Gel electrolyte and preparation method thereof, and sunlight-driven self-charging supercapacitor and self-charging method thereof

A gel electrolyte and supercapacitor technology, which is applied in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, hybrid capacitor electrolytes, etc., can solve the problem of increasing the complexity of the supercapacitor power supply system, manufacturing difficulty and economic cost, Hinder and restrict supercapacitor power supply system and other issues, to achieve the effects of easy industrial scale, easy access to raw materials, and considerable economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention provides a preparation method of the gel electrolyte described in the above technical solution, comprising the following steps:

[0054] mixing the metal salt with water to obtain an aqueous solution of the metal salt;

[0055] mixing the metal salt solution with montmorillonite to obtain a mixed dispersion;

[0056] Under the condition of heating, the mixed dispersion liquid and the high molecular polymer are mixed, and then the obtained mixed liquid is cooled to room temperature to obtain the gel electrolyte.

[0057] The present invention has no special requirements on the sources of the metal salt, montmorillonite and high molecular polymer, and commercially available products well known to those skilled in the art can be used. In the present invention, the heating temperature is preferably 60-80°C. In the present invention, the high molecular polymer is preferably slowly added to the mixed dispersion liquid for mixing; the high molecular pol...

Embodiment 1

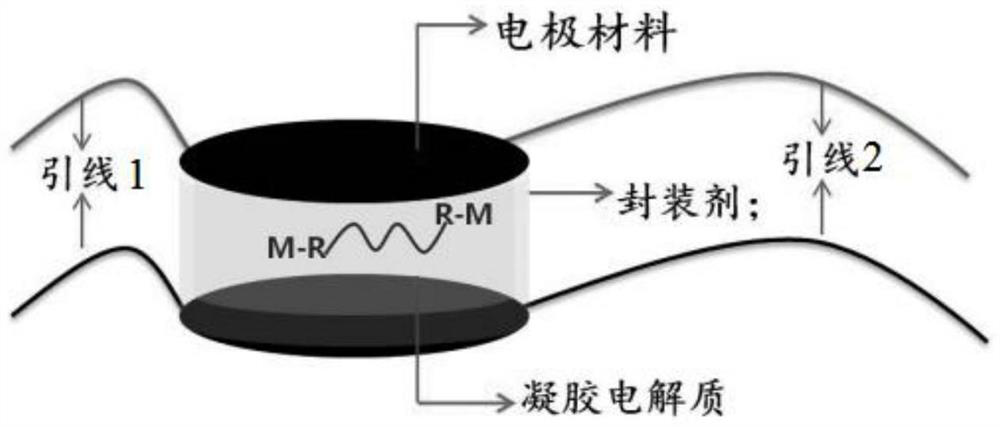

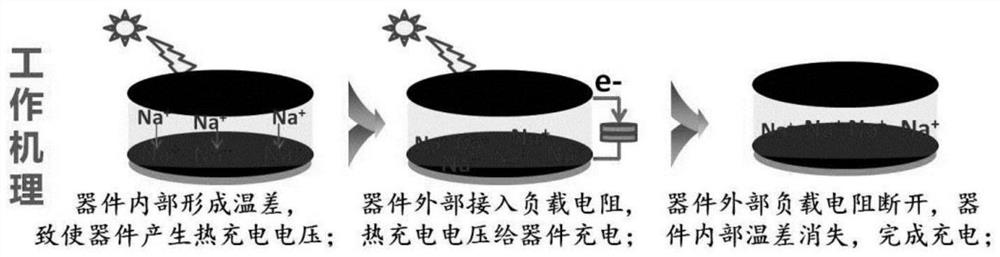

[0075] (1) Construction of solar-driven self-charging supercapacitor

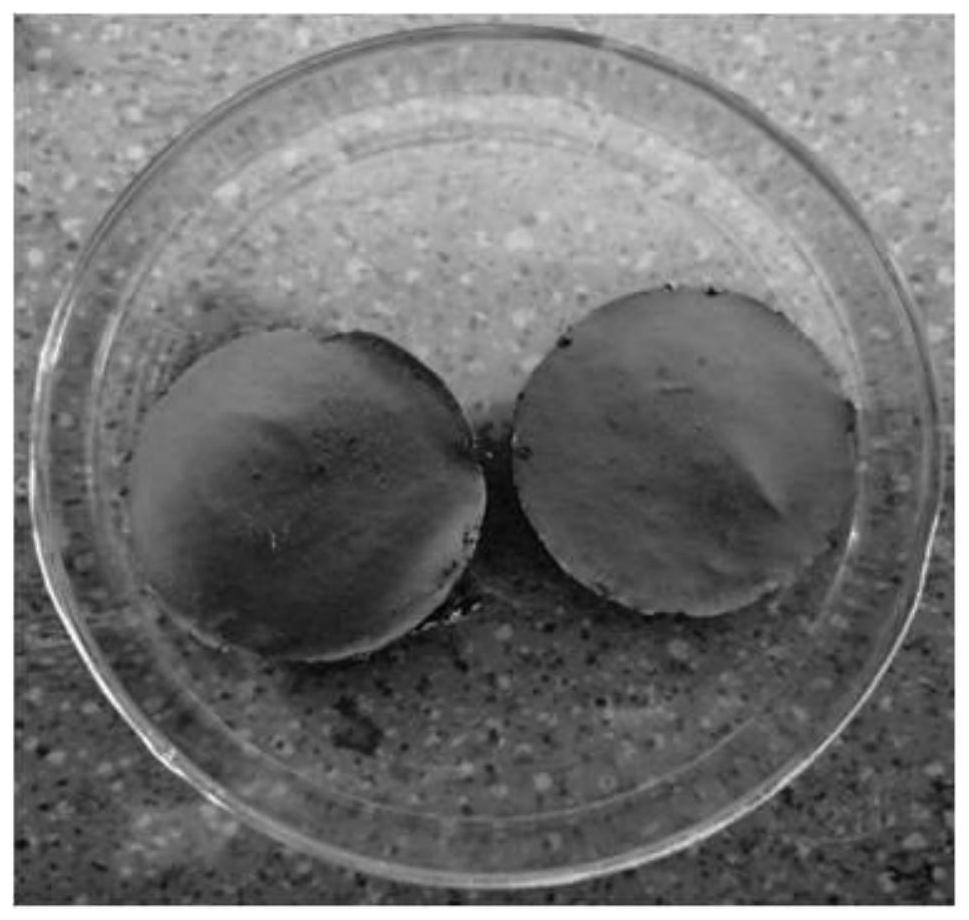

[0076] Preparation of light-to-heat conversion thin film electrodes: Mix graphene oxide and distilled water at a mass ratio of 1:5 to obtain a graphene oxide suspension; dilute the graphene oxide suspension to maintain a concentration of 5g / L, and dilute the graphite oxide Ultrasonic dispersion of olefin diluent for 5min, and then suction filtration of the diluent, the membranes after suction filtration were cleaned with distilled water and absolute ethanol, and dried at 60°C to obtain a circular graphene oxide membrane material. Obtain two circular graphene oxide thin film materials; Then utilize 50% HI solution to reduce two circular graphene oxide thin film materials, obtain two circular graphene thin film materials, such as image 3 shown. Graphene film materials exhibit high solar light absorption (such as Figure 4 Shown), the diameter of single circular graphene film material is 50mm, and thickness...

Embodiment 2

[0083] (1) Construction of solar-driven self-charging supercapacitor

[0084] Preparation of light-to-heat conversion film electrodes: carbon nanosheets, binder (polyvinylidene fluoride) and diluent (the volume ratio of ethanol and distilled water in the diluent is 1:5) according to the mass ratio of 2:0.5: After mixing at a ratio of 20, ball milling was carried out for 2 hours, and the solution after ball milling was ultrasonically dispersed for 5 minutes. Methods Two carbon nanosheet thin film electrodes with a thickness of 2.5 μm were obtained. Figure 11 is the solar reflection spectrum of the prepared carbon nanosheet thin film electrode material. It can be seen that the carbon nanosheet thin film electrode material exhibits good solar light absorption characteristics, and the solar energy absorption value of the carbon nanosheet thin film electrode is 0.90.

[0085] Preparation of gel electrolyte: Dissolve lithium chloride in water, add montmorillonite to lithium chlori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com