Wide polytetrafluoroethylene turning film ironing and slitting equipment and machining method

A technology of polytetrafluoroethylene and processing methods, which is applied in the field of mechanical equipment, can solve the problems of easy curling of kelp edges, etc., and achieve the effects of stable product quality, reduced production man-hours, and neat edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

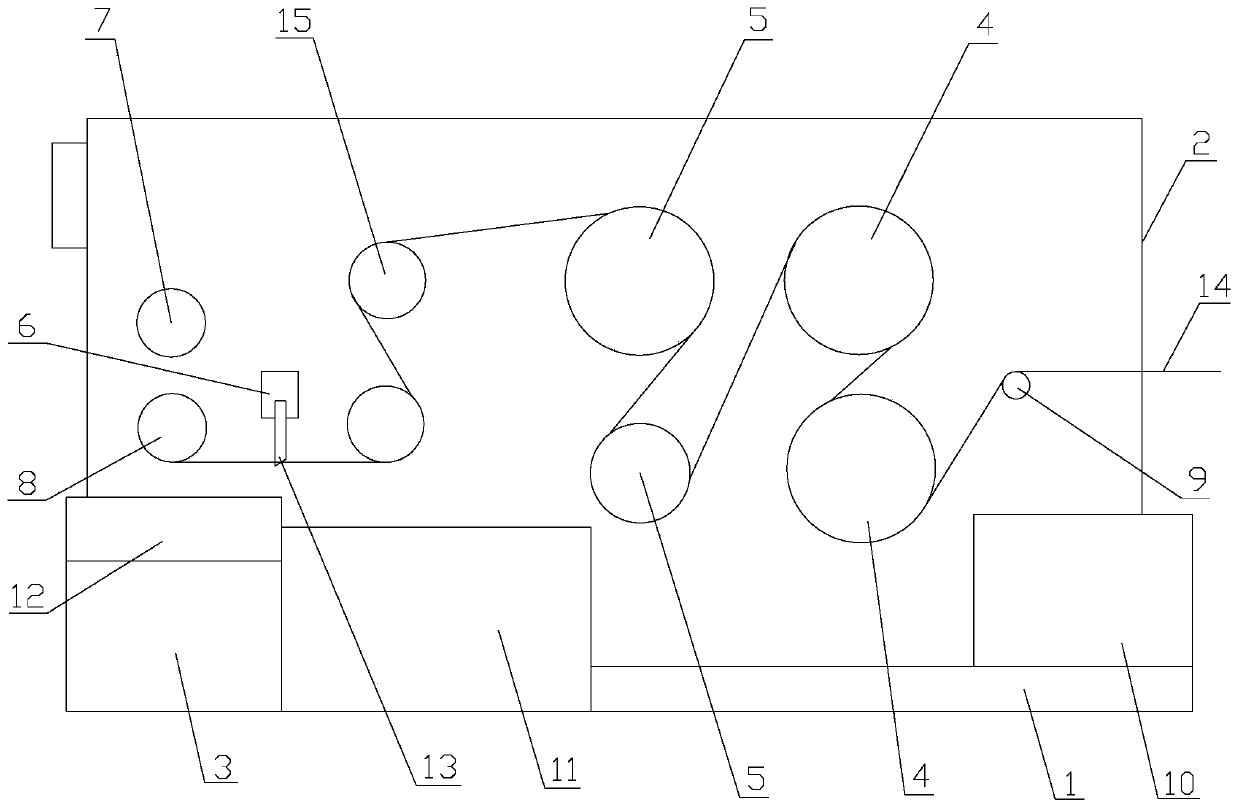

[0025] Such as figure 1 As shown, a wide-width polytetrafluoroethylene turning film ironing and cutting equipment includes a base 1, a support 2, a control cabinet 3, a heating roller 4, a cooling roller 5, a cutting shaft 6, a winding roller and a plurality of guides Roller, the support 2 is connected and fixed to the base 1, the side of the support 2 is provided with a control cabinet 3; and fixed, the inside of the control cabinet 3 is provided with a controller, and a control panel 12 is provided on the top of the control cabinet 3; during the working process of the device, the turning film 14 is introduced into the heating roller 4 through the first guide roller 9 for ironing, and then cooled After the roller 5 is cooled, it is led to the winding roller by the second guide roller 15, and the front end of the winding roller is provided with a cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com