Comprehensive treatment box for waste incineration flue gas

A comprehensive treatment and waste incineration technology, applied in gas treatment, combustion product treatment, incinerator and other directions, can solve the problems of unsuitable small integration, large wind resistance of the system, and large land occupation, saving space, improving efficiency, The effect of reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

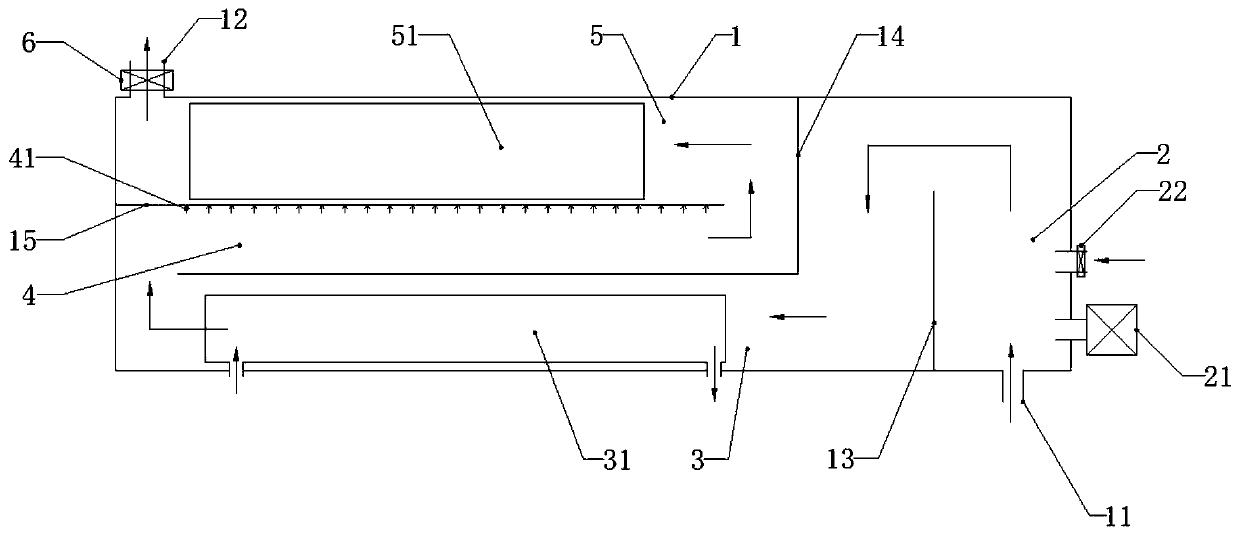

[0033] Such as figure 1 As shown, the present invention relates to a comprehensive treatment box for waste incineration flue gas, including a box body 1, and the box body 1 is separated into a secondary combustion chamber 2, a heat exchange area 3, a desulfurization and denitrification area 4 and a dust removal area connected in sequence by a partition Demister area 5, the box body 1 has a smoke inlet 11 and a smoke exhaust port 12, the second combustion chamber 2 communicates with the smoke inlet pipe through the smoke inlet 11, and the dust and mist removal area 5 passes through the The smoke outlet 12 communicates with the outside of the box body 1 .

[0034] As a further solution of this embodiment, the side wall of the second combustion chamber 2 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com