Activating method of solid phosphoric acid catalyst

A technology of phosphoric acid catalyst and activation method, which is applied in the field of activation of solid phosphoric acid catalyst, can solve the problems of poor repeatability of activation results, unstable activation temperature, etc., and achieve the effects of stable activation operation, stable air flow, and accurate quantification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

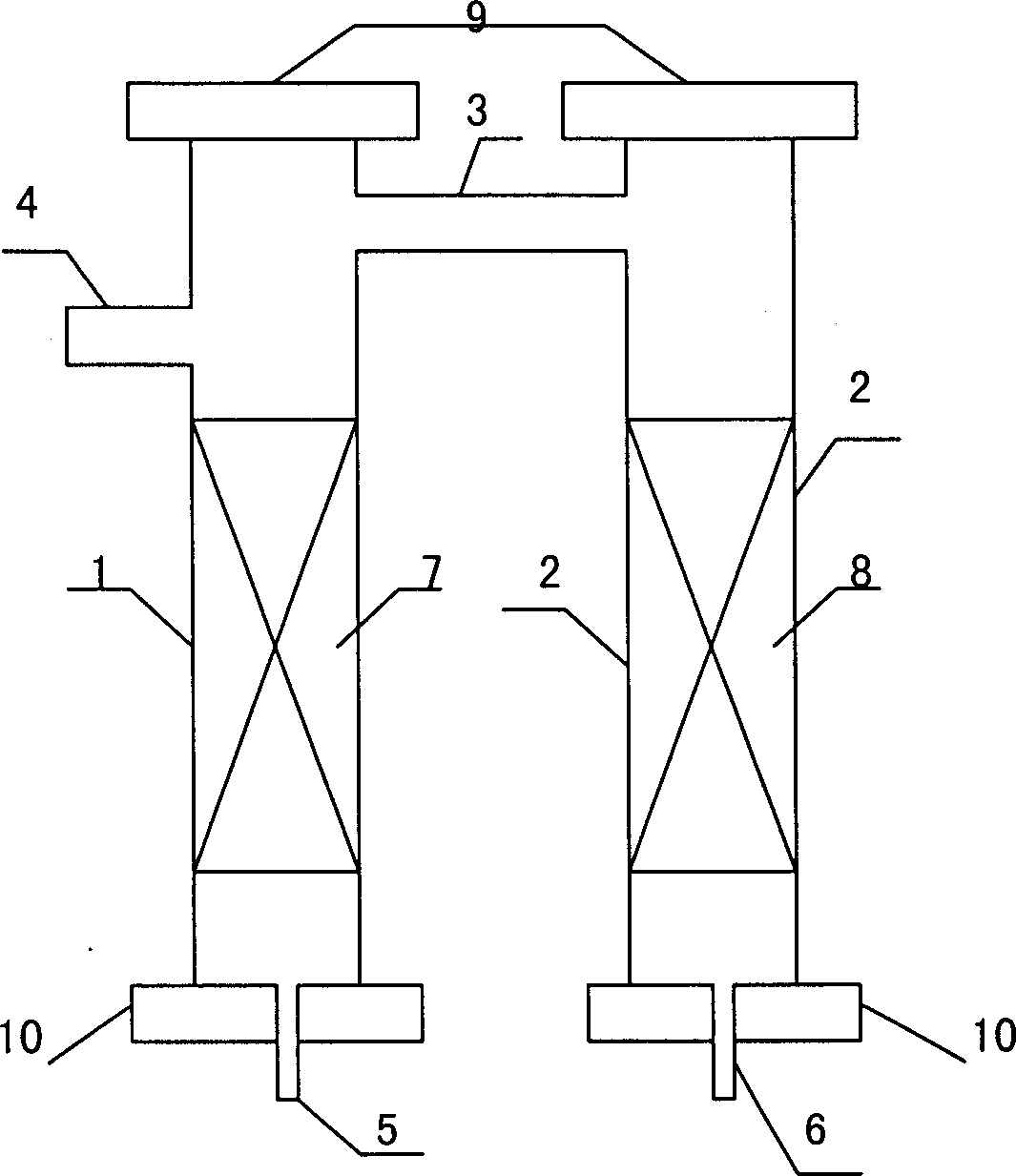

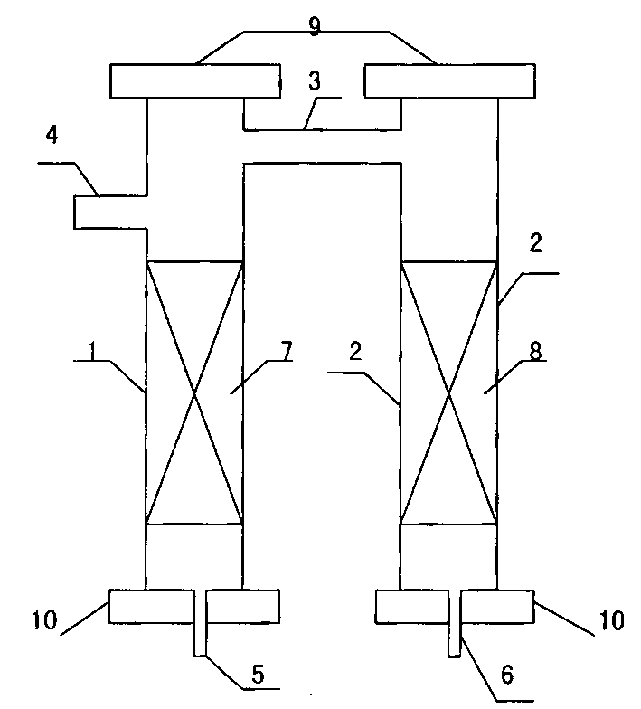

Image

Examples

Embodiment 2

[0034] The operating temperature of the packing layer 7 of the controlled packed tower is 220°C, the temperature of the catalyst bed layer 8 of the activation tower is 220°C, the operating temperature of the activation gas introduction pipe 3 is 250°C, and the water is counted as 20 moles per liter of catalyst per hour. , so that the air: water vapor molar ratio is 1:1; the activation time is 4 hours. Other conditions are with embodiment 1. The catalyst finished product that makes consists of:

[0035] SiB 0.7 (P 2 o 5 ) 1.4 ·(H 2 O) 0.75

[0036] After activation, the activity of the solid phosphoric acid catalyst is 76% in terms of propylene conversion rate, and its free phosphoric acid is calculated as P 2 o 5 The percentage by weight is calculated as 11%. [Example 3]

Embodiment 3

[0037] Control packing tower packing layer 7 operating temperature is 280 ℃, activation tower catalyst bed 8 temperature 270 ℃, activation gas inlet pipe 3 operating temperature is 280 ℃, water counts as 50 moles per liter of catalyst per hour, The air:water vapor molar ratio is 1.4:1; the activation time is 5 hours. Other conditions are with embodiment 1. The catalyst finished product that makes consists of:

[0038] SiB 1.0 (P 2 o 5 ) 1.5 ·(H 2 O) 0.9

[0039] After activation, the activity of the solid phosphoric acid catalyst is 79% in terms of propylene conversion rate, and its free phosphoric acid is calculated as P 2 o 5 The percentage by weight is calculated as 15%. 【Example 4】

Embodiment 4

[0040] Control packing tower packing layer 7 operating temperature is 300 ℃, activation tower catalyst bed 8 temperature 280 ℃, activation gas inlet pipe 3 operating temperature is 280 ℃, water counts as 70 moles per liter of catalyst per hour, The air:water vapor molar ratio is 1.7:1; the activation time is 4 hours. Other conditions are with embodiment 1. The catalyst finished product that makes consists of:

[0041] SiB 0.8 (P 2 o 5 ) 1.6 ·(H 2 O) 0.95

[0042] After activation, the activity of the solid phosphoric acid catalyst is 81% in terms of propylene conversion rate, and its free phosphoric acid is calculated as P 2 o 5 The percentage by weight is calculated as 17%. 【Example 5】

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com