Method for preparing pyrolysis oil and limonene by pressurized pyrolysis of waste tires

A technology for waste tires and pyrolysis oil, which is applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, organic chemistry, etc. Improve the effect of mass ratio and concentration increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

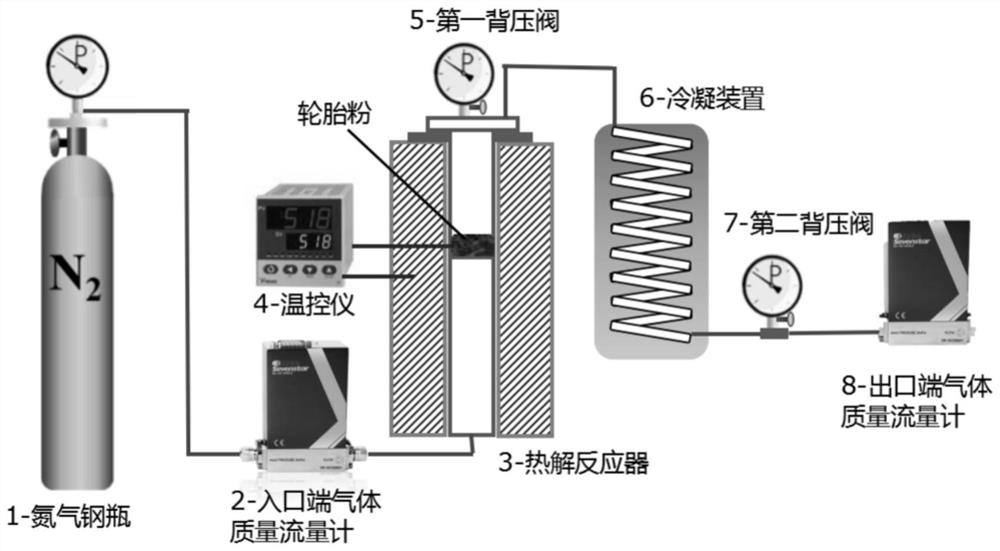

[0027] The invention provides a method for preparing pyrolysis oil and limonene by pressurized pyrolysis of waste tires. figure 1 The pyrolysis system shown includes: a nitrogen cylinder 1, an inlet gas mass flow meter 2, a pyrolysis reactor 3, a temperature controller 4, a first back pressure valve 5, a condensation device 6, a second back pressure valve 7, Gas mass flow meter 8 at the outlet end.

[0028] in:

[0029] The first back pressure valve 5 and the second back pressure valve 7 control the pressure in the system, the temperature controller 4 controls the pyrolysis temperature in combination with the heater of the pyrolysis reactor, the gas mass flow meter 2 at the inlet end, and the gas mass flow meter at the outlet end The flow meter 8 monitors and controls the flow of the shielding gas.

[0030] The pyrolysis reactor 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com