Mechanical spraying construction process for light plastering gypsum

A technology of plastering plaster and mechanical spraying, which is applied in covering/lining, construction, building construction, etc. It can solve the problems of excessive technical requirements, harsh requirements for finished product maintenance, and insufficient perfection, so as to achieve more spraying areas and save manpower The effect of material cost and labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The applicant adopted a new type of material "light plastering gypsum" in the Chengdu Changxin Real Estate Wanhe Center, Chengdu Shangpu Hechuang Real Estate Tianlang Plaza and other projects, and applied the mechanical technology of the present invention to this material. The special spraying construction technology, after being put into use, greatly reduces the problems of hollowing and cracking of the plastering layer, avoids the common quality problem of vertical cracks at the junction of walls of different materials, and reduces the economic cost, time cost and post-processing cost of the operation. Maintenance costs and difficulties, while achieving social benefits such as energy saving and environmental protection.

[0021] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

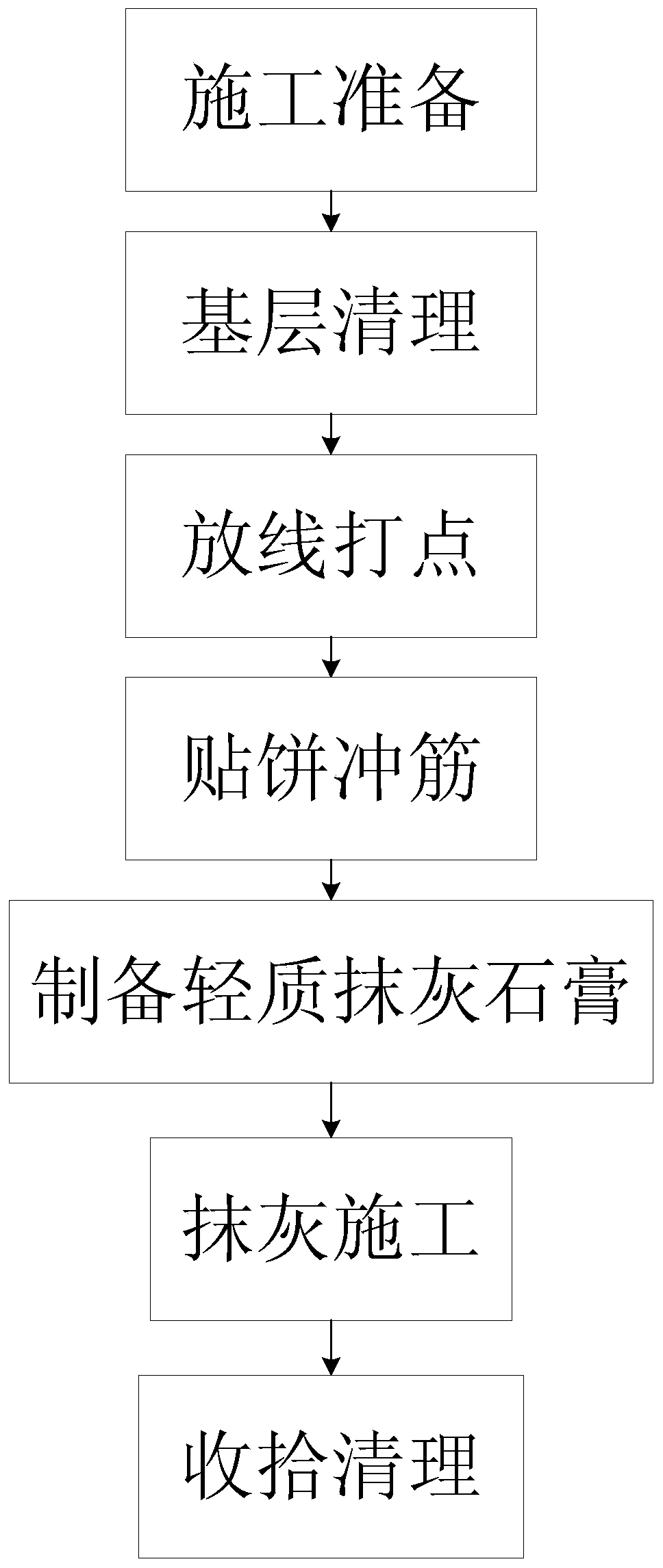

[0022] Such as figure 1 Shown, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com