Intermediate alloy for titanium/carbon steel bimetal compounding and compounding process

An intermediate alloy and bimetal technology, applied in the field of bimetal composite materials, can solve the problems of uneven bonding strength, low bonding strength of composite material interface, low production efficiency, etc., and achieves easy promotion, wide composition range and good adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The master alloy for titanium / carbon steel bimetallic composite is composed of the following five components by atomic percentage, Ga: 20%, Cu: 20%, Zn: 20%, Mn: 20%, Fe: 20%.

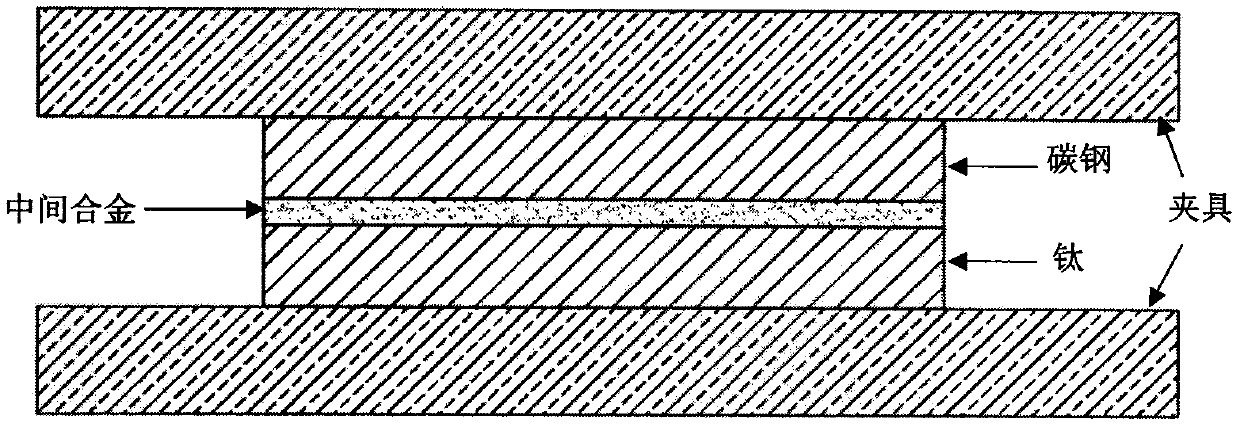

[0028] The specific composite process consists of the following steps:

[0029] (1) Preparation of master alloy: take high-purity metal powder according to the percentage, put the weighed metal powder of the above components into the stainless steel vacuum ball milling tank of the planetary ball mill, the ball-to-material ratio is 15:1, and add normal Heptane was used as a process control agent, and the mass of n-heptane accounted for 10% of the total mass of the ball material. The ball milling speed was 300r / min, and the milling time was 72h.

[0030] (2) Preparation of the base metal: Mechanically polish and clean the surface of the TC4 titanium plate with a length of 50 mm, a width of 20 mm, and a thickness of 2 mm and Q235 low-carbon steel to remove oil and impurities on the surface;

[003...

Embodiment 2

[0034] The master alloy for titanium / carbon steel bimetallic composite is composed of the following five components by atomic percentage, Ga: 5%, Cu: 15%, Zn: 35%, Mn: 35%, Fe: 10%.

[0035] The specific composite process consists of the following steps:

[0036] (1) Preparation of master alloy: take high-purity metal powder according to the percentage, put the weighed metal powder of the above components into the stainless steel vacuum ball milling tank of the planetary ball mill, the ball-to-material ratio is 15:1, and add normal Heptane was used as a process control agent, and the mass of n-heptane accounted for 10% of the total mass of the ball material. The ball milling speed was 300r / min, and the milling time was 72h.

[0037] (2) Preparation of the base metal: Mechanically polish and clean the surface of the TC4 titanium plate with a length of 50 mm, a width of 20 mm, and a thickness of 2 mm and Q235 low-carbon steel to remove oil and impurities on the surface;

[0038...

Embodiment 3

[0041] The master alloy for titanium / carbon steel bimetallic composite is composed of the following five components by atomic percentage, Ga: 5%, Cu: 15%, Zn: 35%, Mn: 35%, Fe: 10%.

[0042] The specific composite process consists of the following steps:

[0043] (1) Preparation of master alloy: take high-purity metal powder according to the percentage, put the weighed metal powder of the above components into the stainless steel vacuum ball milling tank of the planetary ball mill, the ball-to-material ratio is 15:1, and add normal Heptane was used as a process control agent, and the mass of n-heptane accounted for 10% of the total mass of the ball material. The ball milling speed was 300r / min, and the milling time was 72h.

[0044] (2) Preparation of the base metal: Mechanically polish and clean the surface of the TA2 titanium plate with a length of 50 mm, a width of 20 mm, and a thickness of 2 mm and 45 steel to remove oil and impurities on the surface;

[0045](3) Brazing:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com