Steel size and quantity identification method based on deep learning, intelligent equipment and storage medium

A recognition method and deep learning technology, applied in the field of image vision, can solve problems such as photocell sensitivity reduction, steel occlusion, and traditional algorithms are not very practical, so as to reduce labor costs and time costs, and improve efficiency and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

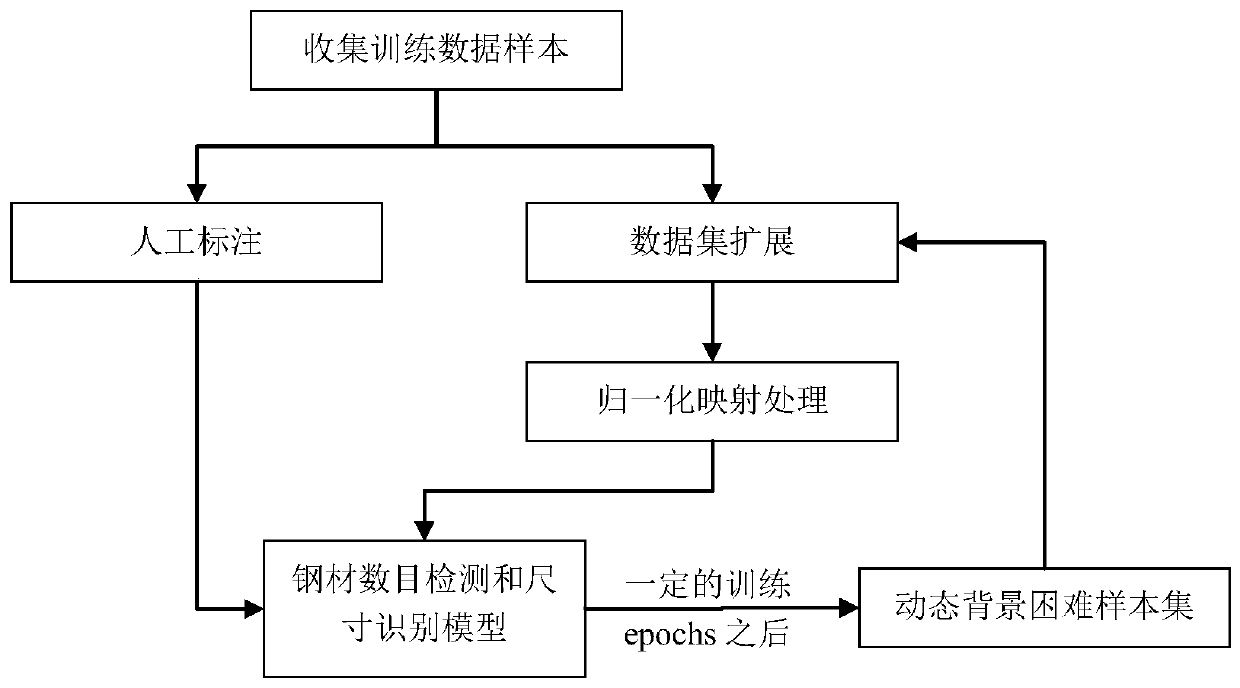

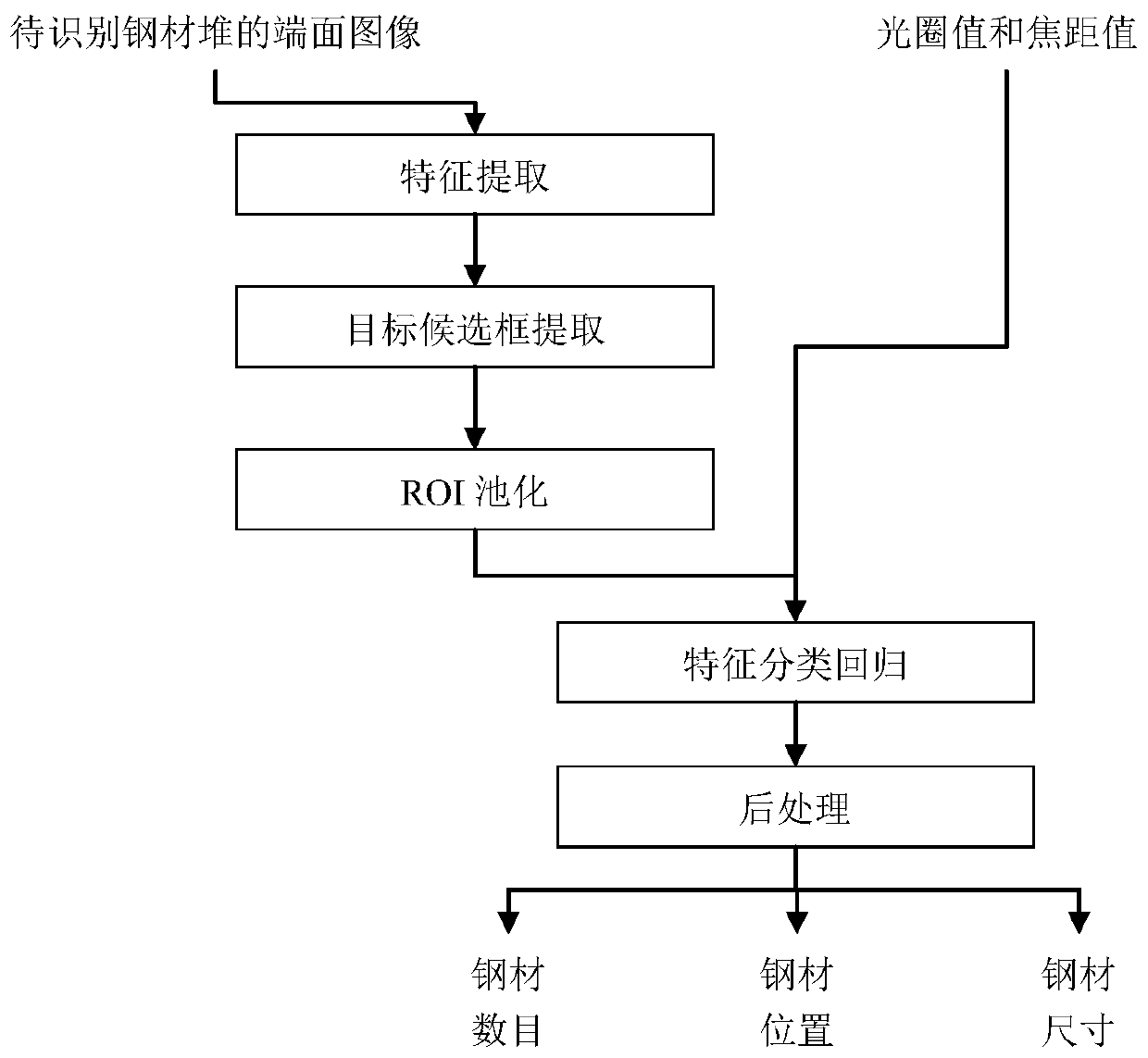

[0041] The identification method based on deep learning steel size and quantity provided in this embodiment includes the following steps:

[0042] Step S1, using the camera to capture multiple end face images of the steel stack, using the multiple end face images of the steel stack and the aperture value and focal length value of the camera corresponding to each end face image of the steel stack to train the steel number detection and size recognition neural network Model;

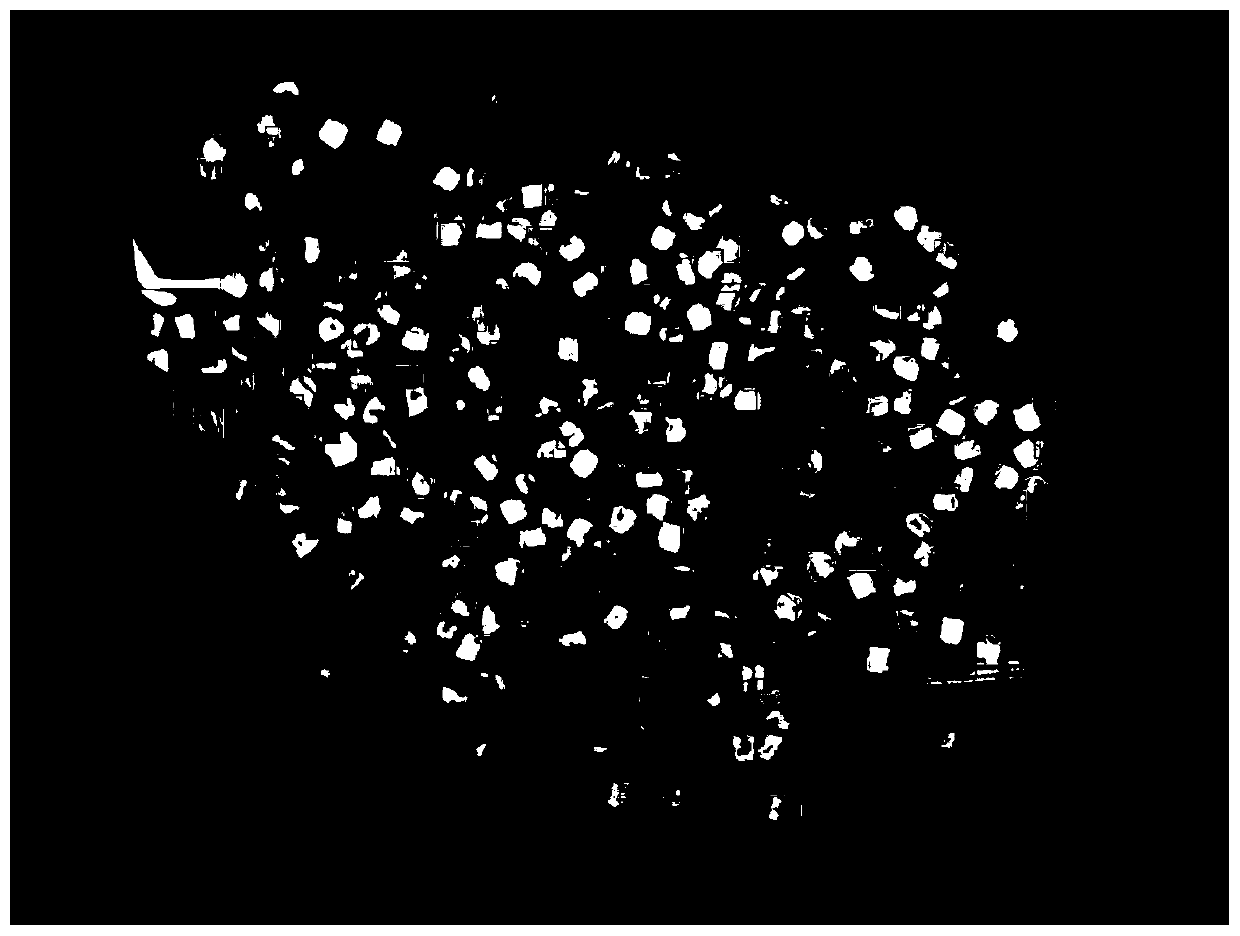

[0043] It should be pointed out that the steel material mentioned in the present invention is a strip-shaped steel material. Of course, in other embodiments, the steel material may also be construction-related materials such as round steel, steel pipe, steel ball, or other materials. The end face image of the steel pile can be obtained by taking pictures of the end face of the steel pile to be counted by a smart phone or other equipment with a camera function.

[0044] In this embodiment, the step S1 incl...

Embodiment 2

[0079] This embodiment provides an intelligent device, the intelligent device includes a processor and a memory; the memory stores a computer program; the processor is used to run the computer program, so as to realize the deep learning-based steel product provided in Embodiment 1 Identification method of size and quantity. The smart device may be a smart phone or a tablet computer with a camera function. Of course, it may also be a computer signal-connected to the imaging device.

Embodiment 3

[0081] This embodiment is a computer storage medium, which stores a computer program; when the computer program is run, it implements the deep learning-based steel size and quantity recognition method provided in Embodiment 1. Those of ordinary skill in the art can understand that all or part of the steps in the various methods of the above-mentioned embodiments can be completed by instructing related hardware through a program, and the program can be stored in a computer storage medium, and the storage medium includes a read-only memory ( Read-Only Memory, ROM), random access memory (Random Access Memory, RAM), programmable read-only memory (Programmable Read-only Memory, PROM), erasable programmable read-only memory (Erasable Programmable Read Only Memory, EPROM), one-time Programmable Read-Only Memory (One-time Programmable Read-Only Memory, OTPROM), Electrically-Erasable Programmable Read-Only Memory (EEPROM), Compact Disc Read-Only Memory, CD- ROM) or other optical disk s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com