Anisotropic cesium-lead-chlorine perovskite micron sheet and preparation method thereof

An anisotropic, perovskite technology, applied in chemical instruments and methods, lead compounds, nanotechnology, etc., can solve the problems of unfavorable intrinsic properties of perovskite, residual organic matter, etc., to achieve adjustable size and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) 27.8mg PbCl 2 , 5.04 mg CsCl, and 20 mg CH 3 (CH 2 ) 3 NH 3 I was dissolved in 1ml DMSO respectively, and 0.1ml PbCl 2 DMSO solution, 0.5ml CsCl in DMSO solution, 0.1ml CH 3 (CH 2 ) 3 NH 3 The DMSO solution of I was mixed at 25°C for 5 h to obtain a precursor solution;

[0023] 2) Si / SiO 2 The substrate was preheated at 70°C for 20 minutes, and 50 μL of the precursor solution was dropped onto the hot substrate, and continued heating for 20 minutes;

[0024] 3) Rinse the substrate with ethyl acetate to obtain CsPbCl with a lateral dimension of 1000 μm and a thickness of 10 μm 3 Perovskite microsheets.

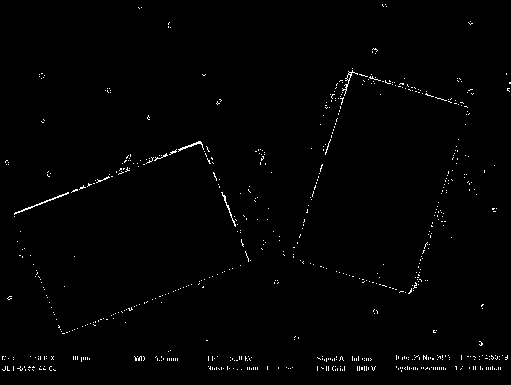

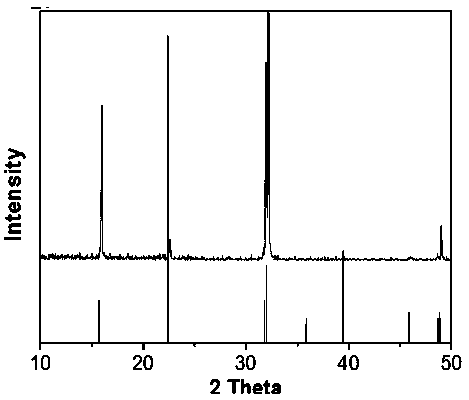

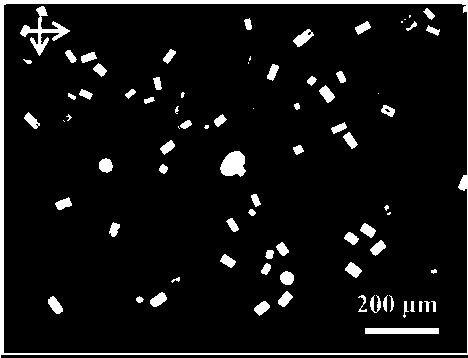

[0025] For the prepared CsPbCl 3 Scanning electron microscopy, X-ray diffraction and polarizing microscopy of perovskite microflakes for analysis of CsPbCl 3 The structural characteristics of perovskite microsheets, the results are as follows:

[0026] figure 1 It is the scanning electron microscope image of the cesium lead chloride perovskite microsheet...

Embodiment 2

[0031] 1) 27.8mg PbCl 2 , 5.04 mg CsCl, and 20 mg CH 3 (CH 2 ) 3 NH 3 I was dissolved in 1 ml DMSO respectively, and 0.1 ml PbCl 2 DMSO solution, 0.16ml CsCl in DMSO solution, 0.1ml CH 3 (CH 2 ) 3 NH 3 The DMSO solution of I was mixed at 60°C for 0.1 h to obtain a precursor solution;

[0032] 2) Preheat the Si substrate at 100°C for 1 min, take 5 μL of precursor solution dropwise onto the hot substrate, and continue heating for 5 min;

[0033] 3) Rinse the substrate with isopropanol to obtain anisotropic CsPbCl with a lateral dimension of 1 μm and a thickness of 50 nm 3 Perovskite microsheets.

Embodiment 3

[0035] 1) 27.8mg PbCl 2 , 5.04 mg CsCl, and 20 mg CH 3 (CH 2 ) 3 NH 3 I was dissolved in 1ml DMSO respectively, and 0.1ml PbCl 2 DMSO solution, 0.5ml CsCl in DMSO solution, 0.1ml CH 3 (CH 2 ) 3 NH 3 The DMSO solution of I was mixed at 40°C for 3 h to obtain a precursor solution;

[0036] 2) Si / SiO 2 The substrate was preheated at 80°C for 10 minutes, and 10 μL of the precursor solution was dropped onto the hot substrate, and continued heating for 10 minutes;

[0037] 3) Rinse the substrate with toluene to obtain anisotropic CsPbCl with a lateral dimension of 100 μm and a thickness of 5 μm 3 Perovskite microsheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com