A temperature-resistant and salt-resistant high-expansion plugging agent for sealing large cracks and its preparation method

一种耐温抗盐、高膨胀的技术,应用在化学仪器和方法、粘合剂类型、钻孔的组合物等方向,能够解决结构破坏、不利环境保护、高毒性等问题,达到良好抗温、良好封堵效果的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

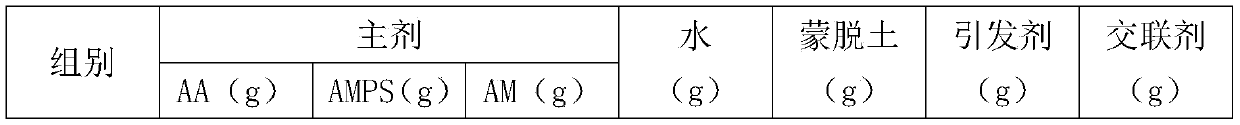

[0025] A1: Preparation of montmorillonite dispersion system

[0026] Add 10 g of montmorillonite to 82.2 g of aqueous solution which is being stirred under a stirrer and stir for 5 hours. The rotational speed of the stirrer is 200 r / min, so that the montmorillonite can be well dispersed in water to obtain a montmorillonite dispersion system.

[0027] A2: Preparation of main agent solution

[0028] The main agent prepared by 3g acrylamide (AM), 2g acrylic acid (AA) and 1g 2-acrylamide-2-methylpropanesulfonic acid (AMPS), 0.8g phenolic crosslinking agent and 1g concentration of 1% azo Diisobutyronitrile initiator is added to the montmorillonite dispersion system prepared in step A1, stirred evenly with a glass rod, so that the main agent, crosslinking agent, and initiator can be well dissolved in the montmorillonite dispersion system to obtain the main agent solution.

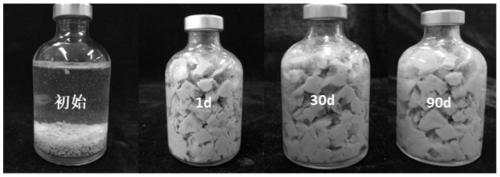

[0029] A3: Preparation of blocking agent

[0030] Put the prepared solution into the aging tank, tighten th...

Embodiment 2

[0036] A1: Preparation of montmorillonite dispersion system

[0037] Add 6g of montmorillonite into 83.2g of the stirring aqueous solution, and stir for 4h to 5h, so that the montmorillonite is well dispersed in the water to obtain a montmorillonite dispersion system.

[0038] A2: Preparation of main agent solution

[0039] The main agent prepared by 4.5g acrylamide (AM), 1.5g 2-acrylamide-2-methylpropanesulfonic acid (AMPS) and 3g acrylic acid (AA), 0.8g phenolic cross-linking agent and 1g concentration of 1% coupling The nitrogen diisobutyronitrile initiator is added to the montmorillonite dispersion system prepared in step A1, and stirred evenly, so that the main agent, crosslinking agent, and initiator can be well dissolved in the montmorillonite dispersion system to obtain a main agent solution.

[0040] A3: Preparation of blocking agent

[0041] After putting the prepared solution into the aging tank, tighten the bolts of the aging tank to seal it, put it in a 120°C ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com