Laminated glass coating equipment

A laminated glass and coating technology, which is applied in the field of laminated glass coating equipment, can solve problems such as inability to scrape and brush coating, and achieve the effects of improving efficiency, increasing contact area, and strengthening structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

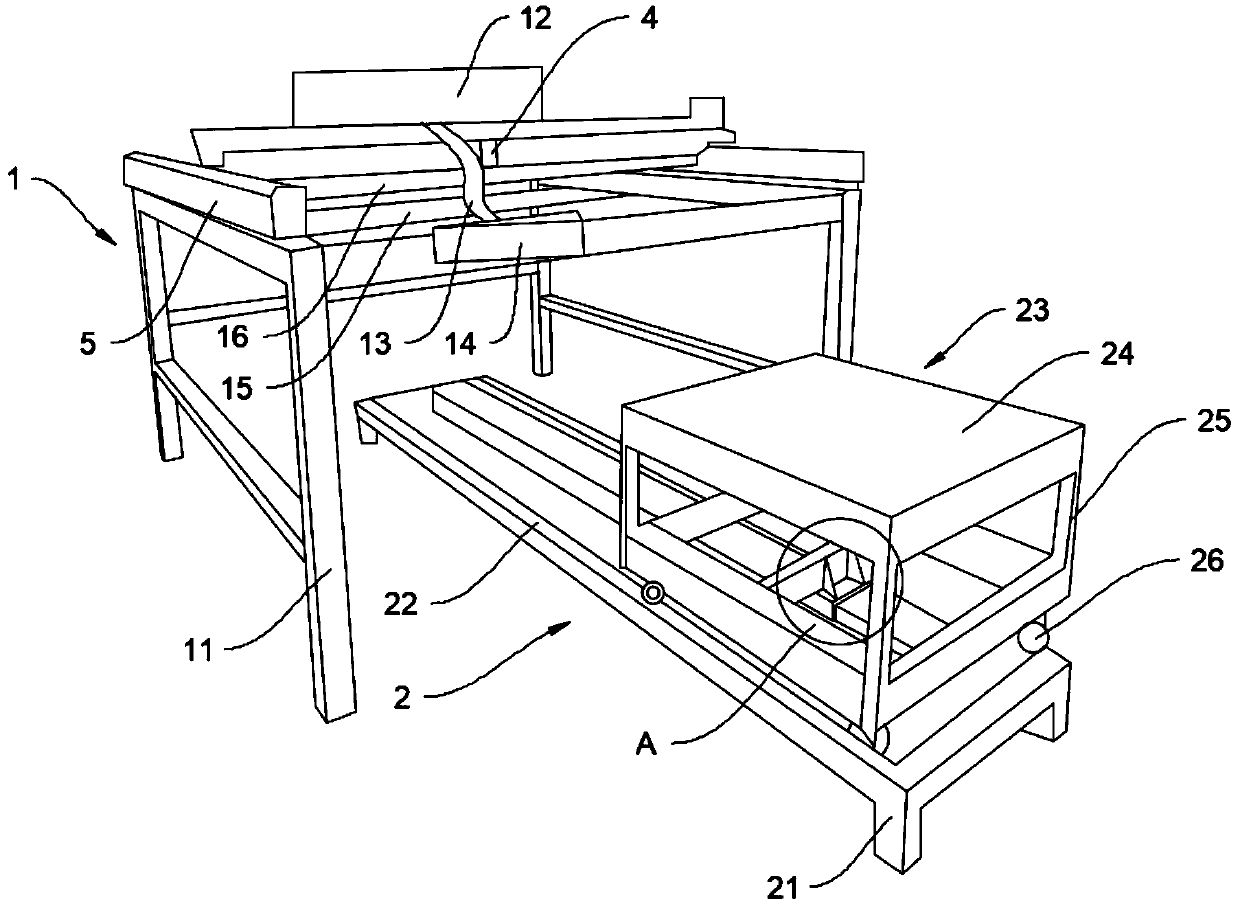

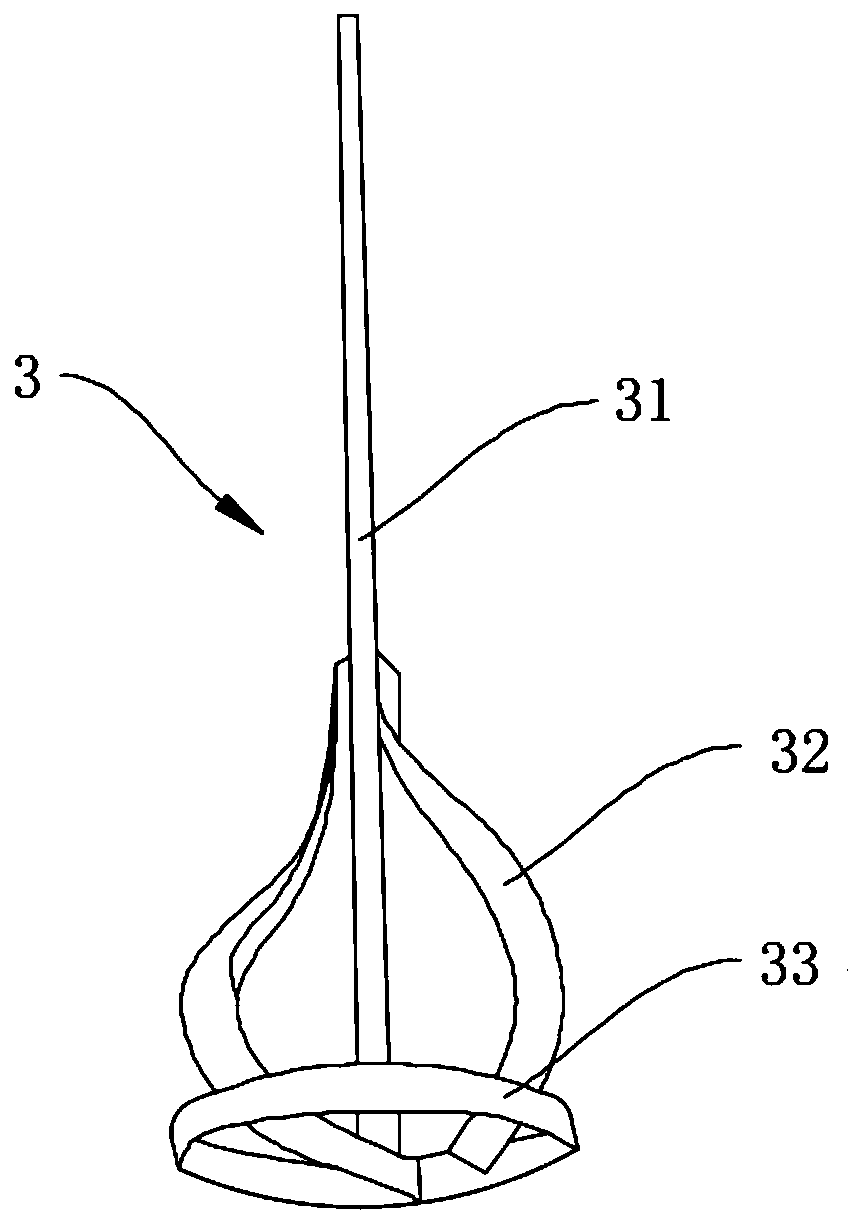

[0026] like Figure 1-4 As shown, a laminated glass coating equipment includes a first workbench 1 for coating and a second workbench 2 for carrying laminated glass, the first workbench 1 includes a frame 11, and the machine The frame 11 is provided with a paint box 12 to accommodate the paint, and the inside of the paint box 12 is provided with a plurality of stirring devices 3 driven by a motor, and the paint box 12 is connected with a spray gun 14 through a hose 13, and the frame 11 is also connected with a brush plate 15 and a scraper 16, and the second workbench 2 includes a support 21, a slide rail 22 and a dolly 23, and the dolly 23 includes a supporting platform 24, a vehicle frame 25 and wheels 26 , and the wheels 26 slide on the slide rails 22 .

[0027] Working process of the present invention is as follows:

[0028] When in use, first place the laminated glass to be coated on the supporting platform 24 of the trolley 23, and the trolley 23 can be provided with a ...

Embodiment 2

[0031] This embodiment focuses on the improvements compared with the above-mentioned embodiments, and the similarities will not be repeated. In this embodiment, the second workbench 2 also includes guide rails 27, and the trolley 23 is provided with guide rails. 27 fit guide sleeve 28. That is to say, setting the guide sleeve 28 on the guide rail 27 can not only prevent the wheels 26 of the trolley 23 from breaking away from the slide rail 22, but also enable the trolley 23 to slide on the slide rail 22 more smoothly, which is beneficial to improve the safety of the laminated glass. coating efficiency.

[0032] Further, reinforcing ribs 29 are provided on the guide sleeve 28 . Such a structural design can strengthen the structural strength of the guide sleeve 28 , so that the trolley 23 can slide on the slide rail 22 more smoothly.

Embodiment 3

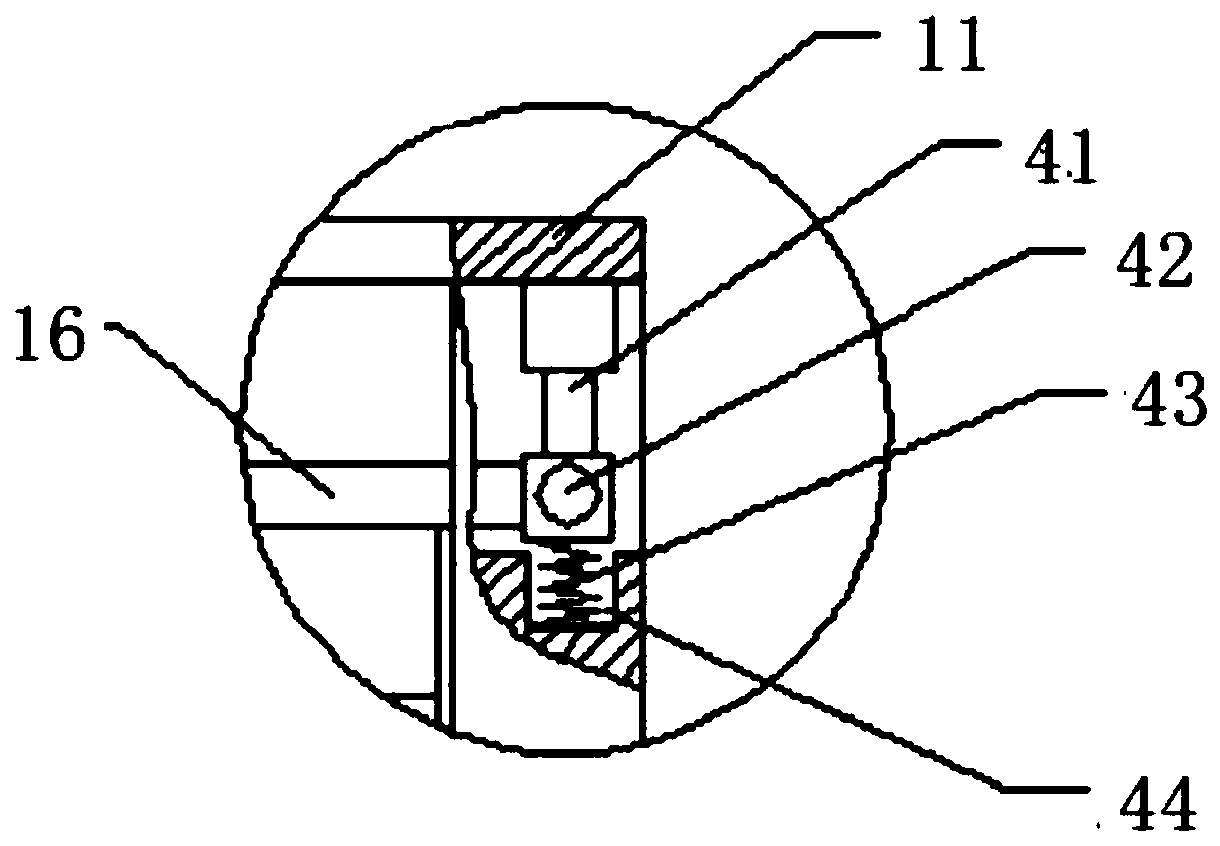

[0034] This embodiment focuses on the improvements compared with the above-mentioned embodiments, and the similarities will not be repeated. In this embodiment, the telescopic rod 4 is connected to the frame 11, and the telescopic rod 4 is connected to the scraper 16. Connected, the telescopic rod 4 is a hollow structure with a screw nut mechanism inside. That is to say, the scraper 16 can be adjusted up and down, so that the scraper 16 can flexibly further coat the paint on the surface of the laminated glass, which is beneficial to improve the coating effect on the surface of the laminated glass.

[0035] Further, the lead screw and nut mechanism inside the telescopic rod 4 includes a cylinder 41 and a nut 42, a groove 43 is arranged under the nut 41, a spring 44 is arranged in the groove 43, and one end of the spring 44 is connected to the The nut 42 is connected, the other end is connected with the bottom of the groove 43, the nut 42 is connected with the cylinder 41 above,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com