A ship chimney desulfurization modification process

A technology for chimneys and ships, applied in ship propulsion, ship construction, ship parts, etc., can solve the problems of insufficient support for desulfurization devices, complicated operation steps, crowded space layout, etc., and achieve refitting process design and operation Reasonable, high structural strength , the effect of avoiding the transformation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

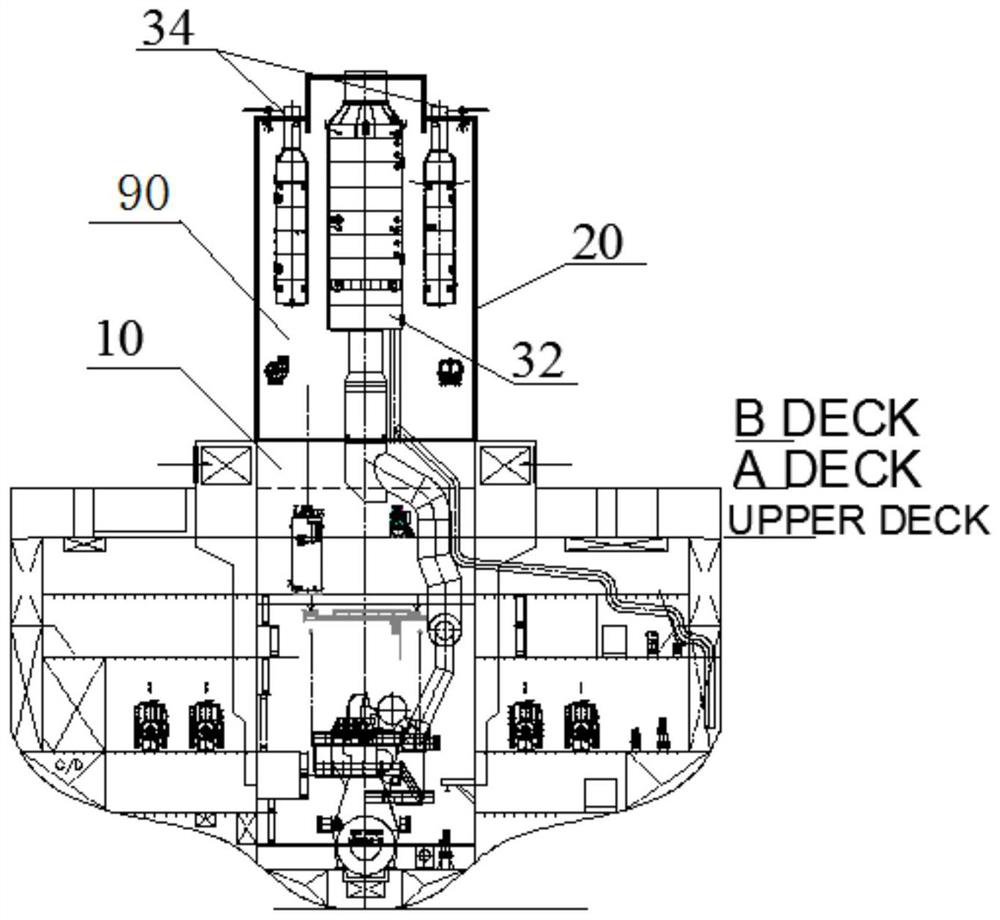

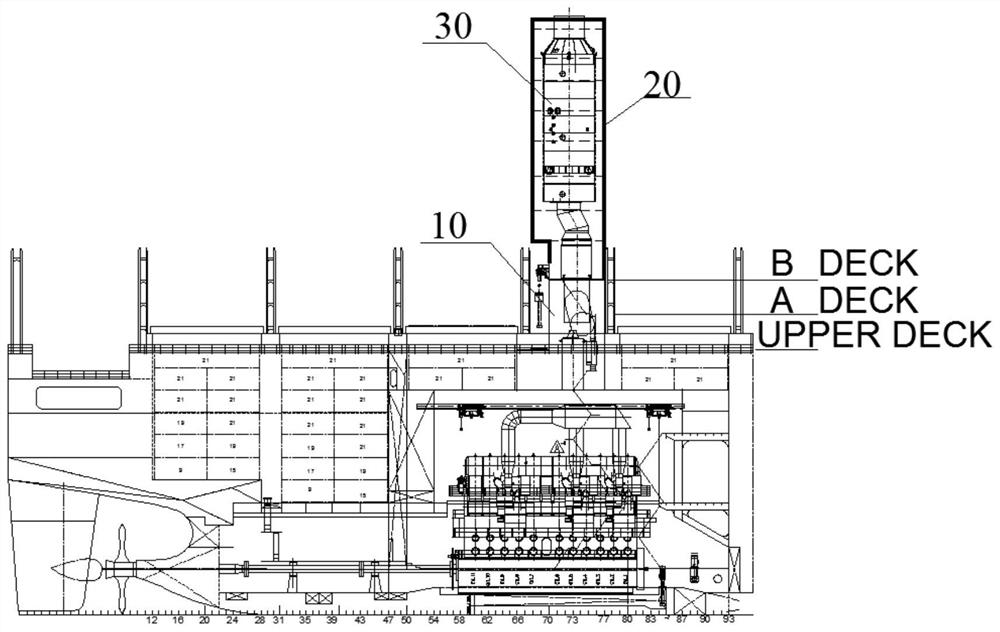

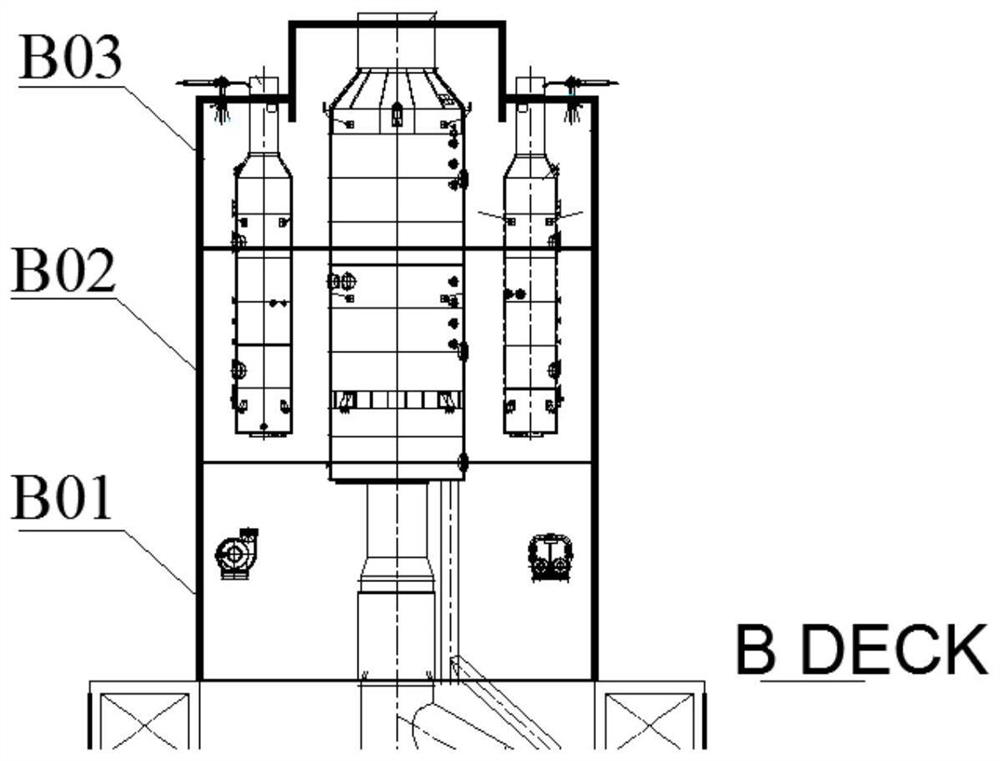

[0061] In the description of Embodiment 1 of the present invention, the present invention will be specifically described by taking the chimney desulfurization modification of "MSC" series large container ships as an example. The large container ship includes a superstructure on the main deck (UPPER DECK) and a main hull below the main deck. The superstructure includes A deck (A DECK) and B deck (B DECK) from bottom to top. The boat is moored at the pier.

[0062] Please refer to figure 1 and figure 2 , figure 1 It is a cross-sectional view of the ship chimney desulfurization modification effect according to the present invention, figure 2 It is a longitudinal sectional view of the ship chimney desulfurization modification effect according to the present invention, the ship chimney after refitting includes the old chimney reserved section 10 below the B deck and the desulfurization chimney general section 90 above the B deck, and the desulfurization chimney general section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com