Permanent magnet synchronous motor starting and rotor position self-correcting method

A permanent magnet synchronous motor and rotor position technology, which is applied in the direction of controlling electromechanical transmission devices, electronic commutators, starting devices, etc., can solve the problems of high-frequency chattering, long time-consuming rotor positioning, etc., and eliminate the cumulative positioning deviation , shorten the positioning time, and realize the effect of zero speed and constant torque starting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

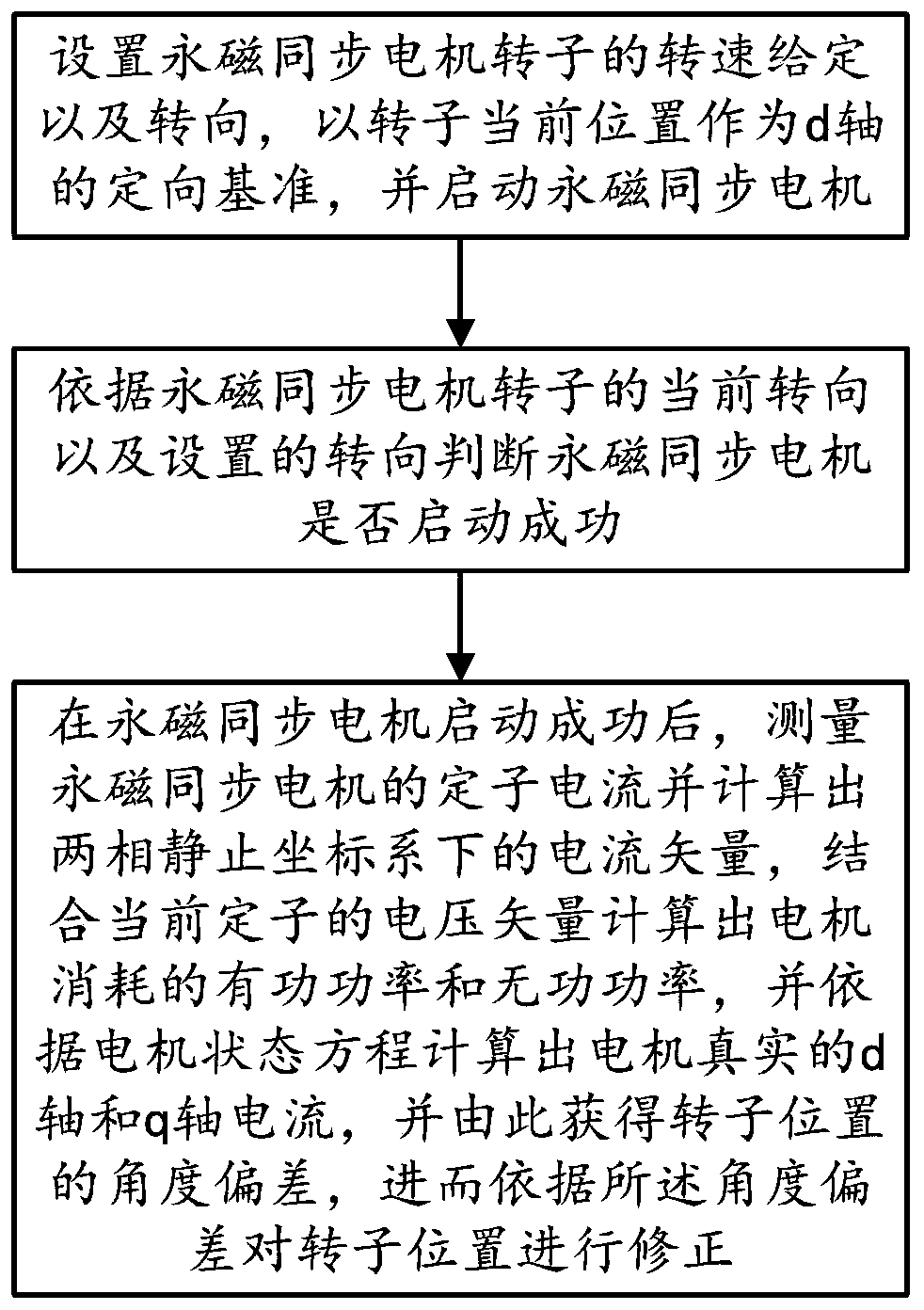

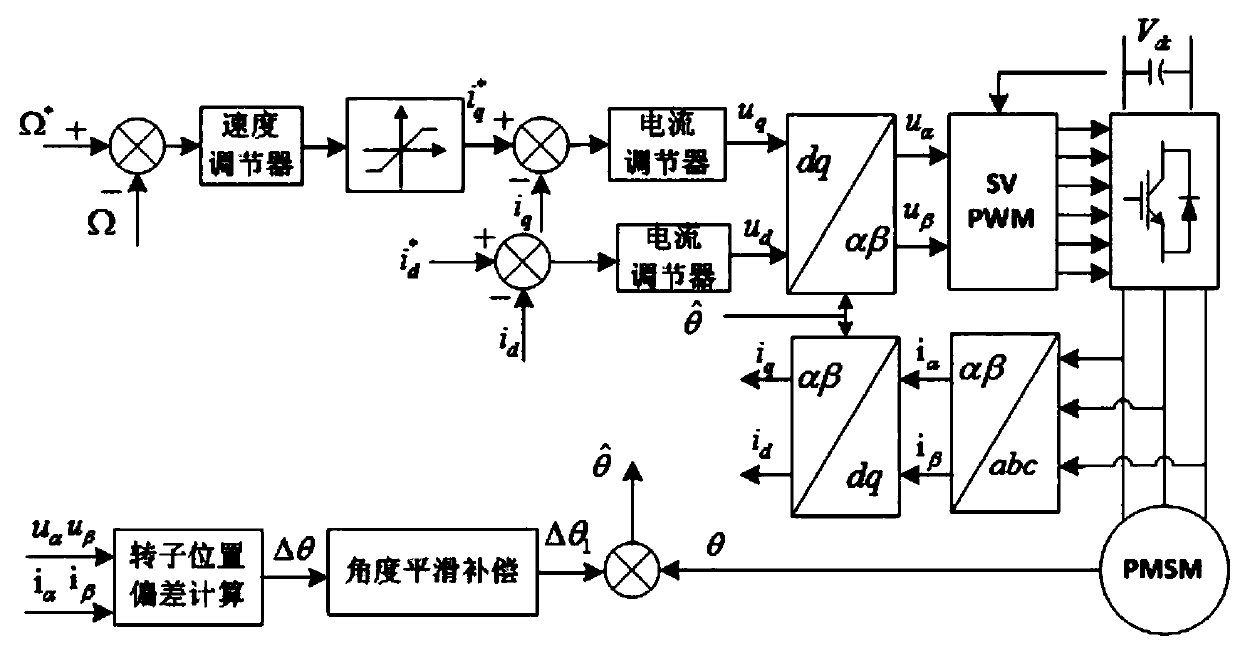

[0028] The general idea of the technical solution in the embodiment of the application is as follows:

[0029] When starting the permanent magnet synchronous motor, the current position of the rotor is used as the orientation reference of the d-axis to directly control the motor speed or torque, and at the same time measure the stator current of the permanent magnet synchronous motor and calculate the current vector in the two-phase stationary coordinate system , combined with the current stator voltage vector to calculate the active power and reactive power consumed by the motor; judge whether the motor starts successfully according to the current rotation of the rotor and the set rotation; calculate the real d-axis and q-axis current of the motor according to the motor state equation, And thereby obtain the angular deviation of the rotor position, and then perform linear or nonlinear smooth compensation on the rotor position according to the angular deviation.

[0030] Ple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com