Knife handle with built-in vibration sensor

A technology of vibration sensor and tool handle, applied in the direction of positioning device, clamping, support, etc., can solve the problem of long vibration signal propagation path, and achieve the effect of reducing processing difficulty, long life and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

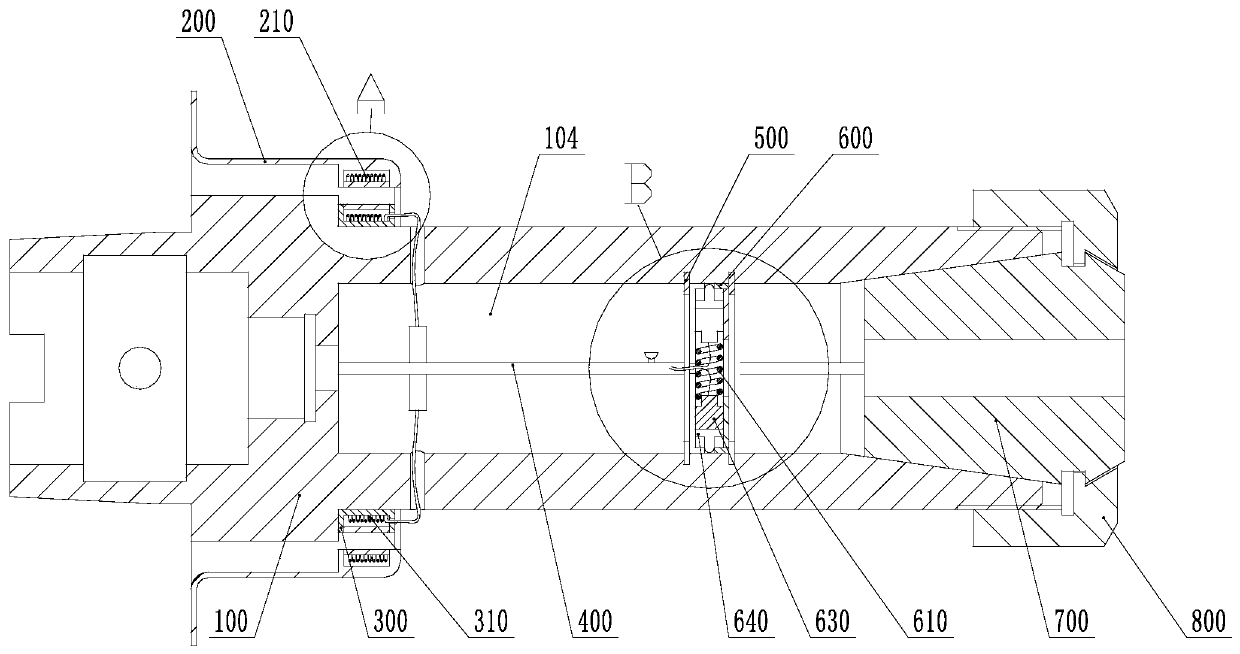

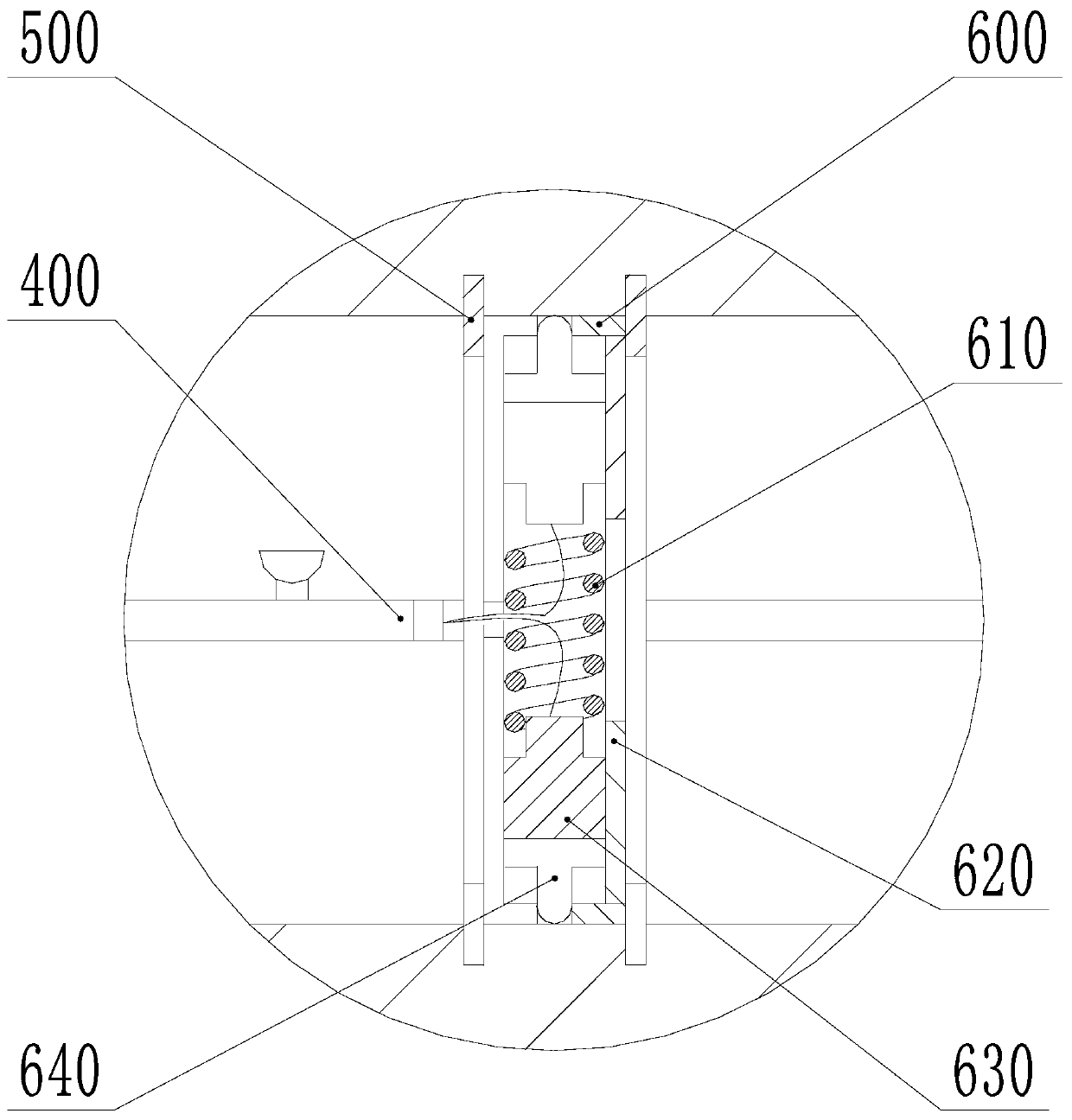

[0031] In this embodiment, a tool handle with a built-in vibration sensor, such as figure 1 As shown, it includes a tool handle main body 100, a data acquisition circuit board 400, a vibration acquisition component, an electric energy receiving component and an electric energy sending component. The middle part of the tool handle main body is provided with an inner hole 104, and the data acquisition circuit board and the vibration acquisition component are installed in the inner hole. Among them, the power receiving component is arranged on the outer surface of the handle main body, the power sending component is installed coaxially with the tool handle main body, the power sending component and the power receiving component are arranged facing each other with a gap left, and the power sending component and the power receiving component conduct wireless energy Transmits and supplies power to the data acquisition board. Among them, the power receiving component and the power se...

Embodiment 2

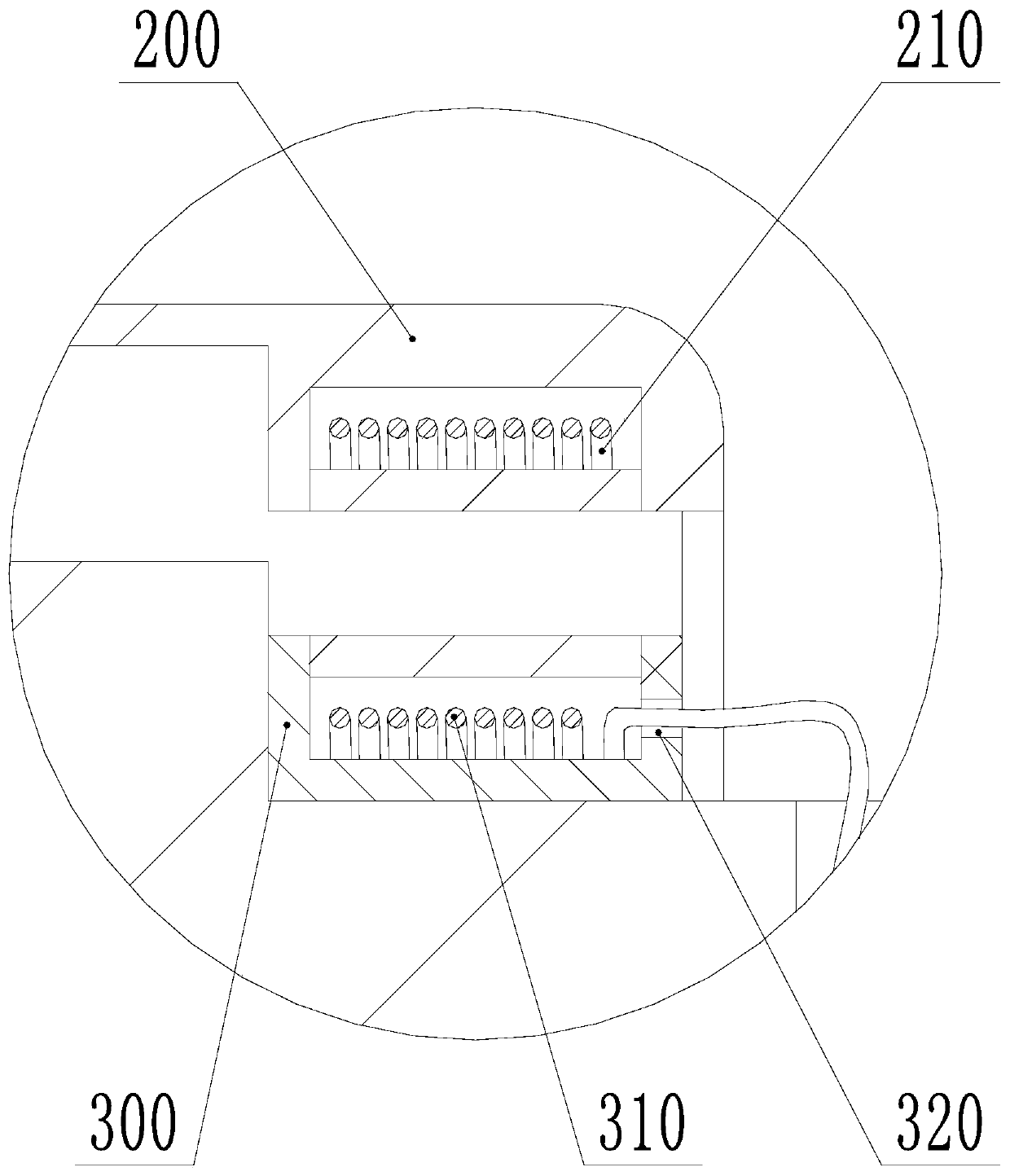

[0040] This embodiment is a tool holder with a built-in vibration sensor. The difference between this embodiment and Embodiment 1 is that, as Figure 9 As shown, the power sending assembly also includes a signal receiving coil 211, the signal receiving coil is arranged in the second casing, the power receiving assembly also includes a signal sending coil 311, the signal sending coil is arranged in the third casing, and the signal receiving coil is facing Signal sending coil. The vibration signal stored in the data acquisition circuit board can be wirelessly transmitted through the signal receiving coil and the signal sending coil, which is convenient for operation and use.

[0041] When in use, in addition to obtaining vibration data by means of a data storage card, data can also be obtained by means of wireless transmission. Such as Figure 9 As shown, a signal receiving coil 211 is added to the power sending component, and a signal sending coil 311 is added to the power re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com