Stress resonance fatigue test method and test system for lightweight high-strength composite material

A technology for fatigue testing and composite materials, which is applied in the field of stress resonance fatigue test methods and test systems for lightweight high-strength composite materials, and can solve problems such as inability to meet the requirements of composite material resonance fatigue tests, research on resonance fatigue tests and analysis methods, and large differences , to achieve the effect of reducing the probability of failures and accidents, having great reference significance and increasing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

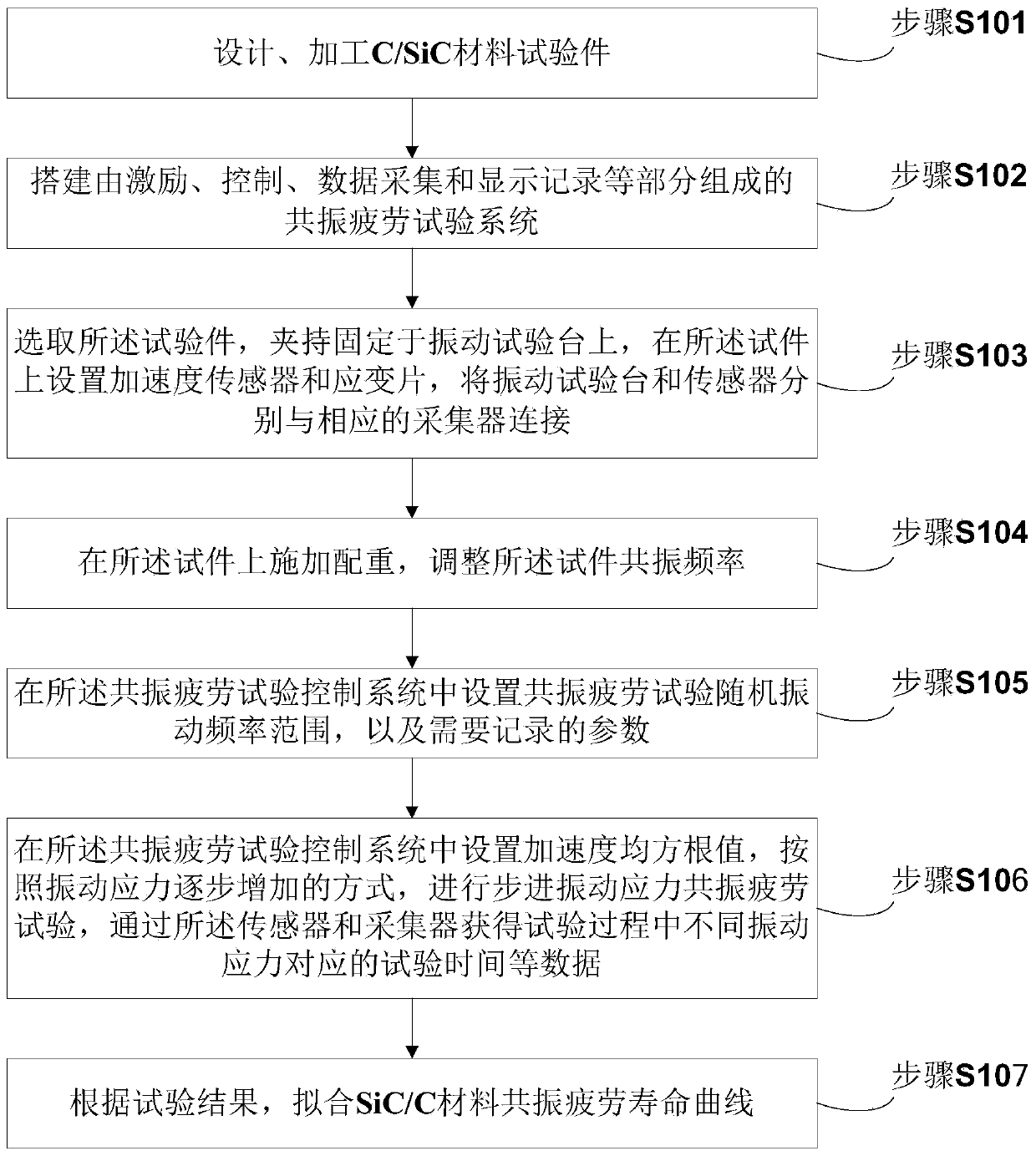

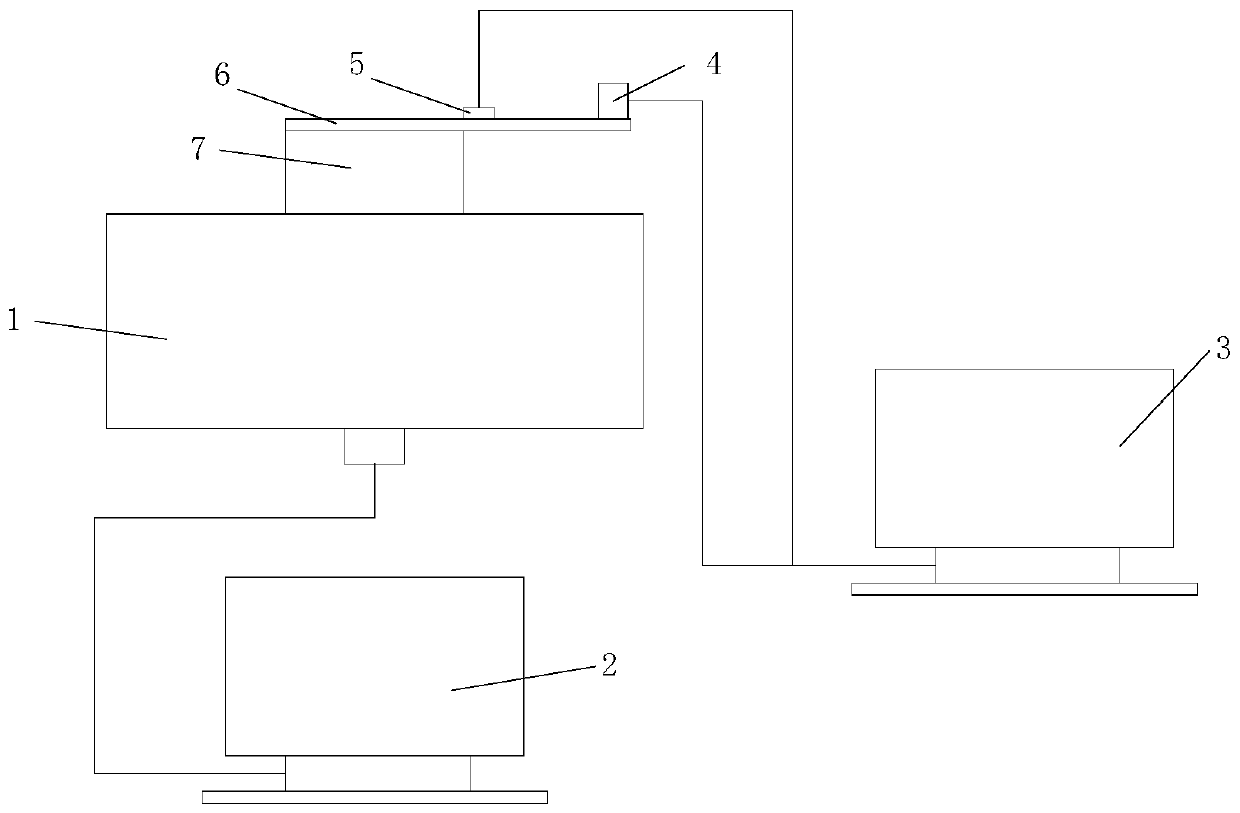

Method used

Image

Examples

Embodiment 1

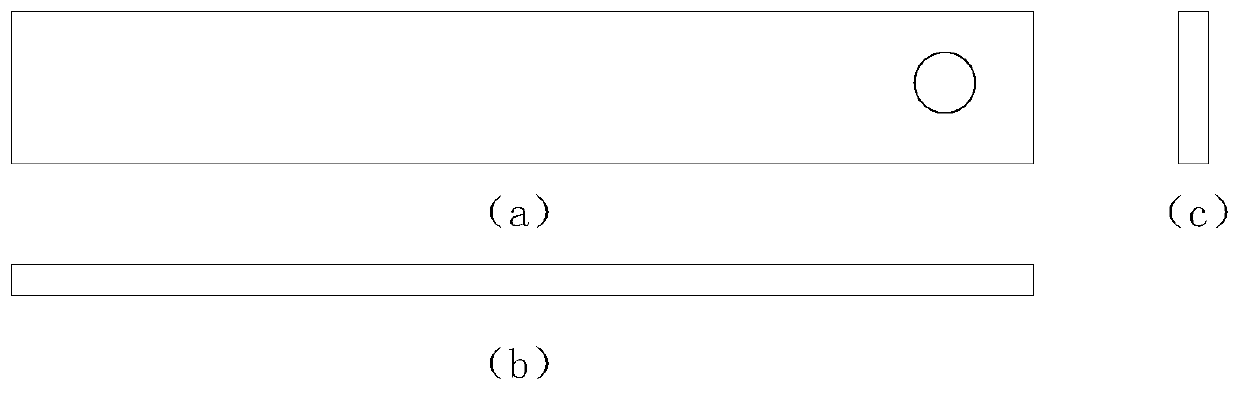

[0080] Select a cantilever beam structure test piece with a length of 25cm, a width of 25mm, and a thickness of 3mm. The number of test pieces is 30, which are divided into 5 groups, with 6 test pieces in each group.

[0081] The 6 test pieces of the first group are evenly distributed and fixed on the vibration test bench, the acceleration sensor is attached to the outermost end of each test piece, and the strain gauge is pasted at the clamped root of each test piece.

[0082] By applying a counterweight to the outer end of the test piece, the natural frequency f of the test piece 0 adjust to f a ±0.5Hz(f a The resonant frequency value concerned by this test is 11Hz), and then apply sine frequency sweep excitation, the frequency range is 5-100Hz, the amplitude is 0.1g, the sampling frequency is 2048Hz, and the adjusted natural frequency is recorded by the acceleration sensor, and the calculation is obtained. The mean value of the natural frequency of a group of test pieces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com