Convenient-to-clean homogenizer based on cosmetic production

A technology for convenient cleaning and cosmetics, applied in chemical instruments and methods, chemical/physical processes, mixers with rotating stirring devices, etc., can solve the problems of poor structure, unable to reduce the amount of cosmetic adhesion, and single stirring structure, etc., to achieve The effect of high mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

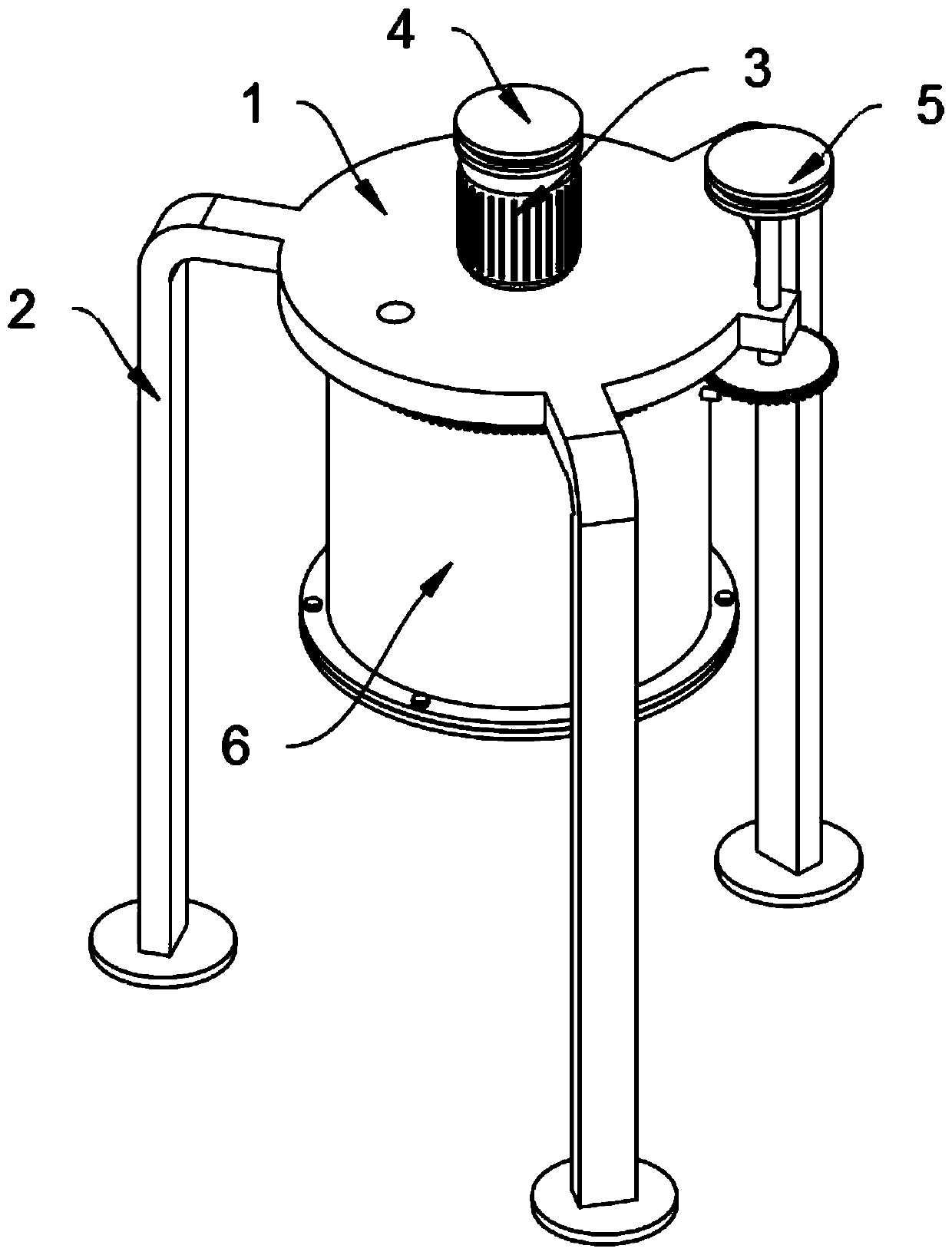

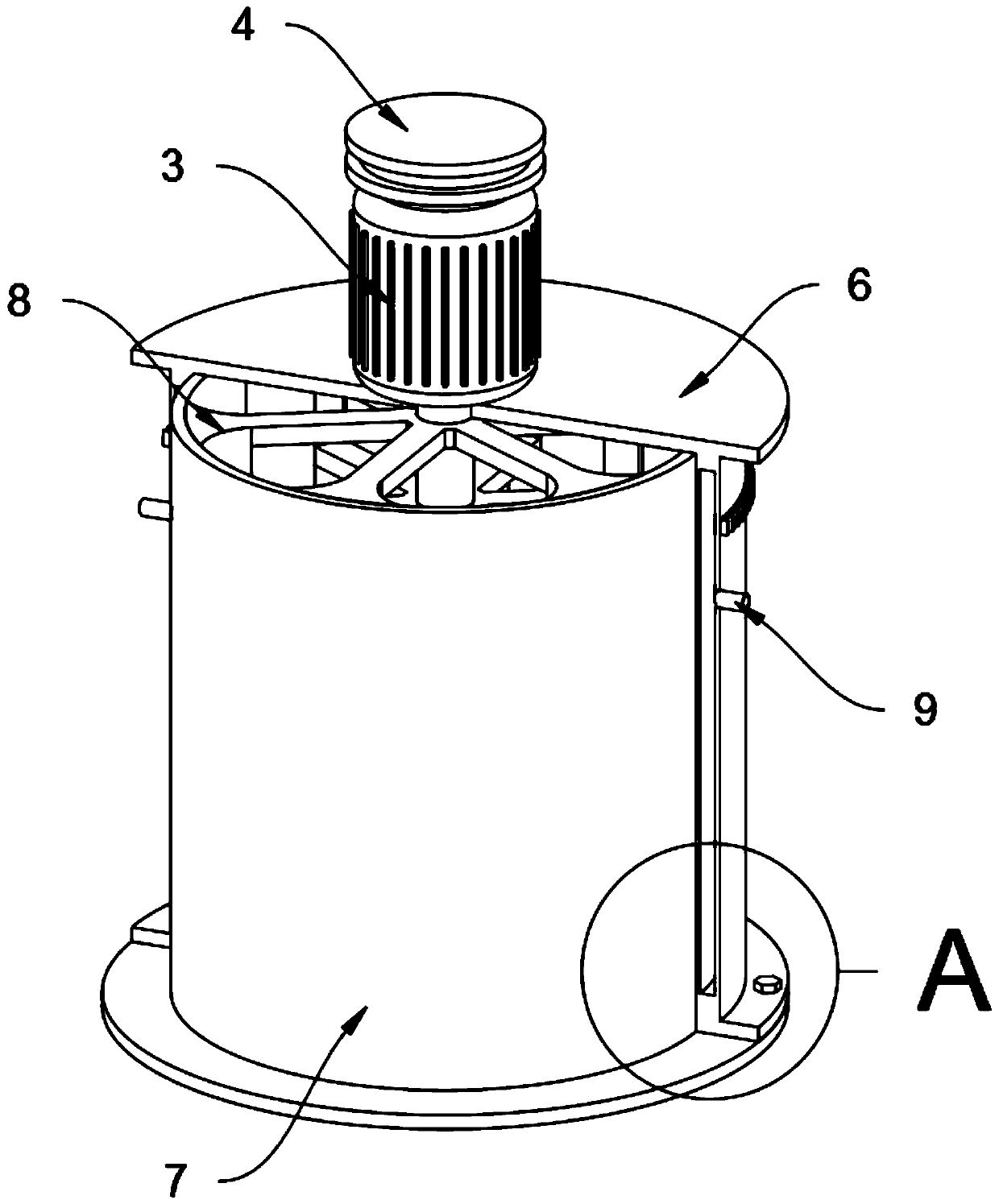

[0037] as attached figure 1 to attach Figure 8 Shown:

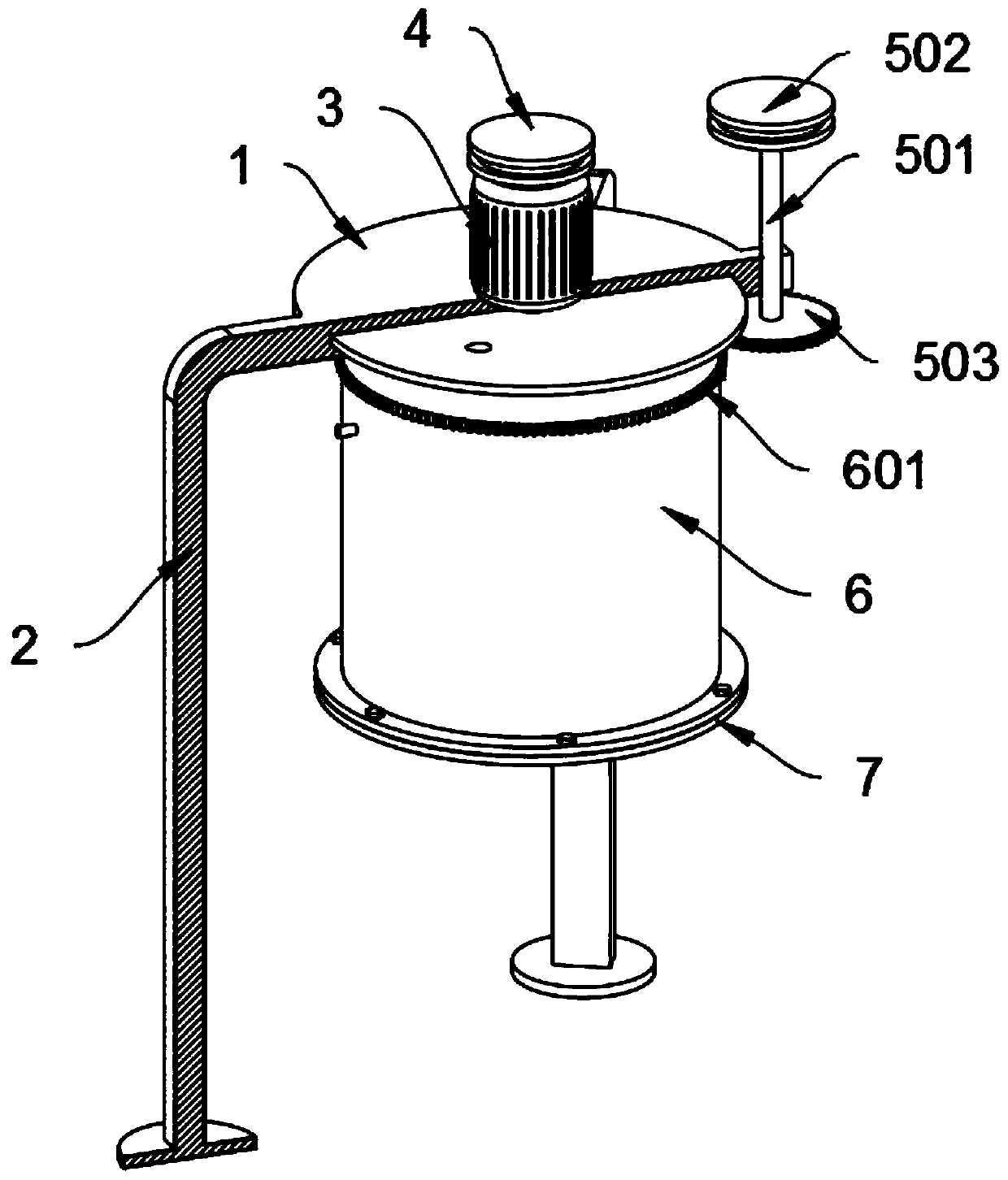

[0038] The present invention provides a homogenizer that is easy to clean based on the production of cosmetics, including a base 1; the base 1 is a disc-shaped structure, and the outer wall of the base 1 is welded with three support legs 2 in an annular array, and The top surface of the base 1 is fixedly connected with a servo motor 3 by bolts; the servo motor 3 is a double-headed motor, and one end of the servo motor 3 is connected to the stirring shaft 10, and the stirring shaft 10 is connected by a bolt The stirring blade structure 8 is fixedly connected; the other end of the servo motor 3 is fixedly connected with a pulley A4; the base 1 is rotatably connected with a transmission structure 5, and the base 1 is also rotatably connected with a Outer barrel6.

[0039] Reference as figure 2 , the transmission structure 5 includes a rotating shaft 501, a pulley B502 and a gear 503; the rotating shaft 501 is rotatably c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com