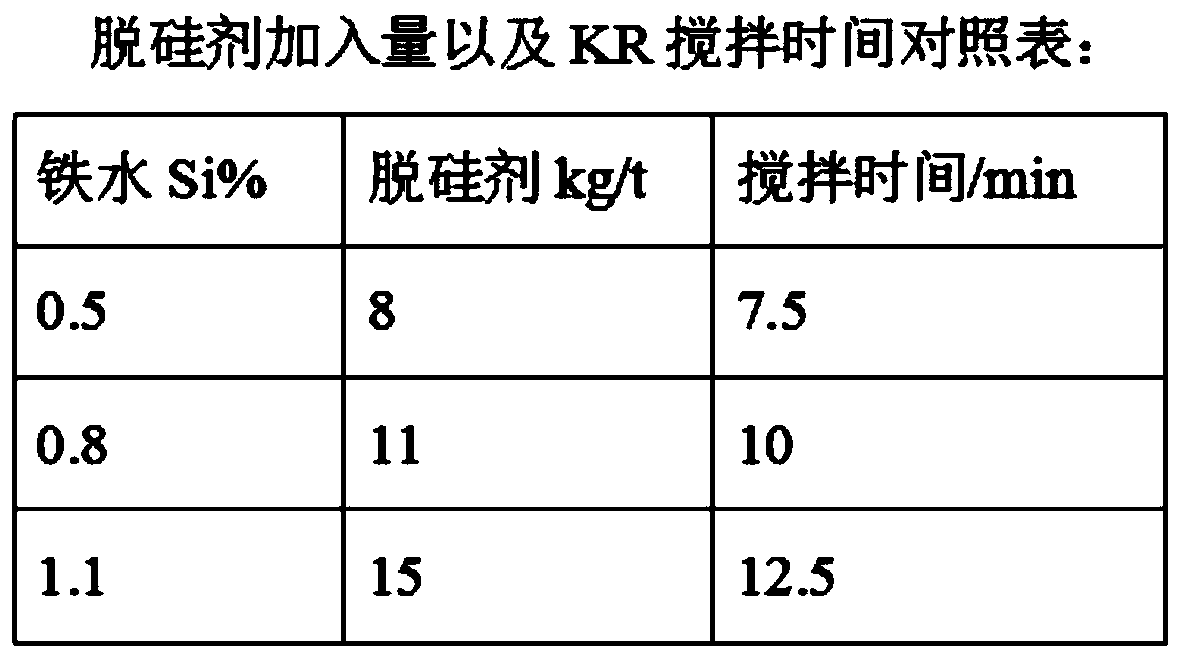

Method used

Image

Examples

Embodiment

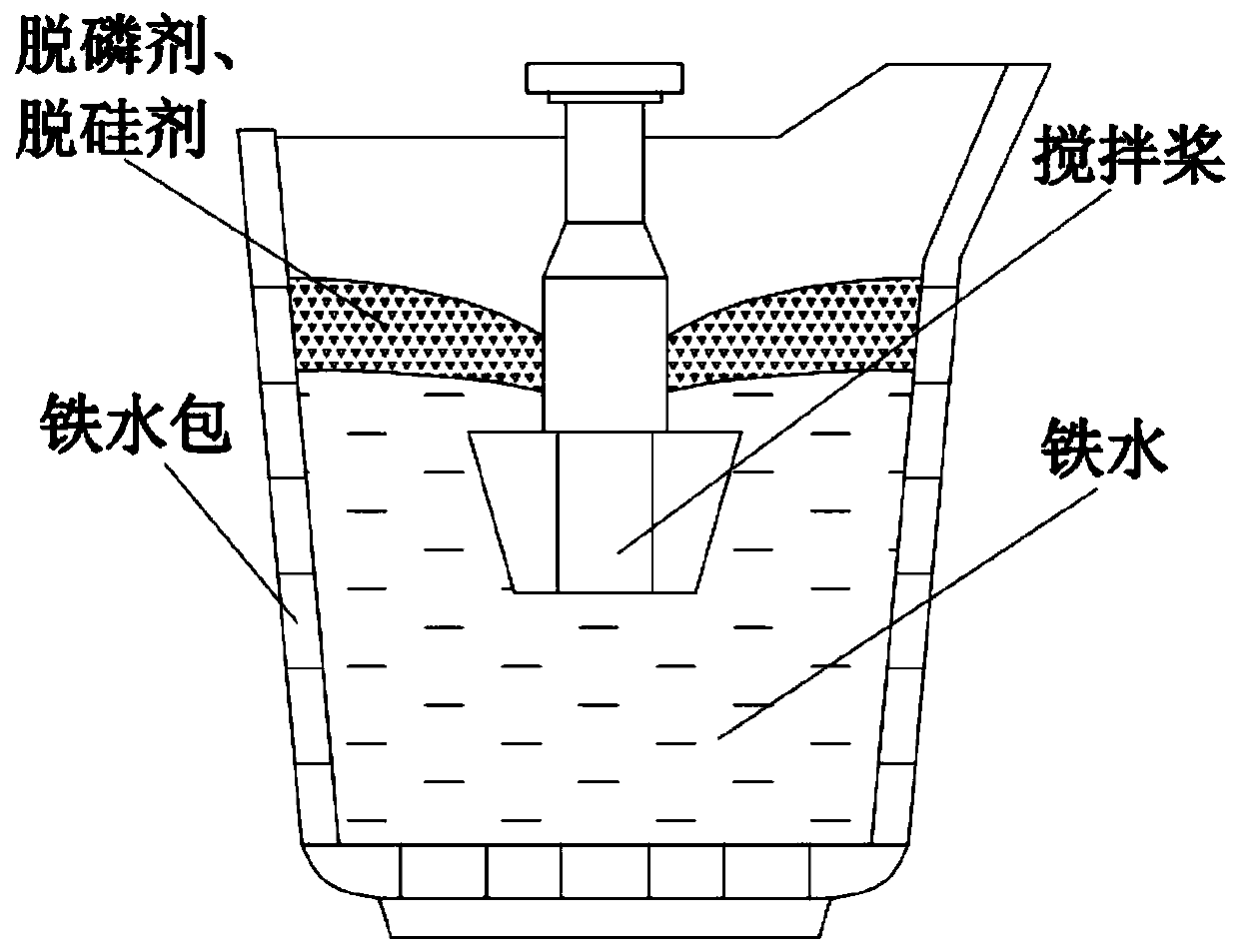

[0055] Example: Drain the molten iron to be desiliconized and dephosphorized into the molten iron ladle. After the molten iron is in place, remove the scum floating on the surface of the molten iron to avoid it, and then measure the temperature at 1311°C. The weight after removing the slag is 153 tons. The net weight is 109t; then artificially add about 700kg of iron oxide scale, then stir with the paddle, the speed gradually increases to 90 rpm, and the insertion depth is 1150mm; the stirring time is 8min; then the slag is removed to measure the temperature at 1288°C, and the sample is taken; then add 900kg of iron oxide scale, 50kg Fluorite, stir with the paddle for 8 minutes, and add 1.2 tons of lime at the same time; after the stirring is completed, the slag is removed and the temperature is measured at 1288°C, the sample is taken, and it is discharged from the station. After the sampling test, the contents of various substances in the molten iron are as Figure 5 shown by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com