Titanium dioxide particles with quick-acting and long-acting photocatalysis and preparation method thereof

A titanium dioxide and photocatalyst technology, applied in the field of titanium dioxide particles composed of quick-acting and long-acting and its preparation, can solve the problems of inability to continuously degrade for a long time, decrease in degradation efficiency, and inability to degrade rapidly, and achieve long shelf life and strong degradation activity. , the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

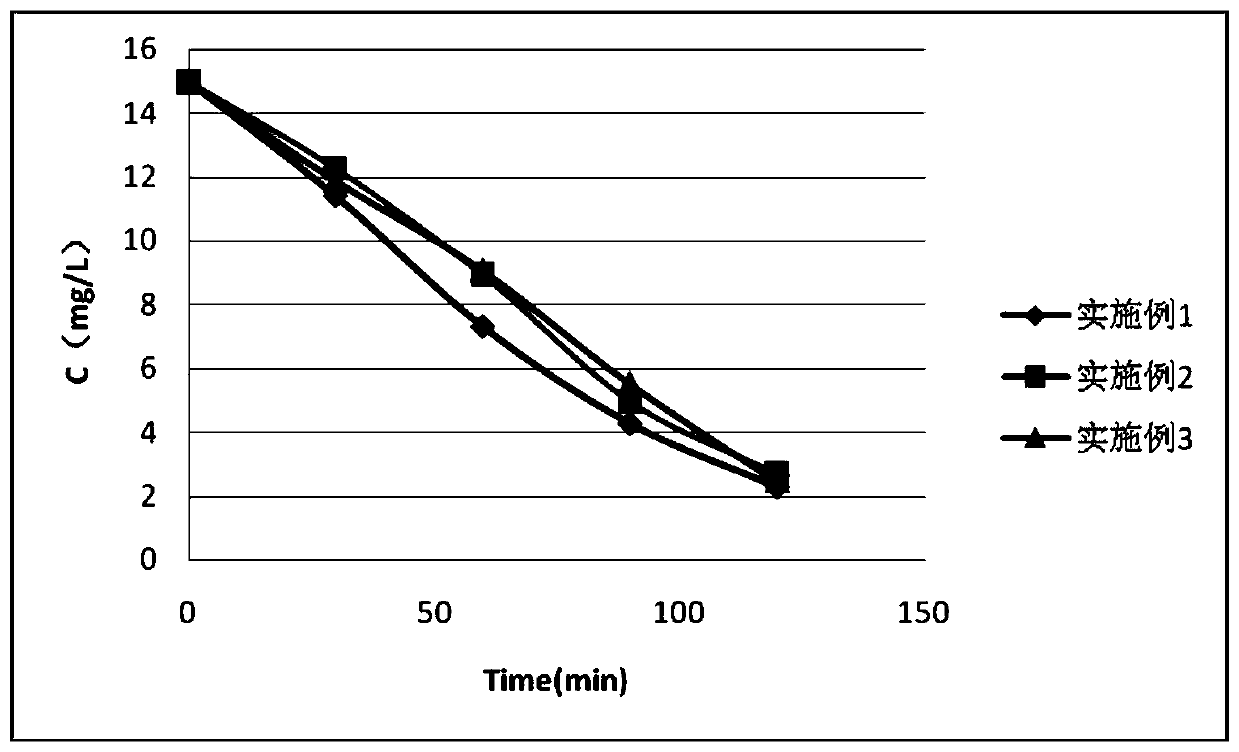

Embodiment 1

[0027] Embodiment 1: A kind of preparation method containing titanium dioxide photocatalyst

[0028] (1) Preparation of fast-acting titanium dioxide composite particles:

[0029] a. Take 10 g of chitosan and 15 g of potassium permanganate and place them in a universal pulverizer respectively, and pulverize them into powders with a particle size of 20 to 60 μm for later use;

[0030] b. Take 7g of sodium carboxymethyl cellulose and place it in a suitable container, first add purified water, stir to disperse and dissolve at a controlled temperature of 45°C, the stirring speed is 70r / min, the stirring time is 2.5h, and then continue Stirring conditions are, add absolute ethanol to obtain sodium carboxymethyl cellulose solution, and set aside; the mass ratio of the sodium hydroxymethyl cellulose to purified water is 1:25, and the volume ratio of the purified water to absolute ethanol 1:1;

[0031] c. get the nanoscale titanium dioxide 45g of chitosan after pulverization, formula...

Embodiment 2

[0038] Embodiment 2 A kind of preparation method containing titanium dioxide photocatalyst

[0039] (1) Preparation of fast-acting titanium dioxide composite particles:

[0040] a. Take 10 g of chitosan and 10 g of potassium permanganate and place them in a universal pulverizer respectively, and pulverize them into powders with a particle size of 20 to 60 μm for later use;

[0041] b. Put 5g of sodium carboxymethyl cellulose in a suitable container, first add purified water, stir to disperse and dissolve at a controlled temperature of 40°C, the stirring speed is 60r / min, the stirring time is 2h, and then continue to stir The conditions are, adding absolute ethanol to obtain sodium carboxymethyl cellulose solution, for subsequent use; the mass ratio of the sodium hydroxymethyl cellulose to purified water is 1:20, and the volume ratio of the purified water to absolute ethanol is 1:1;

[0042] c. get the nanoscale titanium dioxide 40g of chitosan after pulverization, formula qu...

Embodiment 3

[0049] Embodiment 3: A kind of preparation method containing titanium dioxide photocatalyst

[0050] (1) Preparation of fast-acting titanium dioxide composite particles:

[0051] a. Take 10g of chitosan and 30g of potassium permanganate and place them in a universal pulverizer respectively, and pulverize them into powders with a particle size of 20-60 μm, and set aside;

[0052] b. Put 8g of sodium carboxymethyl cellulose in a suitable container, first add purified water, stir to disperse and dissolve at a controlled temperature of 50°C, the stirring speed is 80r / min, the stirring time is 3h, and then continue to stir The conditions are, adding absolute ethanol to obtain sodium carboxymethyl cellulose solution, for subsequent use; the mass ratio of the sodium hydroxymethyl cellulose to purified water is 1:30, and the volume ratio of the purified water to absolute ethanol is 1:1;

[0053] c. get the nano-scale titanium dioxide 60g of chitosan after pulverization, formula quan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com