Preparation of chitin lyotropic liquid crystal

A technology of lyotropic liquid crystals and chitin, which is applied in the direction of liquid crystal materials, chemical instruments and methods, and bulk chemical production, can solve the problems of unrecyclable solvents, inevitable degradation, and low viscosity, and achieve simple preparation methods and solution systems. Stable and cost-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

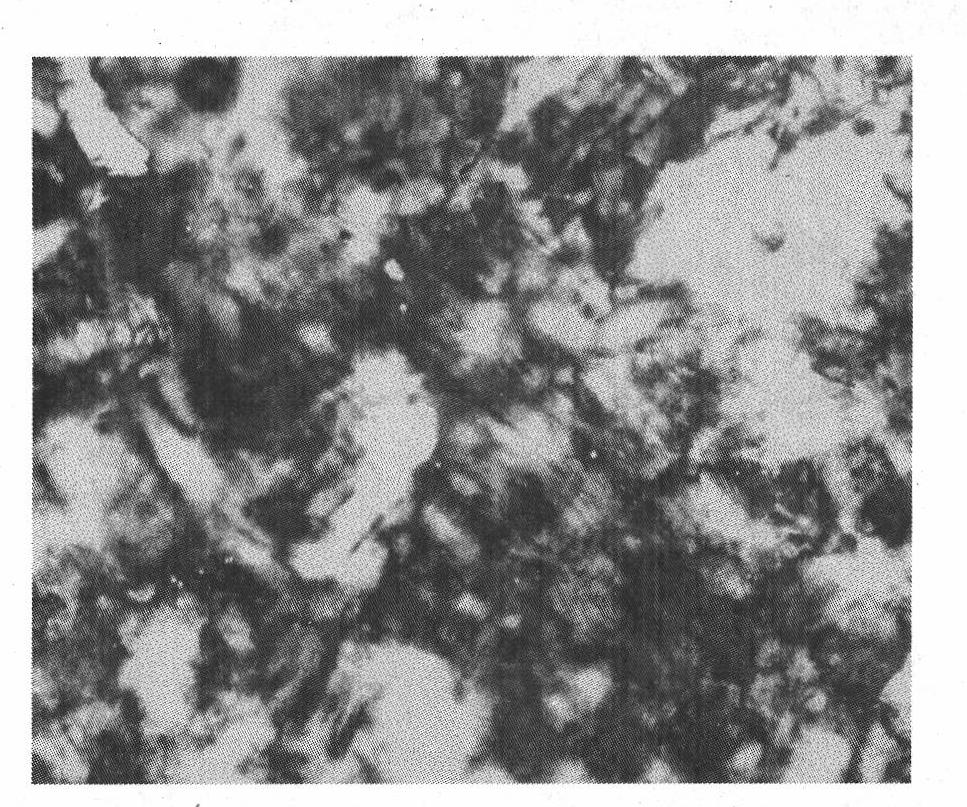

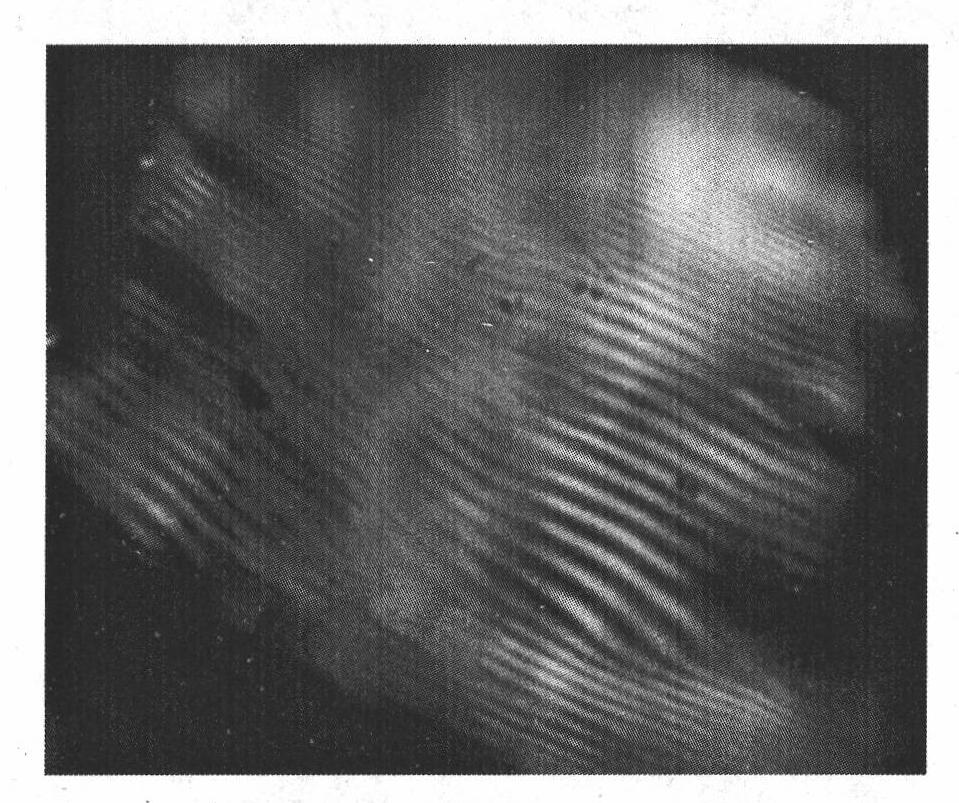

[0027] The ionic liquid 1-allyl-3-methylimidazole hydrochloride (AMIMCl) was placed in a petri dish, placed in a freeze dryer for 24 hours, and then placed in a vacuum oven at 110°C for 24 hours to remove moisture. Pour 1.035g of AMMCl into a 5ml graduated test tube with a stopper in an almost anhydrous environment, add 0.066g of anhydrous LiCl (6wt%), stir evenly and place it in an oven at 100°C for 1 hour until LiCl is completely dissolved to obtain a transparent solution. Weigh 0.034g Chitin (3wt%) was added to the test tube, and after mixing evenly, the test tube was placed in a vacuum oven at 100°C. After 24 hours, samples were taken between two glass slides to form a liquid crystal cell, sealed with wax, and left to stand for 1 hour. Observed under a polarizing microscope at 20°C planar liquid crystal texture, (see figure 1 ), a typical fingerprint-like texture can be observed in local areas (see figure 2 ), both textures are cholesteric liquid crystals.

Embodiment 2

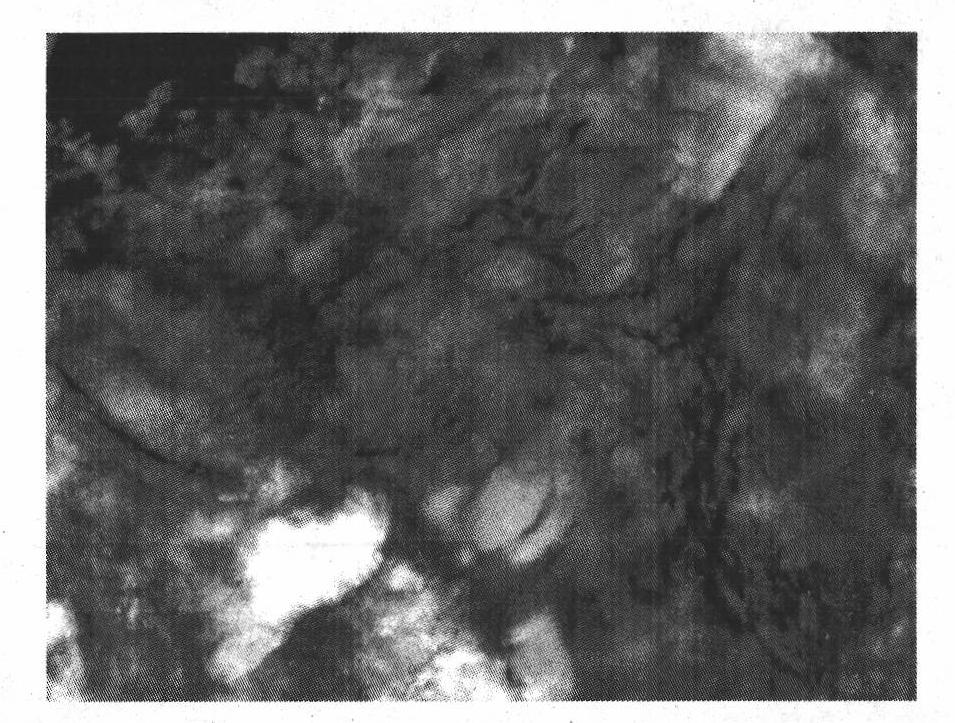

[0029] Place the ionic liquid 1-butyl-3-methylimidazole hydrochloride (BMIMCl) in a petri dish, freeze-dry it in a freeze dryer for 24 hours, and then dry it in a vacuum oven at 110°C for 48 hours in a basically anhydrous environment. Get 1.255g BMMCl and pour it into a 5ml stoppered scale test tube, add 0.081g anhydrous urea (CO(NH 2 ) 2 , 6wt%), stirred evenly and placed in a 110°C oven for 0.5h until the urea was completely dissolved to obtain a transparent solution. Weighed 0.07g chitin (5wt%) and added it to the test tube. After mixing evenly, place the test tube in a 100°C vacuum oven After 24 hours, samples were taken between two glass slides to form a liquid crystal cell, sealed with wax, and left to stand for 1 hour. Planar liquid crystal texture was observed under a polarizing microscope at 20°C (see image 3 ), a typical fingerprint-like texture can be observed in the local area ( Figure 4 ), both textures are cholesteric liquid crystals.

Embodiment 3

[0031] The ionic liquid 1-ethyl-3-methylimidazole bromide (EMIMBr) was placed in a petri dish, placed in a freeze dryer for 24 hours, and then placed in a vacuum oven at 110°C for 24 hours in a vacuum-dried environment. Pour 1.076g of EMIMBr into a 5ml graduated test tube with stopper, add 0.096g of anhydrous LiCl (9wt%), stir evenly, and then place it in an oven at 100°C for 0.5h until LiCl is completely dissolved in the ionic liquid to obtain a transparent solution. Weigh 0.082g Chitin (7wt%) was added to the test tube, and after mixing evenly, the test tube was placed in a vacuum oven at 100°C. After 48h, the sample was taken between two glass slides to form a liquid crystal cell, sealed with wax, and left to stand for 1h, and observed under a polarizing microscope at 20°C. Planar liquid crystal texture (cholesteric phase), a typical fingerprint-like texture can be observed in local areas, and both textures are cholesteric liquid crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com