Multi-burner overhead entrained-flow bed gasification furnace

An entrained bed and gasifier technology, applied in the field of entrained gasifier, can solve the problems of poor atomization effect, long operation period, safety risks, etc. The effect of preventing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

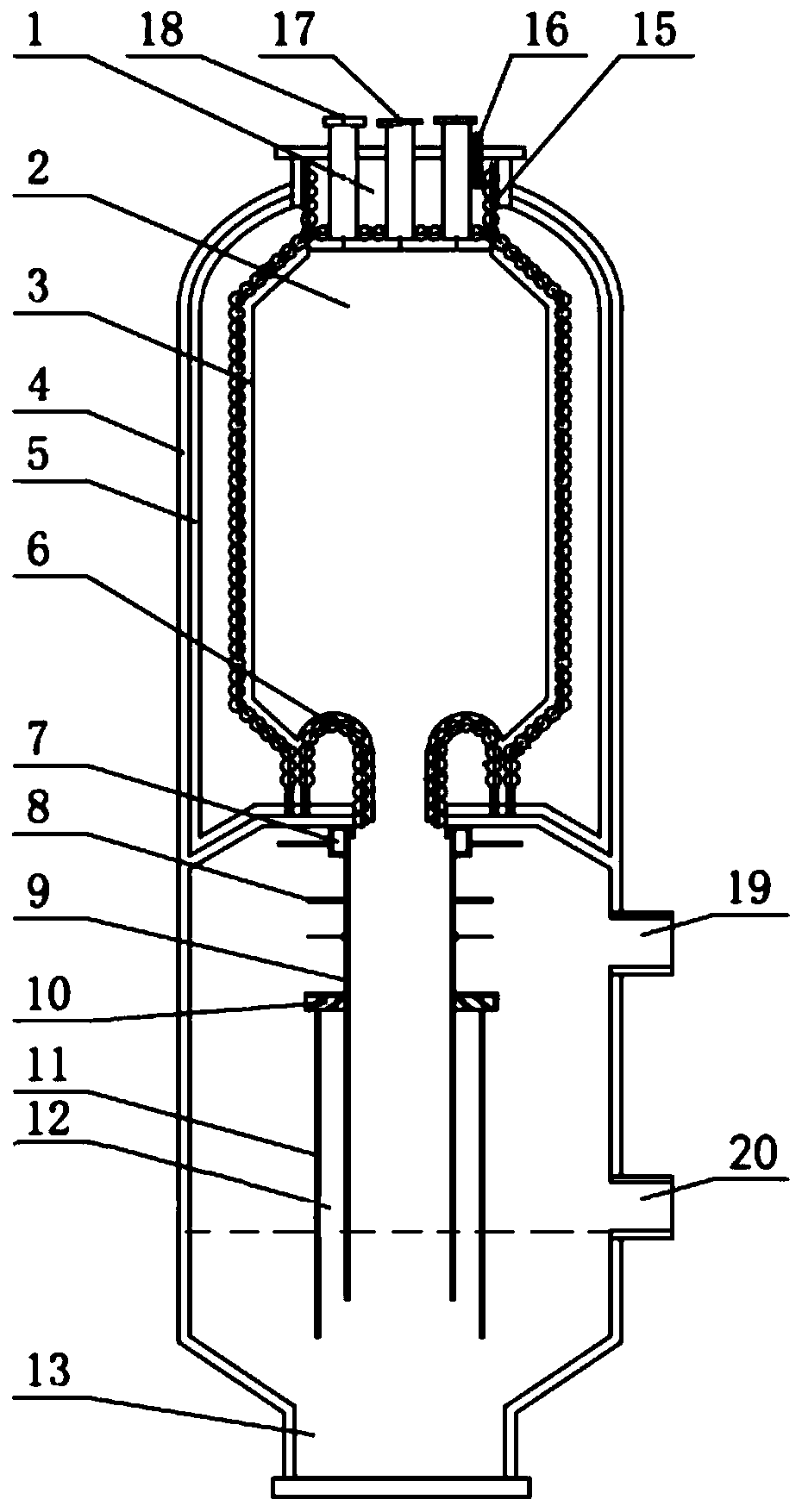

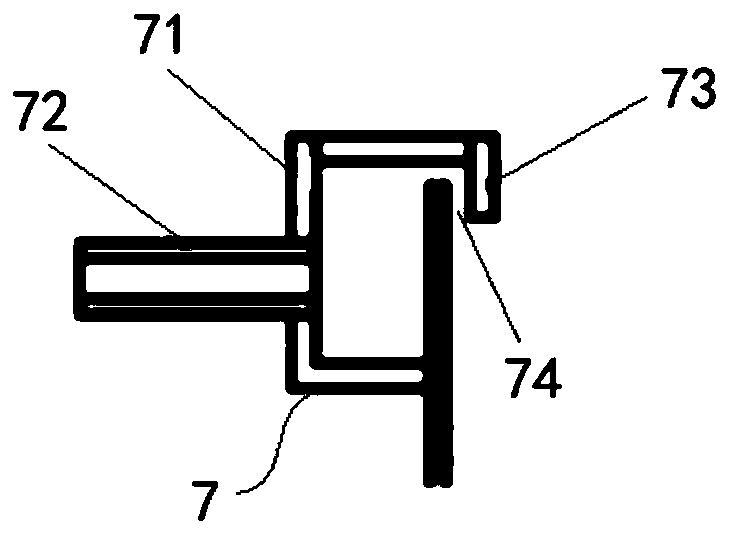

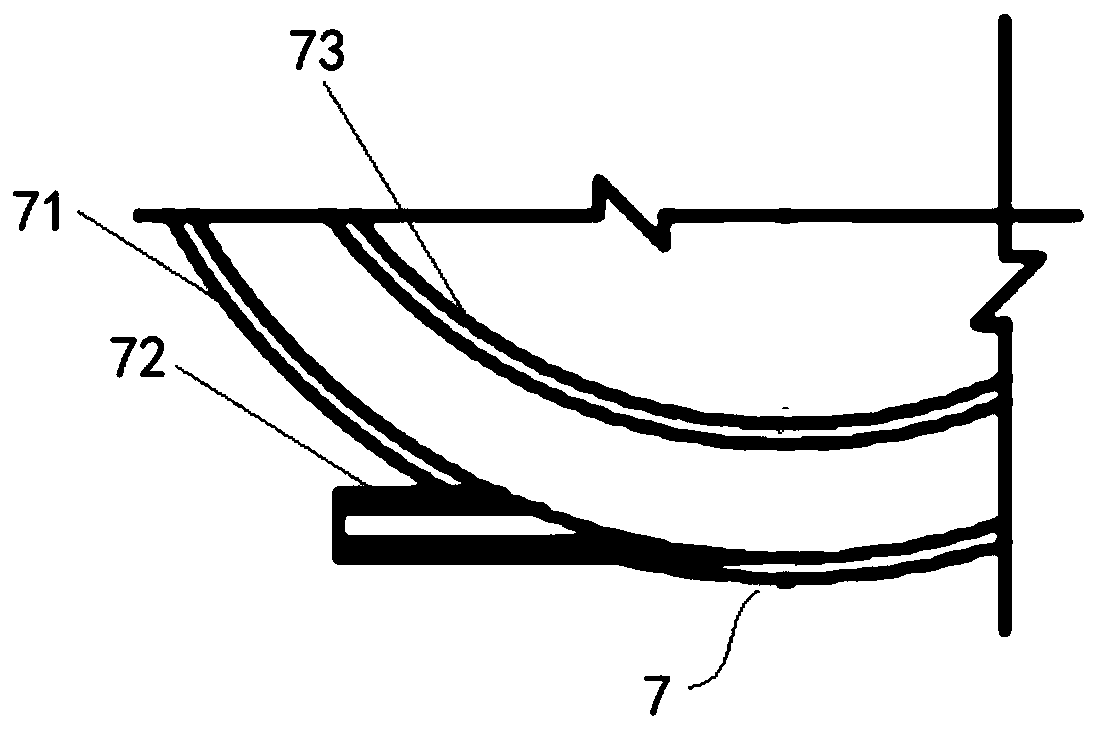

[0103] A multi-burner top-mounted entrained-bed gasifier such as Figure 1-3As shown, it includes a shell 4 and a burner part, a gasification chamber 2, a cooling chamber and a slag water outlet 13 that are connected in sequence from top to bottom and are coaxially arranged; the burner part and the slag water outlet 13 are respectively located at The top and bottom ends of the housing 4, the gasification chamber 2 and the cooling chamber are respectively arranged in the housing 4; the burner part includes a burner seat 1 and a burner combination; the burner The nozzle base 1 is arranged on the top of the gasification chamber 2; the burner assembly includes an eternal light burner 17 and six pulverized coal process burners 18; the eternal light burner 17 is arranged at the center of the burner seat 1 , used for ignition; the 6 pulverized coal process burners 18 are evenly dispersed on the burner seat 1 and arranged around the periphery of the lamp burner 17 for feeding; the bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com