Moisturizing facial mask liquid containing coconut oil, preparation method of moisturizing facial mask liquid containing coconut oil, and paster facial mask

A technology of coconut oil and wet face, applied in skin care preparations, pharmaceutical formulas, cosmetic preparations, etc., can solve the problem of unreasonable matching of types and dosages of moisturizers and emollient oils, poor stability of moisturizing masks, and emulsification Eliminate problems such as unreasonable agent system, achieve long-term moisturizing effect, realize large-scale industrial production, and achieve the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

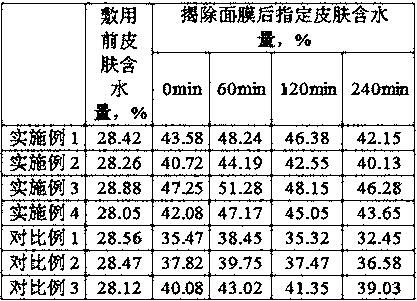

Examples

preparation example Construction

[0049] Second aspect, the present invention also provides the preparation method of above-mentioned moisturizing facial mask liquid, comprises the steps:

[0050] S1. Add water, humectant, and thickener into the emulsification pot, heat to dissolve, stir evenly, and keep warm to obtain phase A;

[0051] S2. Heat the coconut oil and emulsifier to dissolve, stir evenly to obtain phase B;

[0052] S3. Pump the phase B into the above-mentioned emulsification pot, keep warm, homogenize, and stir evenly; then cool down, add skin conditioner, preservative, pH regulator, essence, stir evenly, and filter to obtain.

[0053] Further, the heating temperature in step S1 is 80-85°C;

[0054] The heating temperature described in step S2 is 80-85°C;

[0055] In step S3, keep the temperature of the emulsification pot at 80-85°C; the homogenization time is 5-10min;

[0056] The temperature is lowered to below 45°C as described in step S3.

[0057] In the third aspect, the present invention...

Embodiment 1

[0063] A moisturizing facial mask containing coconut oil, oil-in-water type, which is prepared from the following components in weight percentage: humectant 9%, emulsifier 1.8%, coconut oil 2%, skin conditioner 1.1%, antiseptic 0.8% of agent, 0.1% of thickener, 0.1% of pH adjuster, 0.08% of essence, and the balance of water.

[0064] Wherein, the moisturizing agent is composed of the following raw materials by weight percentage: 3% sodium hyaluronate, 50% glycerin, 25% dipropylene glycol, 12% polyglycerol-10, 5% panthenol, and 5% trehalose.

[0065] The emulsifier is composed of the following raw materials by weight percentage: 50% of methyl glucose sesquistearate, 50% of PEG-20 methyl glucose sesquistearate.

[0066] The skin conditioning agent is composed of the following raw materials by weight percentage: Dipotassium Glycyrrhizinate 25%, Centella Asiatica Extract 18%, Polygonum cuspidatum Root Extract 10%, Scutellaria Baicalensis Root Extract 10%, Tea Extract 10%, Guangguo...

Embodiment 2

[0074] A moisturizing mask liquid containing coconut oil, oil-in-water type, which is prepared from the following components in weight percentage: humectant 4.5%, emulsifier 0.5%, coconut oil 0.5%, skin conditioner 0.1%, antiseptic 0.1% of agent, 0.05% of thickener, 0.01% of pH adjuster, 0.01% of essence, and the balance of water.

[0075] Wherein, the moisturizing agent is composed of the following raw materials by weight percentage: 0.1% sodium hyaluronate, 50% glycerin, 34% dipropylene glycol, 15% polyglycerol-10, 0.8% panthenol, and 0.1% trehalose.

[0076] The emulsifier is composed of the following raw materials by weight percentage: 25% of methyl glucose sesquistearate, 75% of PEG-20 methyl glucose sesquistearate.

[0077] The skin conditioning agent is composed of the following raw materials by weight percentage: 5% dipotassium glycyrrhizinate, 1% Centella Asiatica extract, 1% Polygonum cuspidatum root extract, 32% Scutellaria baicalensis root extract, 30% tea leaf ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com