Cone yarn unwinding device suitable for core-spun yarn production

A core-spun wire and unwinding technology, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material processing, can solve the problems of reducing the production rate, affecting the production of parallel lines, and hanging yarns, and achieves a smooth surface. Good quality, not easy to fall off or slide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

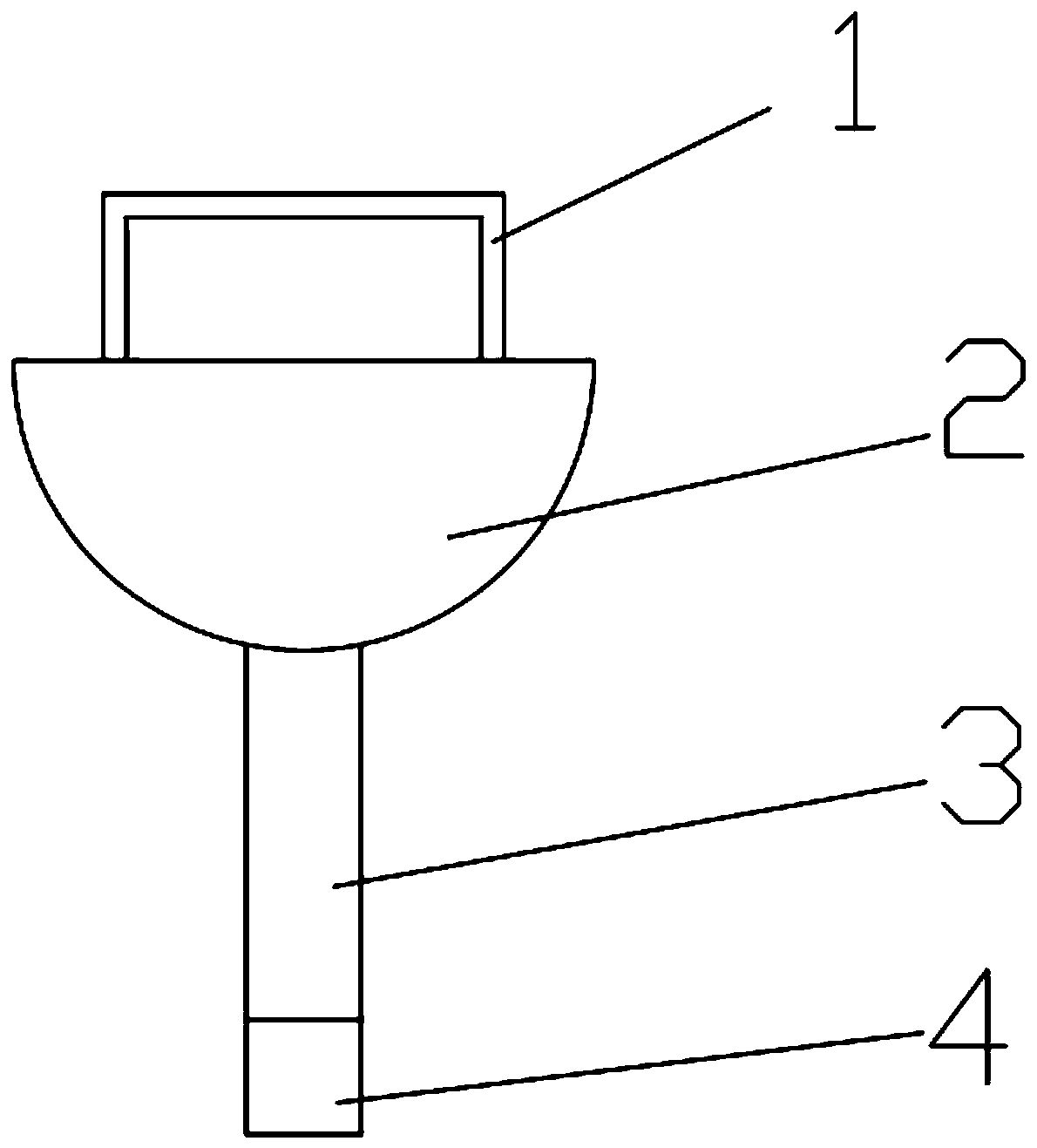

[0009] As shown in the figure: a bobbin unwinding device suitable for core-spun yarn production, characterized in that it includes a handle 1, a hemispherical unwinding disc 2, and a connecting rod 3; the handle 1 and the hemispherical unwinding disc 2 The connecting rod 3 is connected with the hemispherical unwinding disk 2; the lower end of the connecting rod 3 is provided with a strong magnet 4; the hemispherical unwinding disk 2 is made of metal material, and its surface is hard chrome-plated.

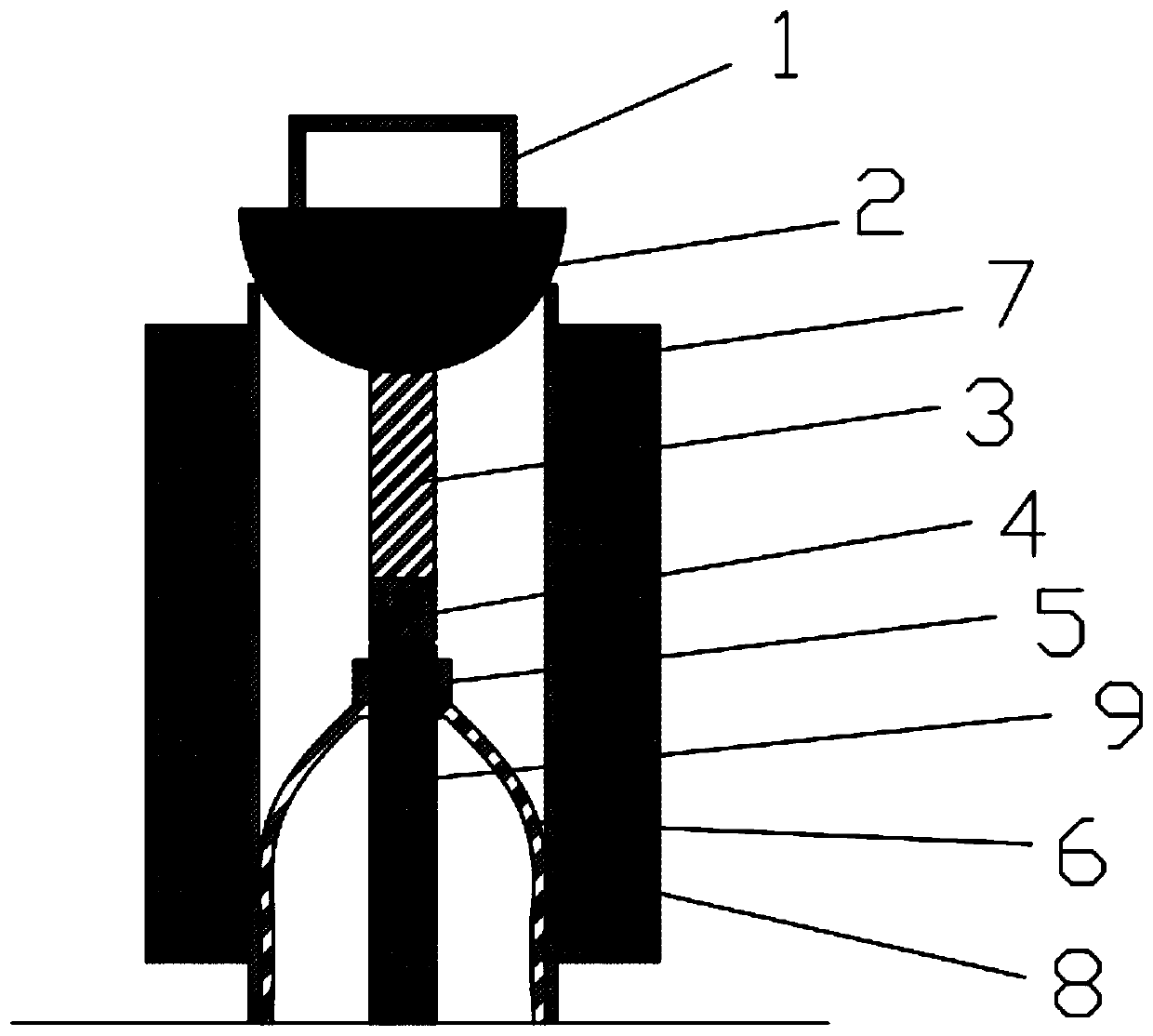

[0010] Use of the present invention: as figure 2 As shown, adjust the nut 5 of the package yarn tension sleeve 6, so that the expansion sleeve 6 can be stretched to the extent that the bobbin 7 can be fixed, place the package yarn 8 on the package yarn tension sleeve 6, and then hold the device by hand Put the device into the bobbin 7 of the bobbin 8 by the handle 1. Since the hemispherical unwinding disc 2 and the strong magnet 4 are installed, the device will be automatically ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com