Conjugated trapezoidal polymer-carbon nanotube composite material as well as preparation method and application thereof

A carbon nanotube and composite material technology, which is applied to active material electrodes, electrical components, electrochemical generators, etc., can solve the problems of high cost, complex process, low output, etc., and achieves low cost, simple preparation method, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a conjugated ladder polymer-carbon nanotube composite material, comprising the steps of: adding 5 mg of polybenzobisimidazole dibenzophenanthroline and 5 mg of carbon nanotubes with an outer diameter of 100 nm into methanesulfonic acid , stirred for 24 hours to obtain a mixed solution, wherein, in the mixed solution, the concentration of polybenzobisimidazole dibenzophenanthroline is 0.1mg / mL; Add water dropwise to the mixture, the rate of adding water is 20s / drop, and stir while adding, stop adding water when the solution turns from red to purple flocs, centrifuge to take flocs, and then wash the flocs with ethanol and water , ultrasonication, and centrifugation to obtain conjugated ladder polymer-carbon nanotube composites.

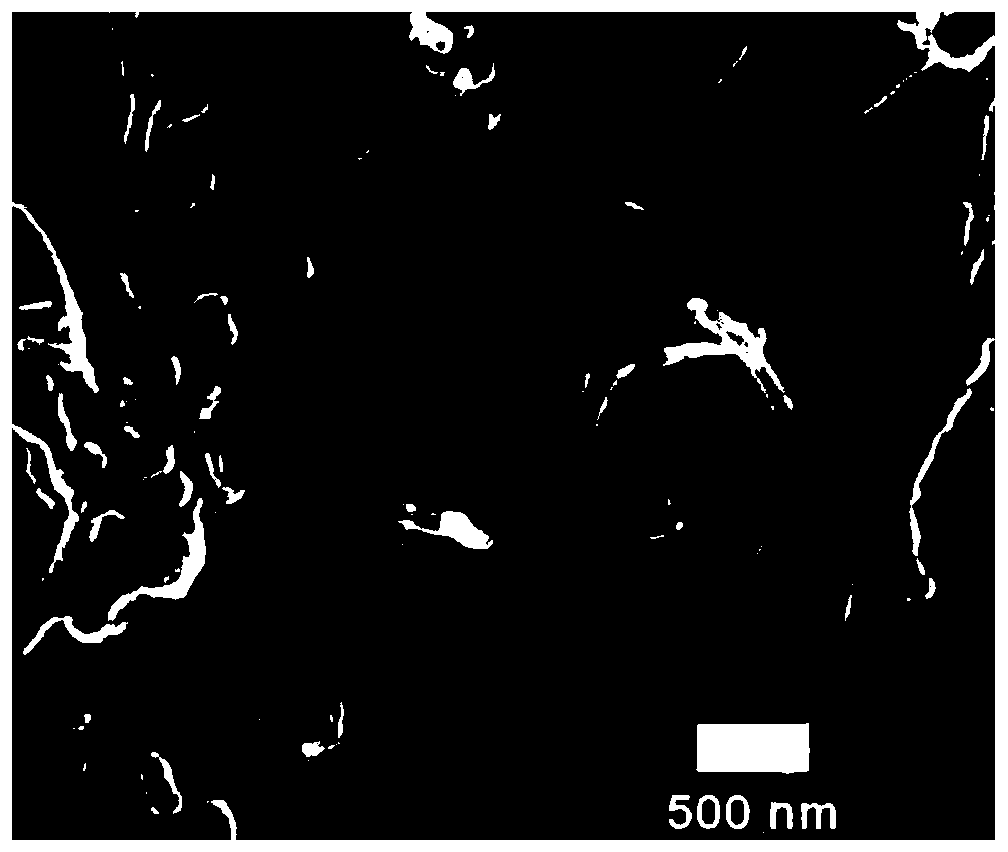

[0029] Take the above conjugated ladder polymer-carbon nanotube composite material for SEM scanning, the results can be found in figure 1 , figure 1 It is the SEM characterization figure of the conjugated ladder polymer-c...

Embodiment 2

[0031] A method for preparing a conjugated ladder polymer-carbon nanotube composite material, comprising the steps of adding 5 mg of polybenzobisimidazole dibenzophenanthroline and 10 mg of carbon nanotubes with an outer diameter of 100 nm into methanesulfonic acid , stirred for 12 hours to obtain a mixed solution, wherein the concentration of polybenzobisimidazole dibenzophenanthroline in the mixed solution was 0.1mg / mL; the mixed solution was placed in an ice bath at 0°C, and a micro syringe pump was used to inject Add water dropwise, the rate of adding water is 40s / drop, stir while adding, stop adding water when the solution turns from red to purple flocs, centrifuge to take the flocs, wash the flocs with ethanol and water, and ultrasonically , centrifuged to obtain conjugated ladder polymer-carbon nanotube composites.

[0032] Take the above conjugated ladder polymer-carbon nanotube composite material for TEM scanning, the results can be found in figure 2 , figure 2 It...

Embodiment 3

[0034] A method for preparing a conjugated ladder polymer-carbon nanotube composite material, comprising the steps of: adding 1 mg of polybenzobisimidazole dibenzophenanthroline and 10 mg of carbon nanotubes with an outer diameter of 10 nm into methanesulfonic acid , stirred for 24 hours to obtain a mixed solution, wherein, in the mixed solution, the concentration of polybenzobisimidazole dibenzophenanthroline was 0.01 mg / mL; the mixed solution was placed in a water bath at 30° C. Add water dropwise into the solution, the rate of adding water is 1s / drop, stir while adding, stop adding water when the solution turns from red to purple flocs, centrifuge to take the flocs, then wash the flocs with ethanol and water, Ultrasound and centrifugation to obtain the conjugated ladder polymer-carbon nanotube composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com