Manufacturing method of enameled wire for network transformer

A technology for network transformers and manufacturing methods, applied in the direction of reducing the size of conductors/cables, used in heat treatment equipment, cable/conductor manufacturing, etc., can solve the problems of uneven paint coating on the surface of enameled wires, flexibility, thermal shock and thermal aging Poor performance and other problems, to achieve the effect of reducing the friction coefficient, good elongation, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for manufacturing an enameled wire for a network transformer, comprising the following steps:

[0044] A: Material selection: Copper rods with a diameter of 5mm are used as raw materials, and the copper rods are low-oxygen copper with a purity of more than 99.9%;

[0045] B: Drawing: First, the copper rod is drawn on a large wire drawing machine for multiple times of large stretching to obtain a 0.1mm wire rod, and then the wire rod is subjected to multiple large stretches through the fine wire drawing equipment to obtain a 0.05mm semi-finished wire rod ;

[0046] C: Cleaning: Clean the drawn semi-finished wire to remove the oil on the surface;

[0047] D: Annealing: use the non-contact annealing method to anneal the semi-finished wire twice in the annealing furnace, the temperature of the two annealing is 400 ° C and 340 ° C, and the inlet port of the annealing furnace is sealed by nitrogen sealing;

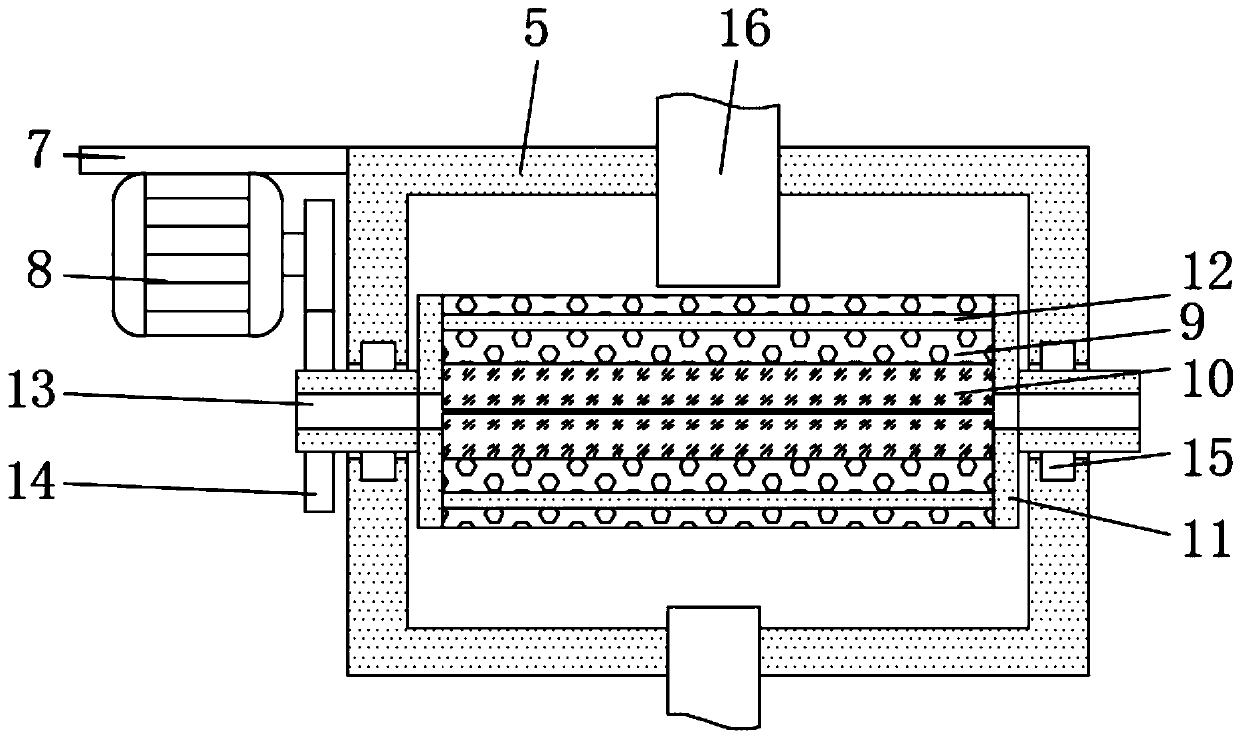

[0048] E: Painting: Use the painting device to paint the ...

Embodiment 2

[0054] A method for manufacturing an enameled wire for a network transformer, comprising the following steps:

[0055] A: Material selection: Copper rods with a diameter of 5mm are used as raw materials, and the copper rods are low-oxygen copper with a purity of more than 99.9%;

[0056] B: Drawing: First, the copper rod is drawn on a large wire drawing machine for multiple times of large stretching to obtain a 0.1mm wire rod, and then the wire rod is subjected to multiple large stretches through the fine wire drawing equipment to obtain a 0.05mm semi-finished wire rod ;

[0057] C: Cleaning: Clean the drawn semi-finished wire to remove the oil on the surface;

[0058] D: Annealing: use the non-contact annealing method to anneal the semi-finished wire twice in the annealing furnace, the temperature of the two annealing is 420 ℃ and 360 ℃, and the inlet port of the annealing furnace is sealed by nitrogen sealing;

[0059] E: Painting: Use the painting device to paint the semi-f...

Embodiment 3

[0065] A method for manufacturing an enameled wire for a network transformer, comprising the following steps:

[0066] A: Material selection: Copper rods with a diameter of 5mm are used as raw materials, and the copper rods are low-oxygen copper with a purity of more than 99.9%;

[0067] B: Drawing: First, the copper rod is drawn on a large wire drawing machine for multiple times of large stretching to obtain a 0.1mm wire rod, and then the wire rod is subjected to multiple large stretches through the fine wire drawing equipment to obtain a 0.05mm semi-finished wire rod ;

[0068] C: Cleaning: Clean the drawn semi-finished wire to remove the oil on the surface;

[0069] D: Annealing: use the non-contact annealing method to anneal the semi-finished wire twice in the annealing furnace, the temperature of the two annealing is 440 ℃ and 380 ℃, and the inlet of the annealing furnace is sealed by nitrogen sealing;

[0070] E: Painting: Use the painting device to paint the semi-fini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com