System and method for remote monitoring in working process of coke pusher

A technology of remote monitoring system and working process, applied in coking ovens, petroleum industry, unloading devices, etc., can solve the problems of insufficient recycling and comprehensive utilization of chemical products and centralized processing, backward technical equipment, low economic benefits, etc., and achieve reduction Frequency of exchange verification and on-site inspection, highlighting substantive features, and the effect of improving the living environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

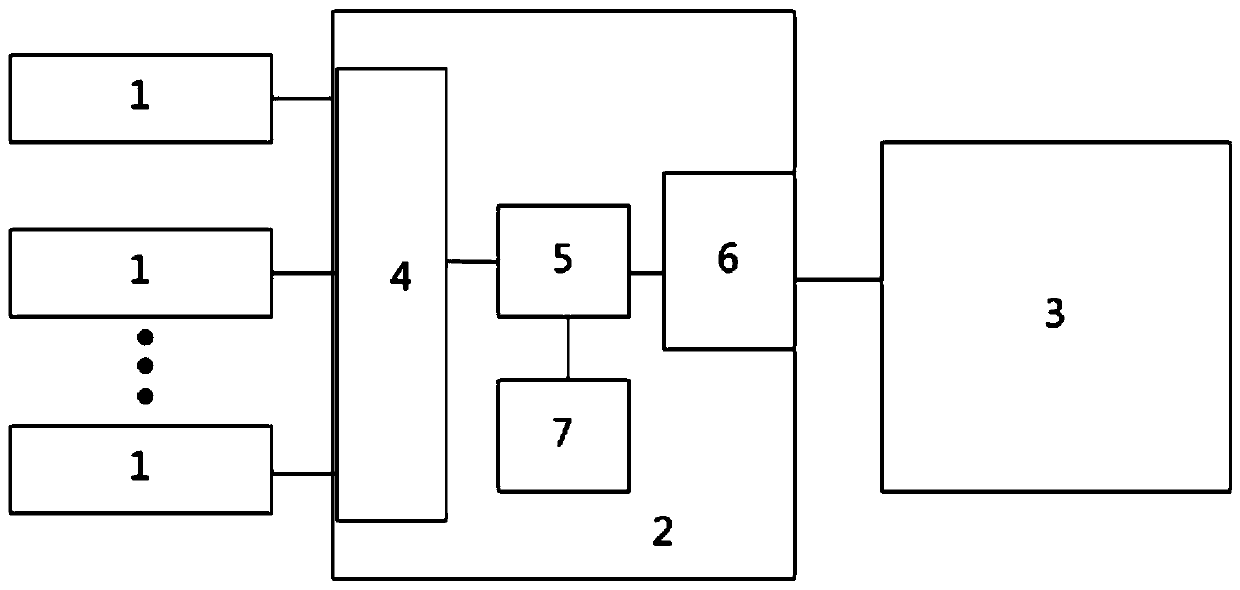

[0036] Such as figure 1 As shown, the present invention provides a remote monitoring system for the working process of a coke pusher, including a current transformer 1, an intelligent information collection terminal 2 and a production load monitoring platform 3;

[0037] This system is to remotely monitor the coke pusher of the enterprise, the number of the coke pusher is several, and the current transformer 1 is set on the coke pusher cable;

[0038] The current transformer 1 is connected with the intelligent information collection terminal 2, that is, a field network is formed through an Iora ad hoc network; the intelligent information collection terminal 2 obtains the working current of the coke pusher through the current transformer 1, every 10 seconds get once;

[0039] Described intelligent information collection terminal comprises Lora collection module 4, main control board 5, wireless transmission module 6 and power supply 7;

[0040] The Lora acquisition module 4 c...

Embodiment 2

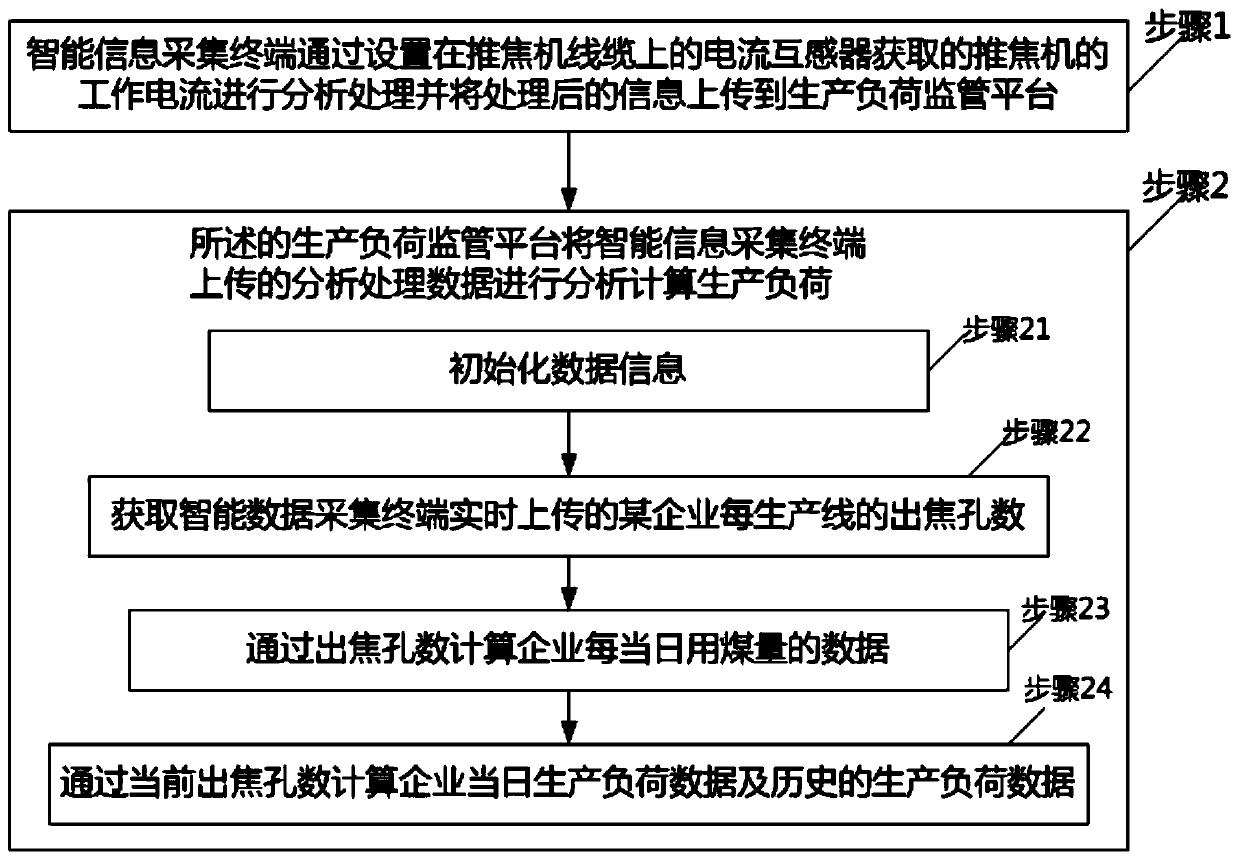

[0047] Such as figure 2 As shown, the technical solution of the present invention provides a remote monitoring method for the working process of the coke pusher, including the following steps:

[0048] Step 1: The intelligent information collection terminal analyzes and processes the working current of the coke pusher acquired by the current transformer set on the coke pusher cable, and uploads the processed information to the production load monitoring platform;

[0049] It should be noted that the process of analyzing and processing the acquired working current of the coke pusher by the intelligent information collection terminal includes:

[0050] When the working current of a coke pusher exceeds the first preset value of the current, it is recorded as the start of a coke push; when the working current of the coke pusher is lower than the second threshold of the current, it is counted as the end of a coke push, and each The start time of machine coke pushing and the count...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com