Preparation method of proton exchange membrane fuel cell membrane electrode

A fuel cell membrane and proton exchange membrane technology, applied in fuel cells, battery electrodes, circuits, etc., can solve problems such as the degradation of catalytic layer and electrolyte, membrane electrode performance, etc., to improve contact performance, improve power generation performance, reduce Effect of small contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

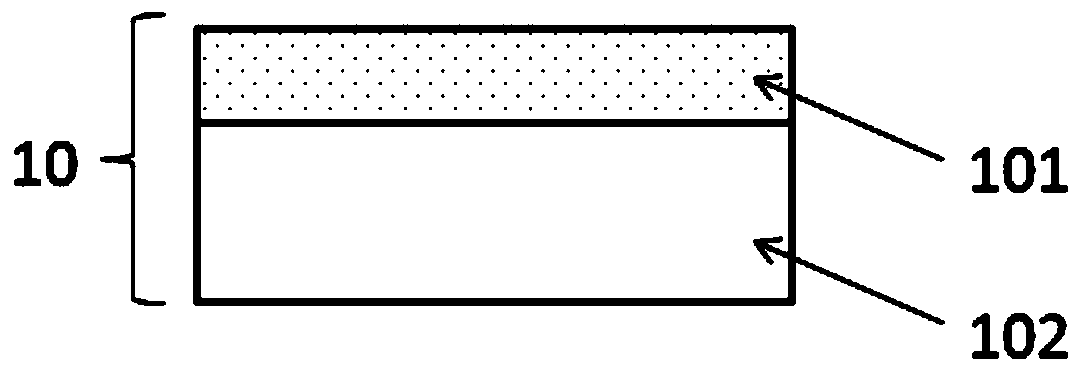

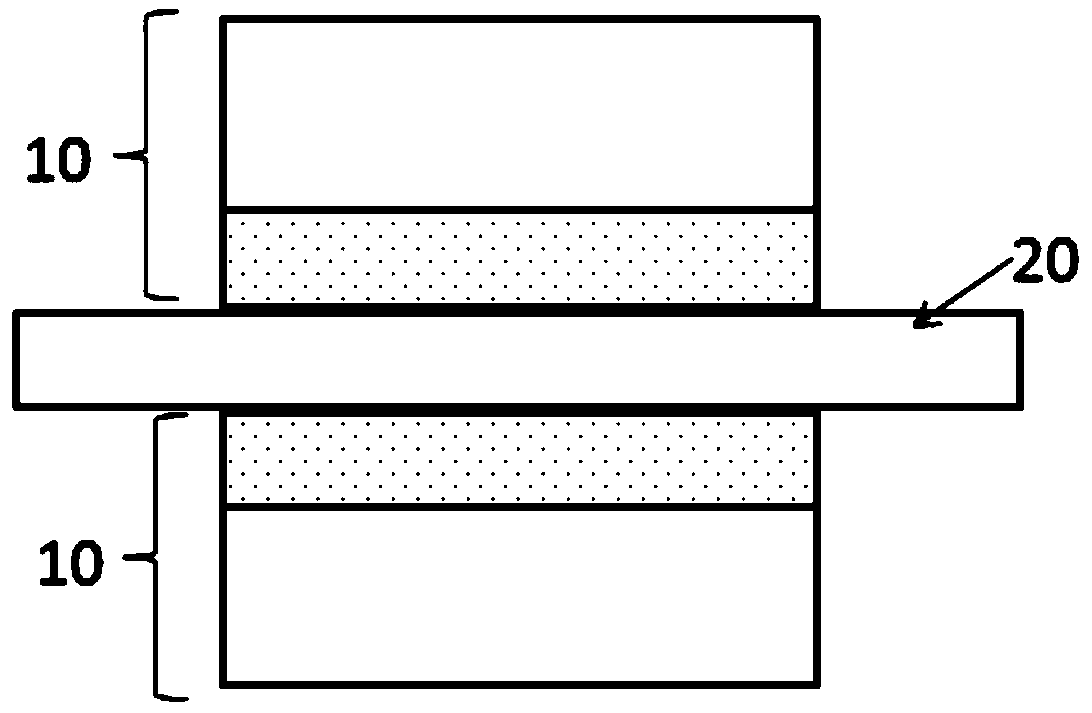

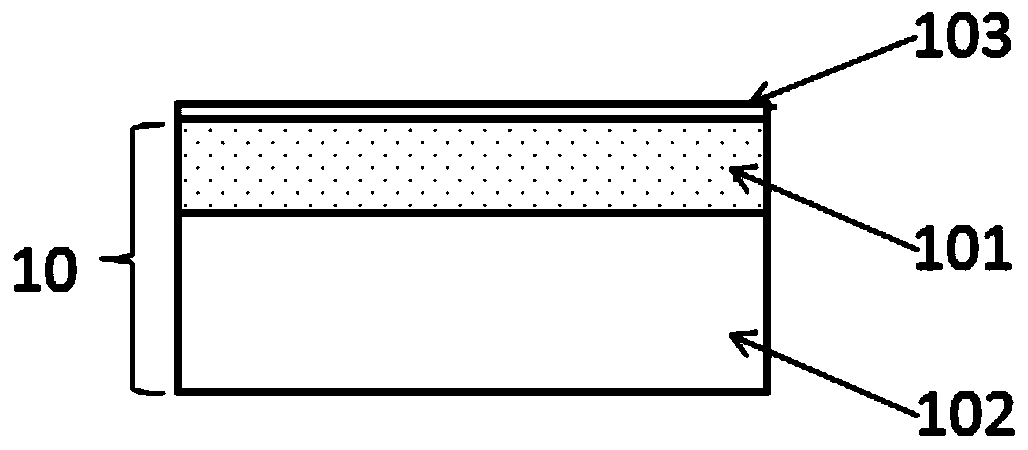

[0042] A kind of preparation method of the membrane electrode of proton exchange membrane fuel cell provided by the invention, the steps are:

[0043] a. Preparation of gas diffusion electrode

[0044] 1) Preparation of catalyst ink:

[0045]Weigh 0.5g of platinum black and mix it with 1.0g of deionized water, then carry out ultrasonication in an ice bath, set the power of the ultrasonic instrument to 3W, and the ultrasonic time is 10 minutes. By observing that there is no platinum black powder solid in the mixed solution, the solid-liquid distribution is uniform and then mixed. Finish. Then add 1.0g isopropanol and 0.5g concentration of 5wt% Nafion solution, finally add 0.21g solid content 60wt% PTFE emulsion (about 20% PTFE content in the solid after drying), after mixing, disperse by ball milling method: transfer the mixed solution into a ball mill jar, and add zirconia stirring particles (the mass ratio of zirconia stirring particles to the mixed solution is 1.5:1), and ...

Embodiment 2

[0054] A kind of preparation method of the membrane electrode of proton exchange membrane fuel cell provided by the invention, the steps are:

[0055] a. Preparation of gas diffusion electrode

[0056] 1) Preparation of catalyst ink:

[0057] Weigh 0.5g of platinum black and mix it with 1.5g of deionized water, and perform ultrasonication in an ice bath. The power of the ultrasonic instrument is set to 5W, and the ultrasonic time is 10 minutes. By observing that there is no platinum black powder solid in the mixed solution, the solid-liquid distribution is uniform and then mixed. Finish. Then add 1.33g isopropanol and 0.5g concentration of 5wt% Nafion solution, finally add 0.27g solid content 60wt% PTFE emulsion (about 24% PTFE content in the solid after drying), after mixing, disperse by ball milling method: transfer the mixed solution into a ball mill jar, and add zirconia stirring particles (the mass ratio of zirconia stirring particles to the mixed solution is 1.5:1), an...

Embodiment 3

[0066] A kind of preparation method of the membrane electrode of proton exchange membrane fuel cell provided by the invention, the steps are:

[0067] a. Preparation of gas diffusion electrode

[0068] 1) Preparation of catalyst ink:

[0069] Weigh 0.5g of platinum black and mix it with 2.0g of deionized water, then carry out ultrasonication in an ice bath, set the power of the ultrasonic instrument to 4W, and the ultrasonic time is 5 minutes. By observing that there is no platinum black powder solid in the mixed solution, the solid-liquid distribution is uniform and then mixed. Finish. Then add 2.0g isopropanol and 0.4g concentration of 5wt% Nafion solution, finally add 0.36g solid content 60wt% PTFE emulsion (about 30% PTFE content in the solid after drying), after mixing, disperse by ball milling method: transfer the mixed solution into a ball mill jar, and add zirconia stirring particles (the mass ratio of zirconia stirring particles to the mixed solution is 1.5:1), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com