Permanent magnet magneto-rheological fan clutch of internal combustion engine and fan

A magnetorheological and internal combustion engine technology, applied in the field of clutch, can solve the problems of small maximum torque value, inability to automatically adjust, poor heat dissipation effect, etc., to achieve the effect of increasing friction torque, avoiding easy failure, and enhancing heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

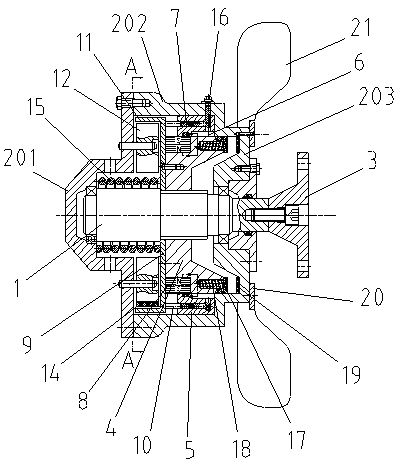

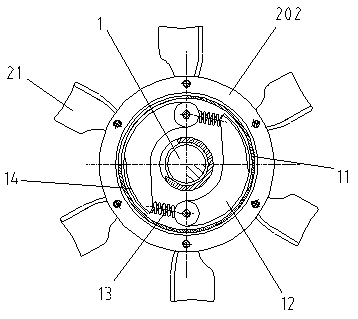

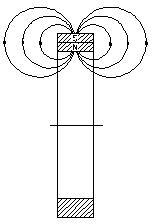

[0028] Example: see figure 1 , figure 2 as well as image 3, a permanent magnet magneto-rheological fan clutch for an internal combustion engine, comprising a drive shaft 1 , a driven housing and an input flange 3 . The driven housing includes a left end cover 201, a housing 202 and a right end cover 203 connected in sequence, wherein the inner hole of the housing 202 is a stepped hole, the section near the left end is a large diameter section, and the section near the right end is a small diameter section. section; during specific implementation, the right end cover 203 is integrally formed with the housing 202, thereby improving the stability of the entire driven housing. The driving shaft 1 is located in the driven housing, and its two ends are respectively connected to the left end cover 201 and the right end cover 203 through bearings, and the right end of the driving shaft 1 passes through the right end cover 203 and is fixedly connected to the input flange 3 . A bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com