Assembling process and assembling production line for single-row roller bearings used in pairs

A technology for assembling production lines and roller bearings, used in bearings, bearing components, shafts and bearings, etc., can solve the problems of inability to meet the needs of industrial modernization, low production efficiency, low degree of automation, etc. The effect of small land area and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

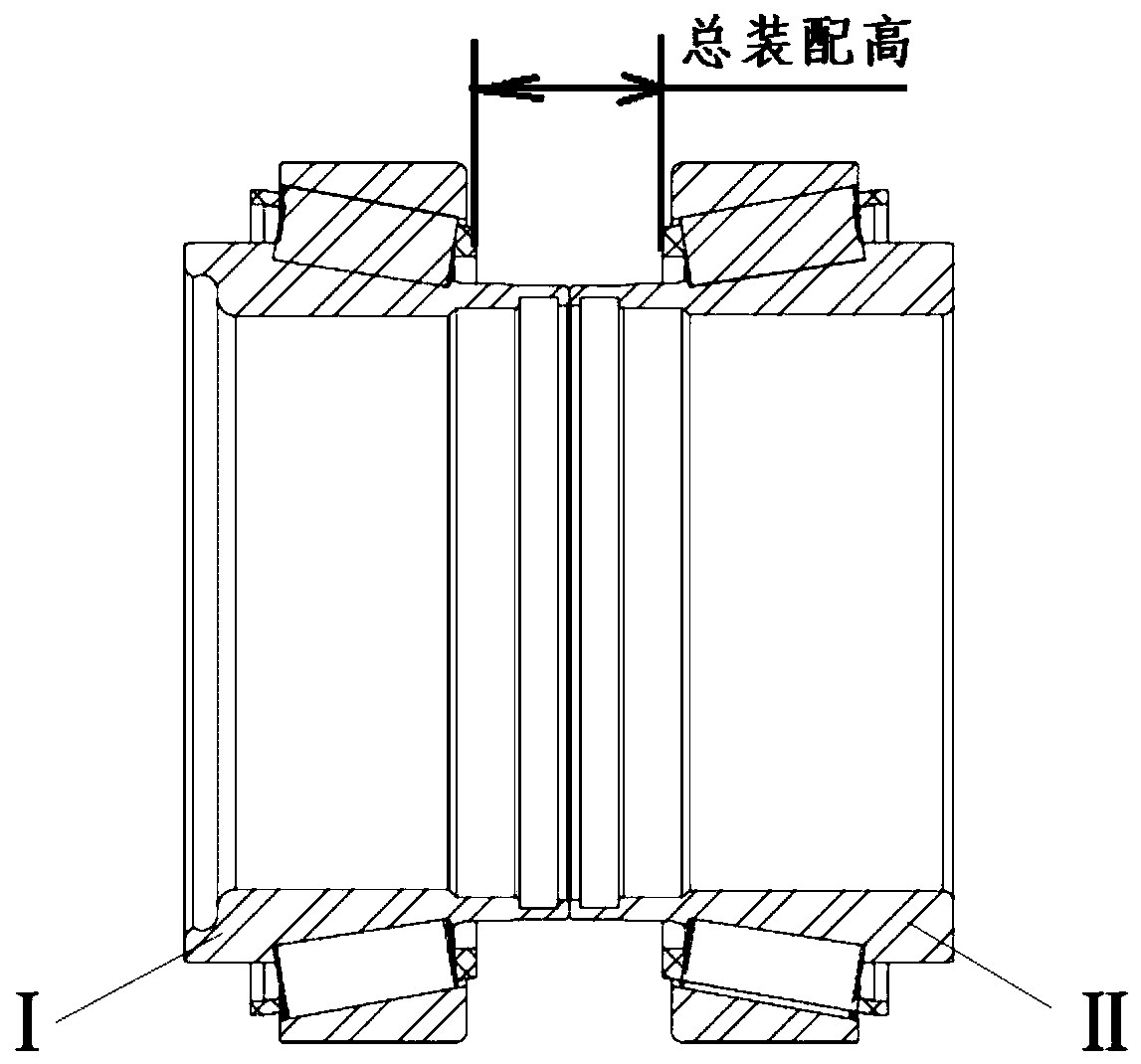

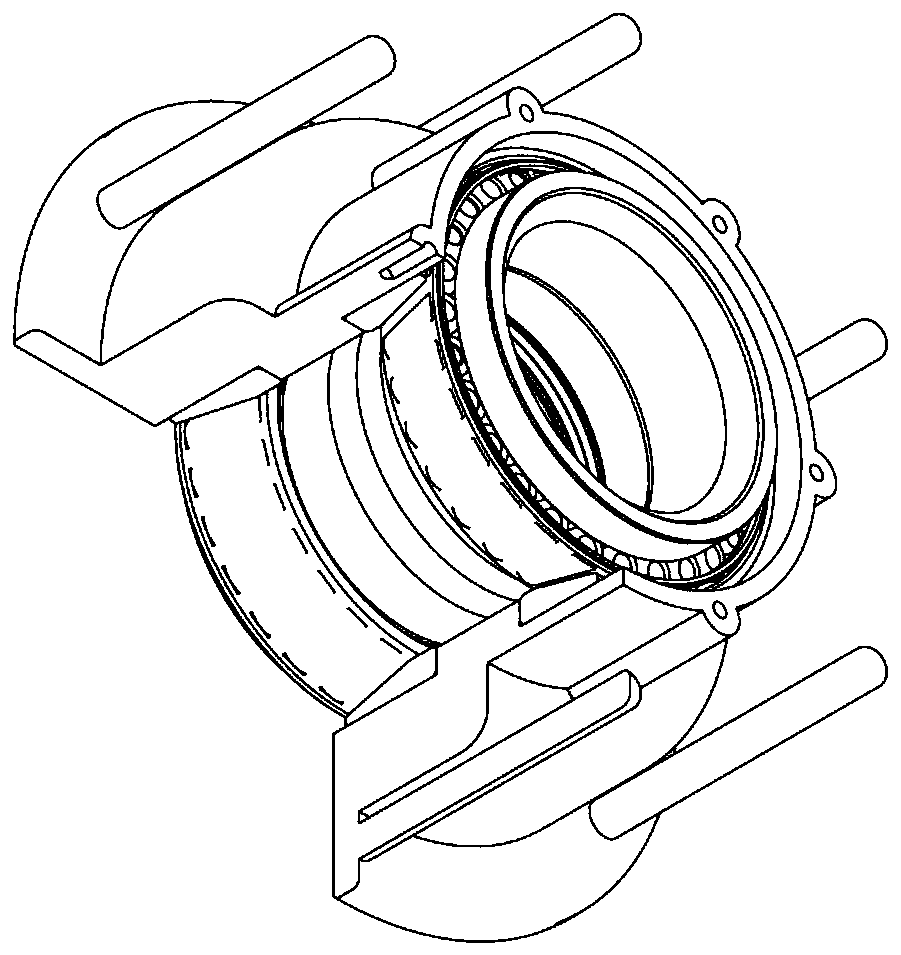

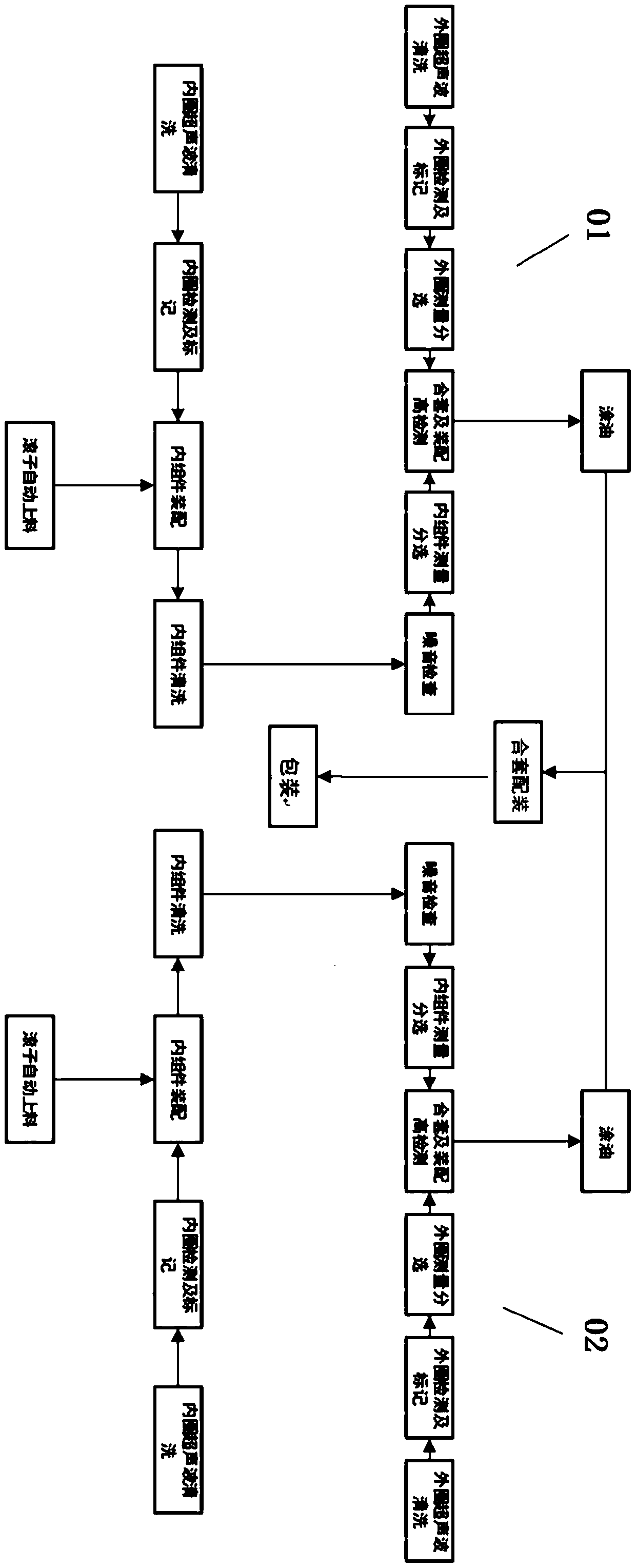

[0055] The invention firstly discloses an assembly process for single row roller bearings used in pairs, the assembly process is to clean, sort and test the parts that make up the bearing respectively; then the rollers are assembled to the cage, the cage and the inner ring The inner assembly is obtained by combining the inner assembly; the single row roller bearing is obtained after the inner assembly and the outer ring are assembled; a pair of single row roller bearings matching the bearings in the temporary storage warehouse and meeting the high tolerance requirements of the general assembly are output in pairs.

[0056] The concrete steps of this process are:

[0057] 11) The inner ring Ⅰ and inner ring Ⅱ are output after demagnetization, cleaning and drying;

[0058] 12) The output inner ring is detected and sorted by outer diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com