Intelligent sorting AGV

An intelligent, location technology, applied in transportation, packaging, storage devices, etc., can solve the problems of high cost per shelf, poor shelf stability, low AGV running speed, etc., to reduce the cost per shelf, and achieve a high degree of automation. , the effect of high picking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

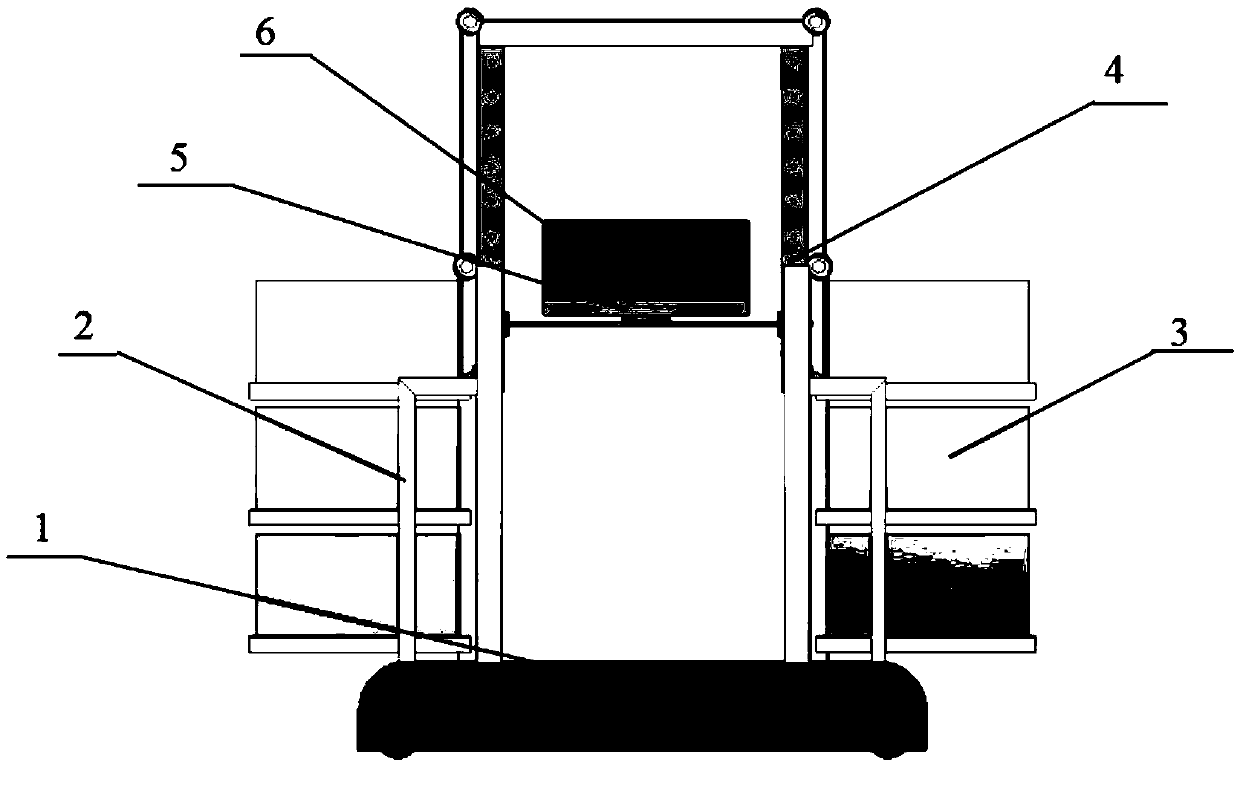

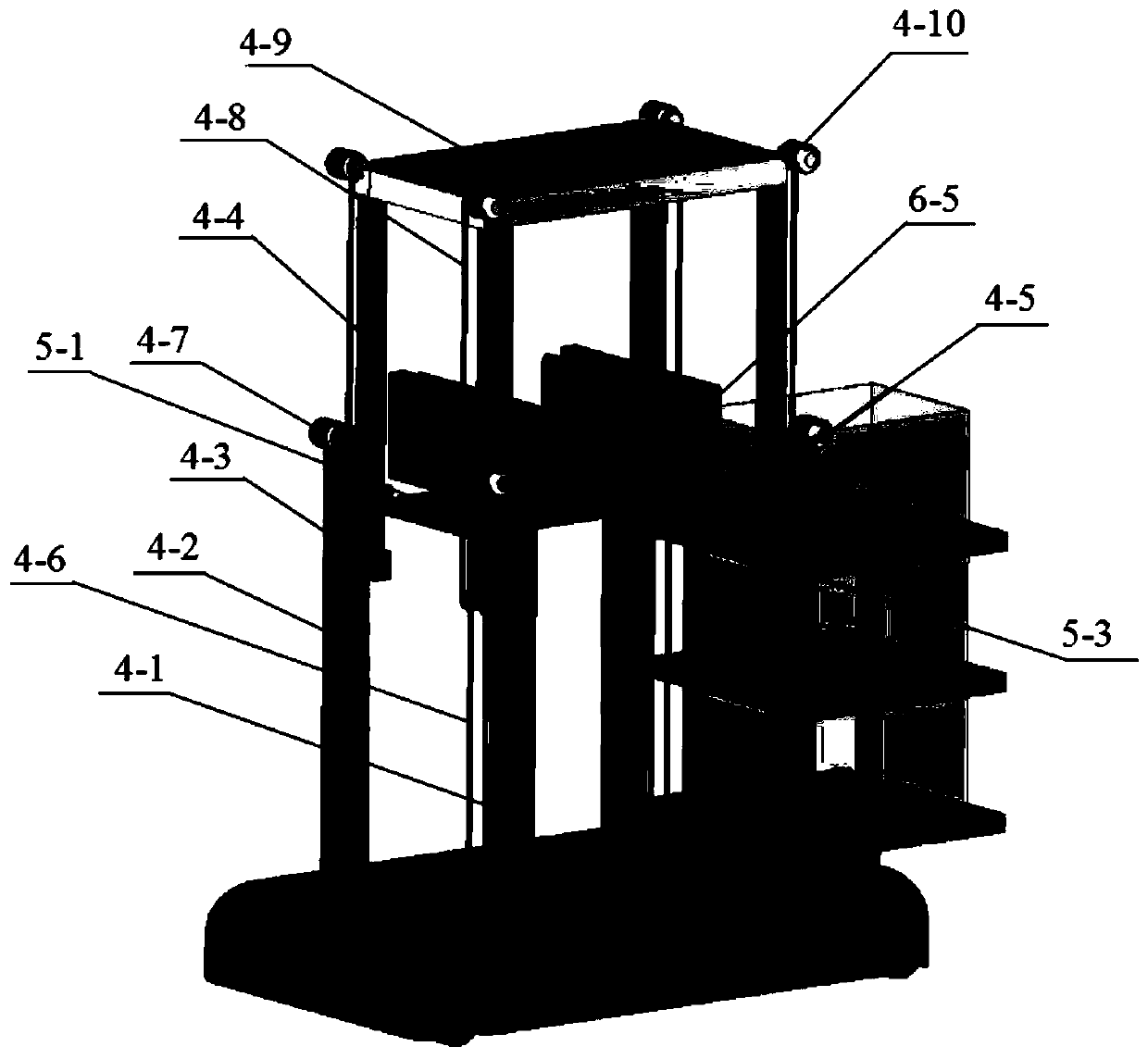

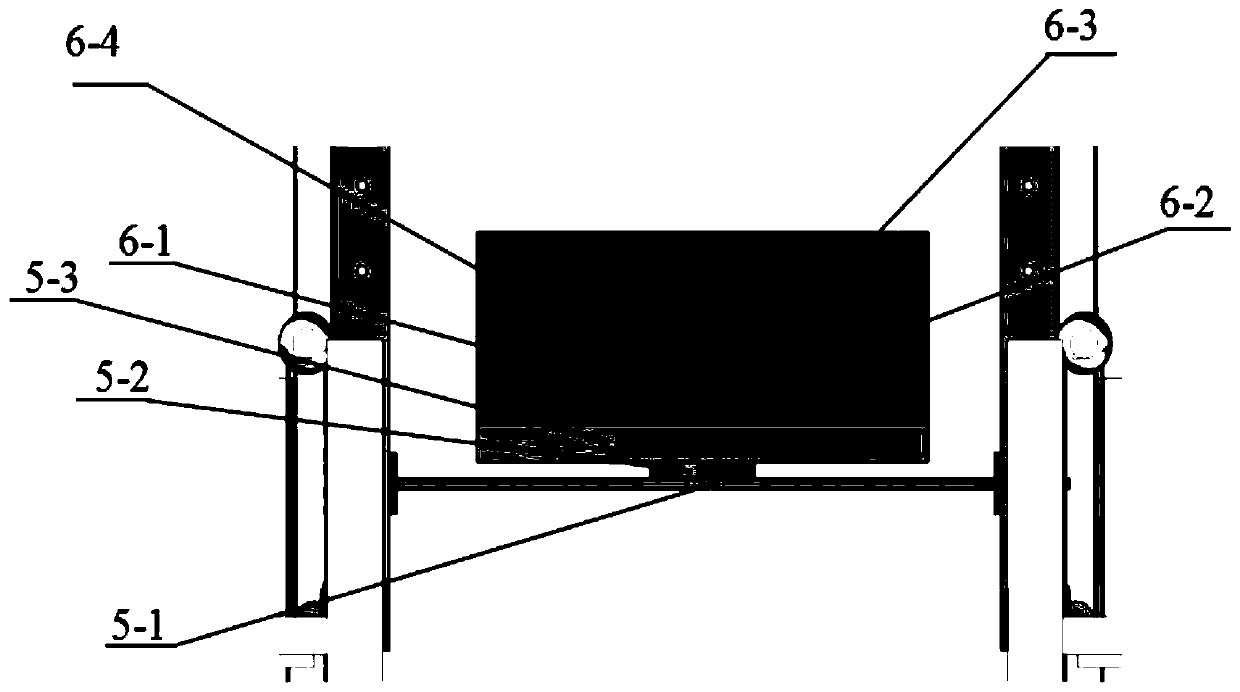

[0029] Embodiment 1: This intelligent picking AGV, such as Figure 1~3 As shown, it includes AGV car 1, cargo space bracket 2, material box 3, lifting system 4, cargo platform 5, and cargo fork 6;

[0030] The two ends or one end of the AGV car 1 are installed with a cargo space bracket 2, the material box 3 is placed on the cargo space bracket 2, the lifting system 4 is installed on the AGV vehicle 1, and the cargo platform 5 is installed on the top of the lifting system 4. Said pallet fork 6 is installed on the loading platform 5.

[0031] The AGV car 1 includes a car body, a power transmission device, a brake device, a stand-alone control system, a cargo location management system, a navigation and positioning system, a communication system and a power supply system; the bottom of the car body is provided with a driving wheel, and the power transmission device, brake The devices are respectively installed on the car body and connected to the driving wheels respectively, an...

Embodiment 2

[0044] Embodiment 2: The structure of this embodiment is the same as that of Embodiment 1, the difference is that the first-level lifting transmission mechanism and the second-level lifting transmission mechanism are chain transmission mechanisms, and the communication and data between AGV vehicle 1 and external equipment through wireless WIFI technology Interaction, the outer surface of the material box 3 is affixed with an RFID chip that records the information of the goods in the box, the reader 6-2 is an RFID reader, and the way the telescopic clamp 6-3 clamps the material box 3 is a clamping type .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com