Liquid electrostatic safety testing device and method based on spraying process

An electrostatic safety and injection process technology, which is used in measuring devices, material analysis by electromagnetic means, instruments, etc., can solve the problems of leakage of liquid hydrocarbon mixed vapor, no report, explosion, etc., to achieve convenient maintenance, safe and reliable use, volume big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

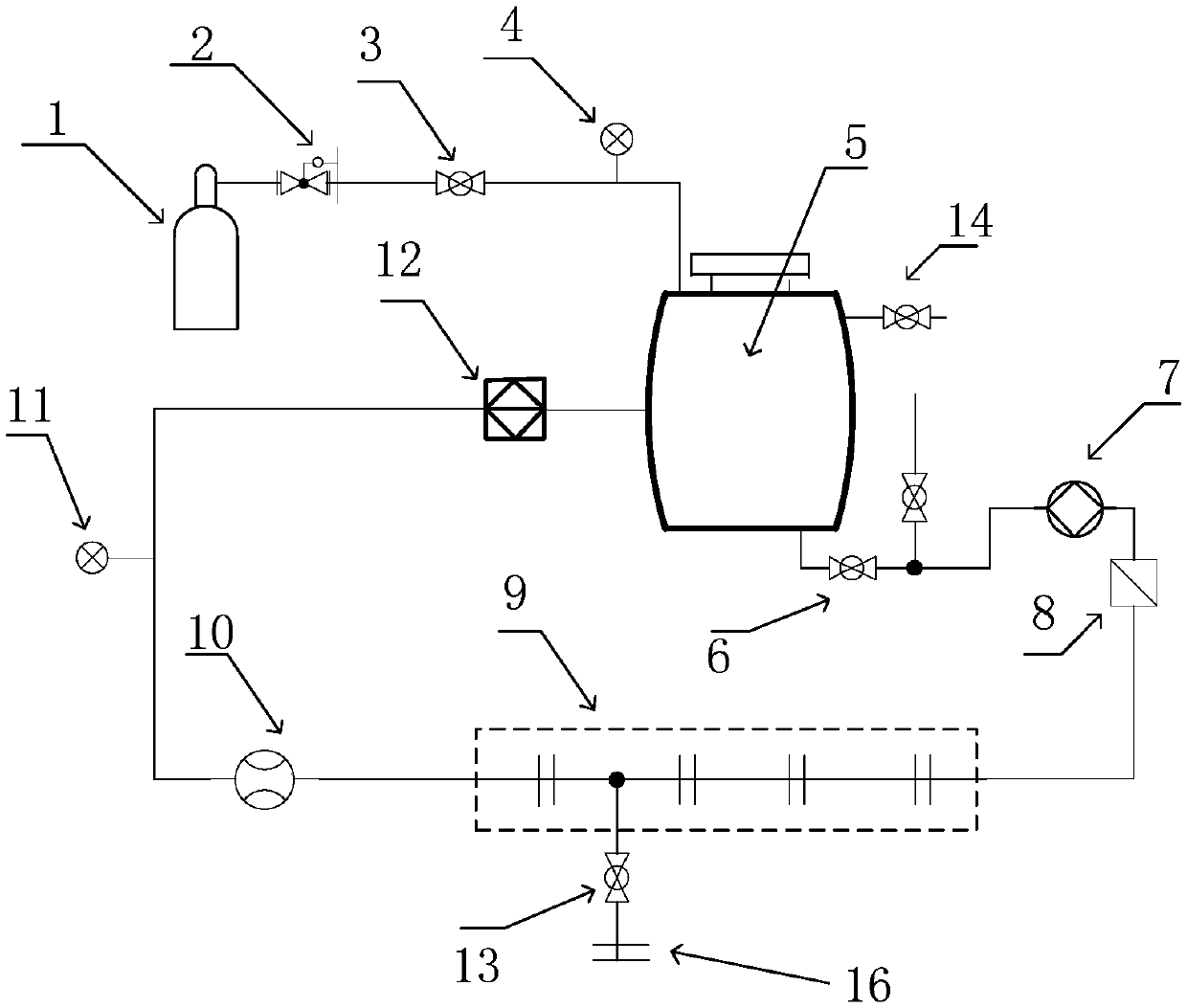

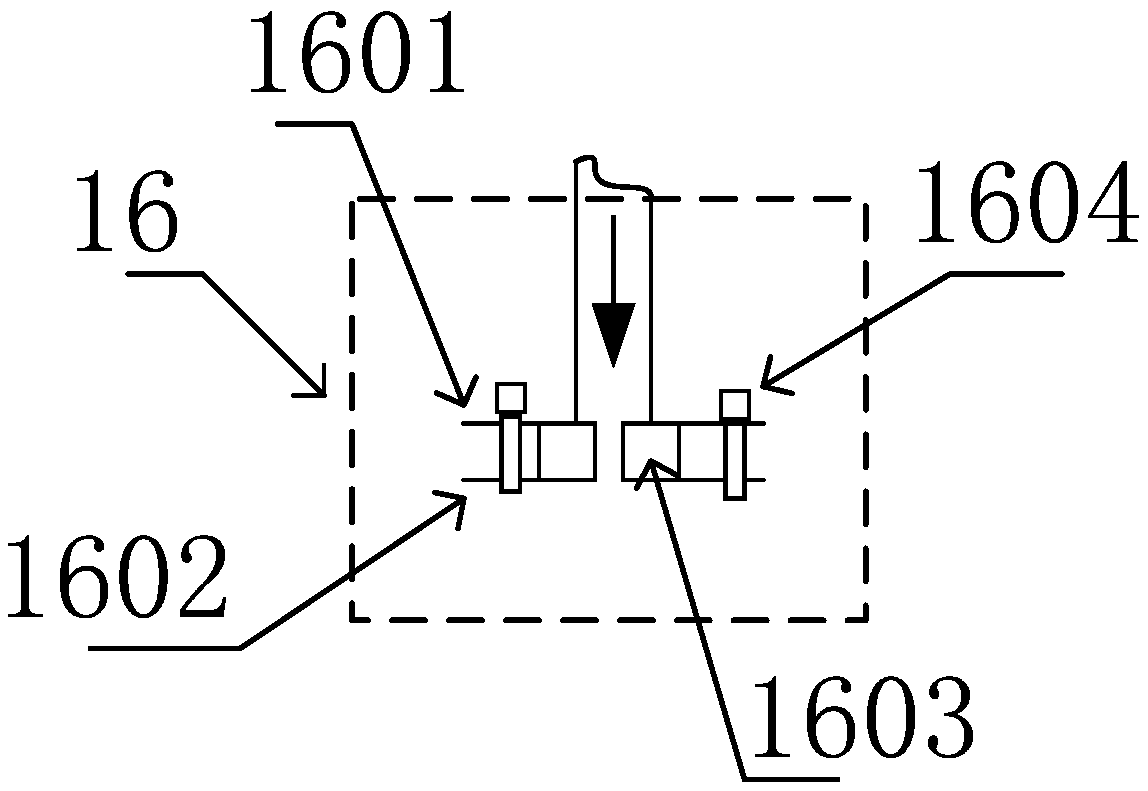

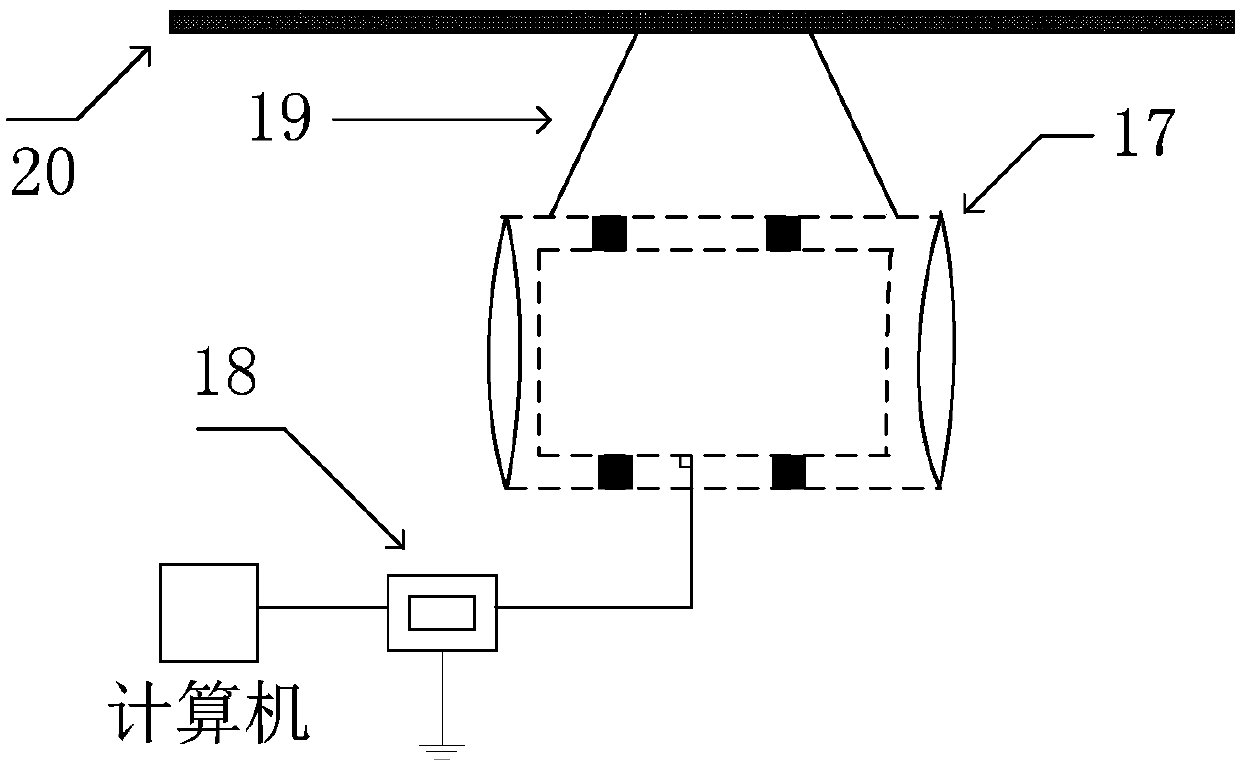

[0038] A liquid static electricity safety testing device based on a spraying process includes a test auxiliary platform, a liquid spraying simulation system and a liquid static electricity electrification measurement system.

[0039] Such as figure 1 As shown, the test auxiliary platform includes a high-pressure nitrogen cylinder 1, a pressure reducing valve 2, a first pressure gauge 4, a closed storage tank 5, an explosion-proof frequency conversion pump 7, a filter 8, a flow meter 10 and a second pressure gauge 11, and the high-pressure nitrogen cylinder 1. The pressure reducing valve 2, the first pressure gauge 4 and the airtight storage tank 5 are sequentially connected through a gas pipe, and a valve I3 is provided between the pressure reducing valve 2 and the airtight storage tank 5. The airtight storage tank 5, the explosion-proof frequency conversion pump 7, the filter 8, the flow meter 10 and the second pressure gauge 11 are sequentially connected through pipelines to...

Embodiment 2

[0051] On the basis of the above-mentioned embodiments, in addition, the present invention also discloses a liquid electrostatic safety testing method based on the spraying process, which is carried out according to the following steps:

[0052] Step 1: the liquid to be tested is contained in the airtight storage tank 5, and the airtight storage tank 5 is sealed by using a flange blind plate;

[0053] Step 2: Open the high-pressure nitrogen cylinder 1 and valve I3, adjust the pressure reducing valve 2 and control the pressure inside the airtight storage tank 5 according to the first pressure gauge 4;

[0054] Step 3: Open the valve II6 between the airtight storage tank 5 and the explosion-proof frequency conversion pump 7, close the valve III13 and valve IV14, and use the power provided by the explosion-proof frequency conversion pump 7 to realize the flow of liquid along the pipeline;

[0055] Step 4: remove impurities in the test liquid through a filter 8;

[0056] Step 5: ...

Embodiment 3

[0060] On the basis of the above-mentioned embodiment 1, in addition, the present invention also mentions a liquid electrostatic safety testing method based on the liquid splashing process, which adopts the above-mentioned liquid electrostatic safety testing device based on the liquid spraying process, as follows Steps to simulate the charging characteristics of oil splash in the storage tank:

[0061] Step 1: According to Embodiment 1, the top cover of the airtight storage tank 5 is transformed, and the top cover of the airtight storage tank 5 is opened, and the monitoring equipment for monitoring the electric field or liquid level potential in the airtight storage tank 5 is installed;

[0062] Step 2: repeat step 1-step 6 in embodiment 2;

[0063] Step 3: Use the explosion-proof frequency conversion pump 7 to adjust different flow rates, use the oil charge density meter 12 to record the charge density of the liquid entering the closed storage tank 5, and use the electric fie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com