Electric desalting equipment and method for crude oil

A technology for electric desalination and crude oil, which is applied in the fields of electric/magnetic dehydration/emulsification, petroleum industry, and hydrocarbon oil treatment. It can solve problems such as electrode short circuit, solve poor stability, solve the effect of electric field effect, and reduce oil content. effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

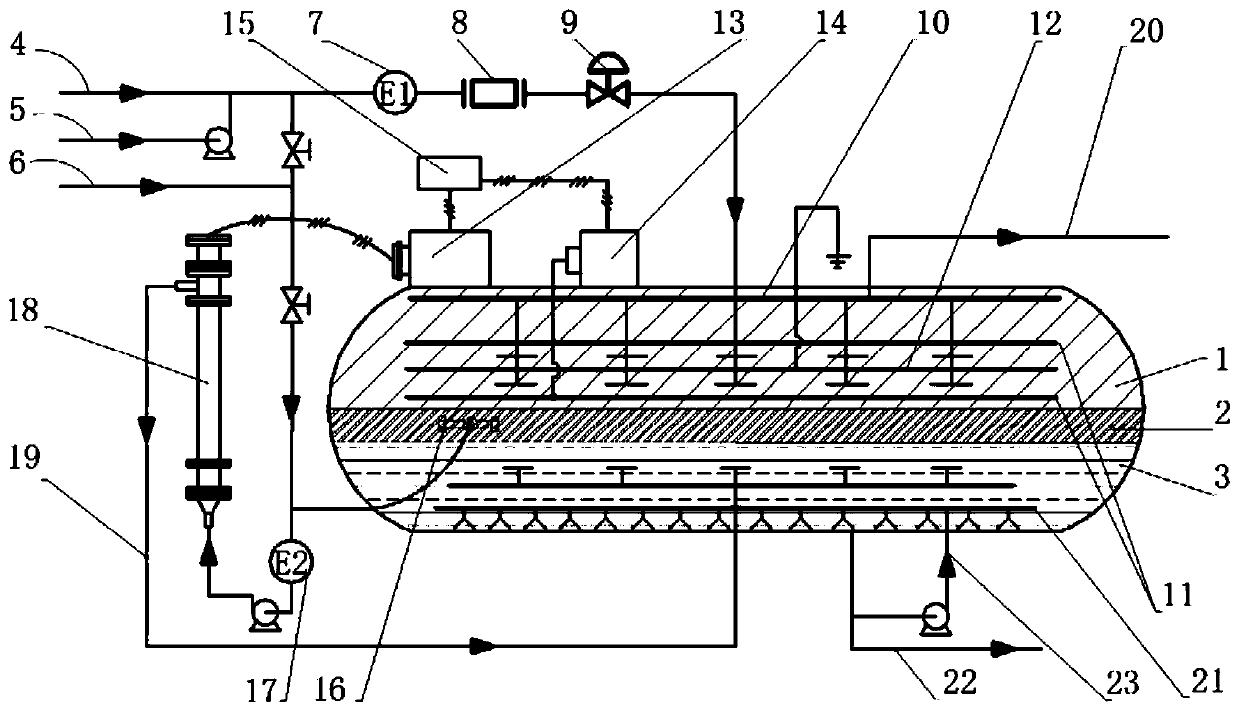

[0028] The crude oil electric desalting equipment of the present invention, its preferred embodiment is:

[0029] include:

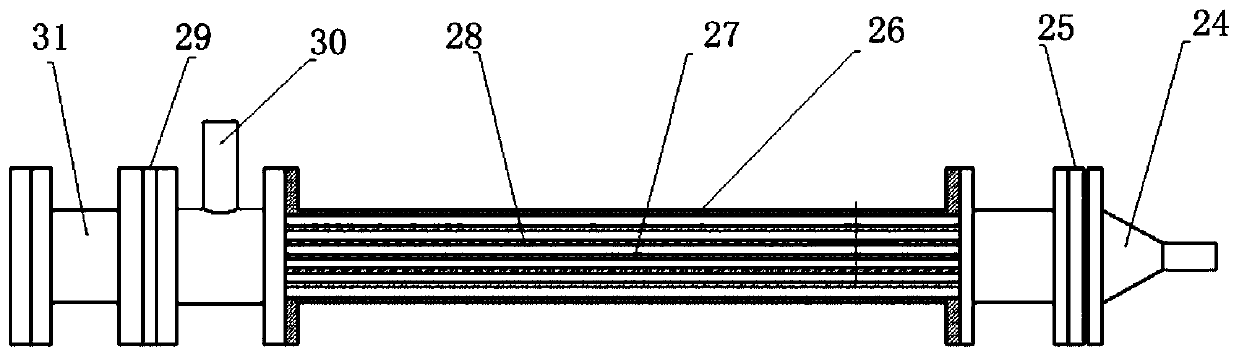

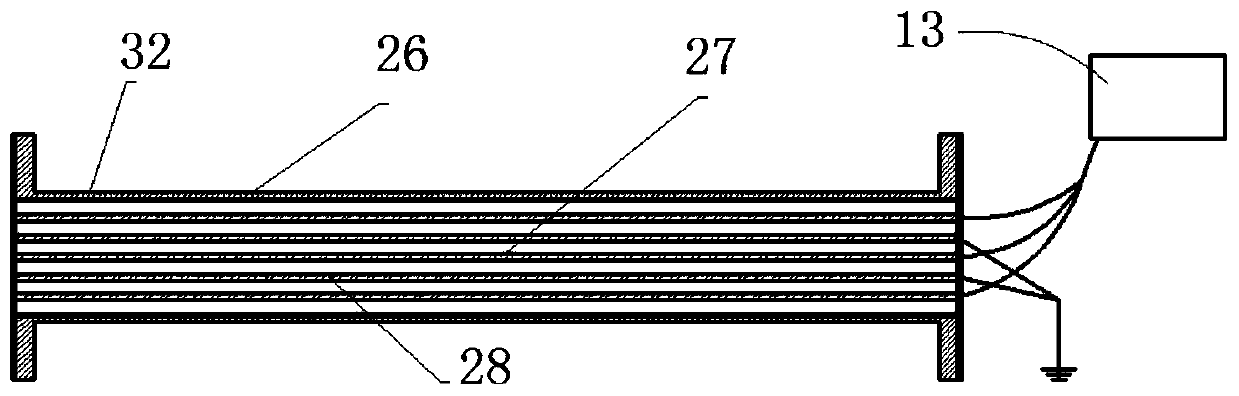

[0030] High-frequency / high-voltage pulsed AC power supply system, electric desalter, floating emulsified oil collector, oil incoming pipeline, oil pumping pipeline, reinjection pipeline, chemical dosing pipeline, heating equipment and compact tubular electric field demulsifier;

[0031] The high-frequency / high-voltage pulsed AC power system is used in conjunction with the electric desalter and the compact tubular electric field demulsifier;

[0032] The incoming oil pipeline is arranged on the upper part of the electric desalter, and is connected to the top distributor in the electric desalter, and a demulsification electrode is arranged below the top distributor;

[0033] The electric desalter consists of an oil phase layer, an emulsion layer, and a water phase layer from top to bottom, and the floating emulsified oil collector is set in the emulsion l...

specific Embodiment

[0060] Such as figure 1 As shown, the crude oil to be treated in the crude oil pipeline 4 and the dilution water in the water injection pipeline 5 are mixed through the static mixer 8 and the mixing valve 9. An appropriate amount of demulsifier is added to the mixed solution, and then the temperature of the mixed solution is moderately raised through the heat exchange device 7 . The mixed liquid is directly distributed to the electric field action area through the top distributor 10, and the demulsification occurs in the electric field area formed between the high voltage electrode 11 and the ground electrode 12 of the electric desalter, and then sedimentation and stratification occur under the action of gravity, from the top From bottom to bottom, it is divided into oil phase layer 1, emulsion layer 2 and water phase layer 3. During the working process of the electric desalter, the emulsion at the oil-water interface is extracted by the floating emulsified oil collector 16, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com