Visualization experiment method for dynamically simulating shale pressing fracture network

An experimental method and dynamic simulation technology, which is applied in earthwork drilling, wellbore/well components, buildings, etc., can solve the problems of failure to meet the quantitative requirements of fracture shape, optimization of fracturing scheme design and quantitative evaluation after fracturing, and accurate simulation results To solve problems such as poor performance, to achieve the effect of intuitive crack shape, uniform force, and stable loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

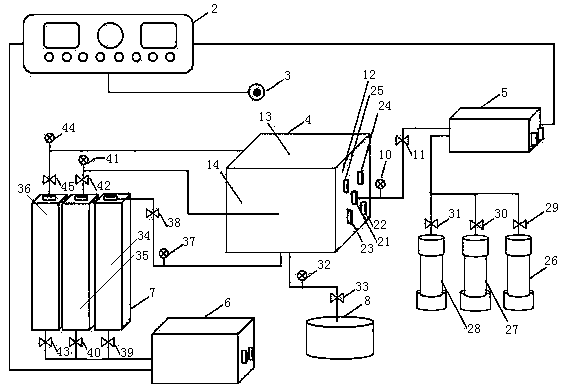

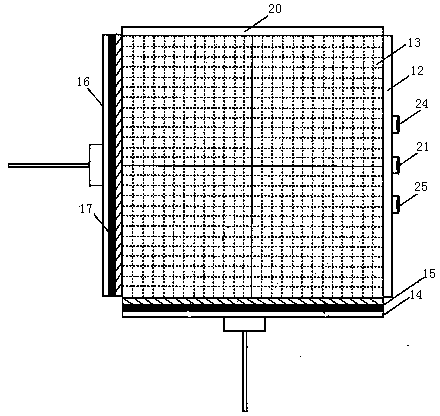

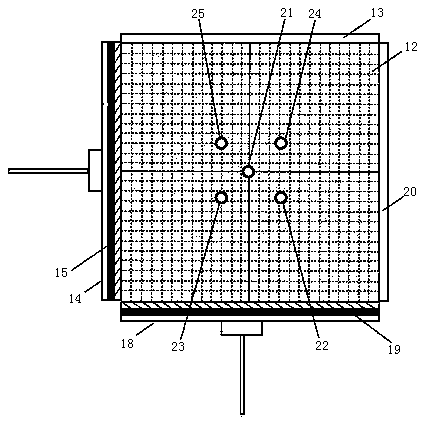

[0034] see figure 1 and Figure 4 , an experimental method for dynamically simulating shale fracturing fracture network visualization, comprising the following steps:

[0035] a. According to the reservoir mechanical parameters of the shale block to be simulated, high-strength photosensitive resin is selected as the raw material for 3D printing, and the translucent visual simulation shale rock sample 1 is printed first, and then the translucent visual simulation shale is printed The rock sample 1 is polished, and the open-hole wellbore is selected according to the five-point method in the visualized simulated shale rock sample 1, and the simulated wellbore 9 matching the open-hole wellbore is made of stainless steel;

[0036] b. Place the 3D printed visualized simulated shale rock sample 1 in the visualized fracturing cavity 4 of the visualized experimental device, and then put the simulated wellbore 9 into the open hole wellbore of the visualized simulated shale rock sample ...

Embodiment 2

[0041] see figure 1 and Figure 4 , an experimental method for dynamically simulating shale fracturing fracture network visualization, comprising the following steps:

[0042] a. According to the reservoir mechanical parameters of the shale block to be simulated, high-strength photosensitive resin is selected as the raw material for 3D printing, and the translucent visual simulation shale rock sample 1 is printed first, and then the translucent visual simulation shale is printed The rock sample 1 is polished, and the open-hole wellbore is selected according to the five-point method in the visualized simulated shale rock sample 1, and the simulated wellbore 9 matching the open-hole wellbore is made of stainless steel;

[0043] b. Place the 3D printed visualized simulated shale rock sample 1 in the visualized fracturing cavity 4 of the visualized experimental device, and then put the simulated wellbore 9 into the open hole wellbore of the visualized simulated shale rock sample ...

Embodiment 3

[0049] see Figure 1-Figure 4 , an experimental method for dynamically simulating shale fracturing fracture network visualization, comprising the following steps:

[0050] a. According to the reservoir mechanical parameters of the shale block to be simulated, high-strength photosensitive resin is selected as the raw material for 3D printing, and the translucent visual simulation shale rock sample 1 is printed first, and then the translucent visual simulation shale is printed The rock sample 1 is polished, and the open-hole wellbore is selected according to the five-point method in the visualized simulated shale rock sample 1, and the simulated wellbore 9 matching the open-hole wellbore is made of stainless steel;

[0051] b. Place the 3D printed visualized simulated shale rock sample 1 in the visualized fracturing cavity 4 of the visualized experimental device, and then put the simulated wellbore 9 into the open hole wellbore of the visualized simulated shale rock sample 1;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com