Method and system for measuring highly reflective objects based on laser speckle limit-constrained projection

A technology of extreme constraints and laser speckle, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of three-dimensional measurement of highly reflective objects, complex measurement system, and difficulty in implementation, so as to improve the accuracy of three-dimensional measurement and reduce the impact , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

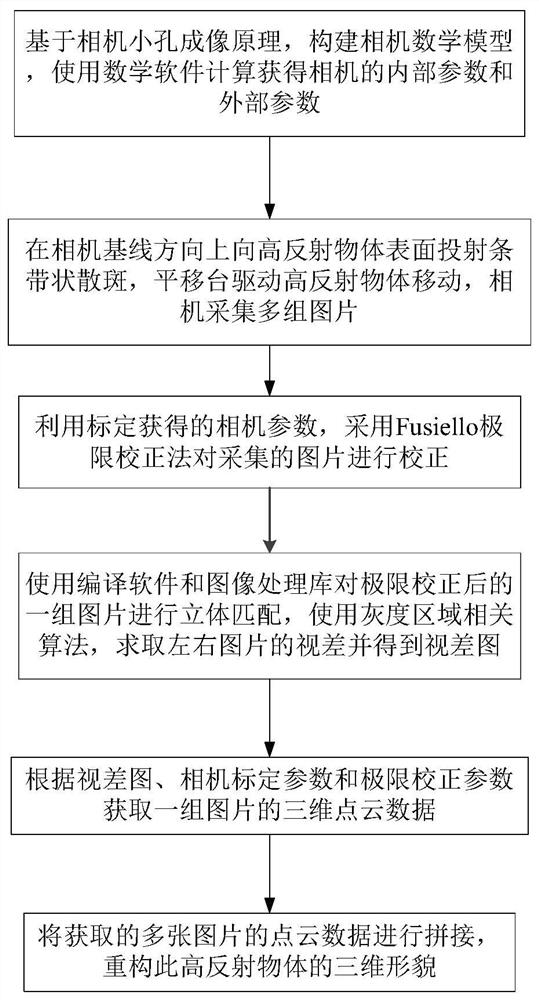

[0020] Such as figure 1 As shown in , this method of measuring highly reflective objects based on laser speckle limit-constrained projection includes the following steps:

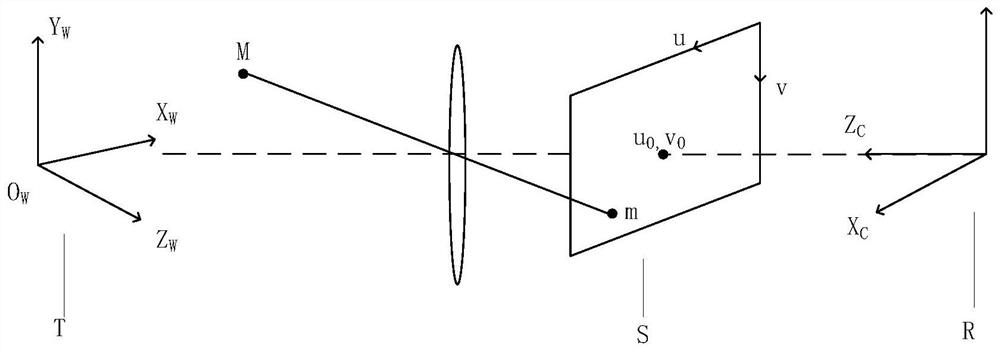

[0021] (1) Based on the principle of camera pinhole imaging, construct a mathematical model of the camera, and use mathematical software to calculate the internal and external parameters of the camera;

[0022] (2) Project stripe-shaped speckle on the surface of the highly reflective object in the direction of the camera baseline, the translation stage drives the highly reflective object to move, and the camera collects multiple sets of pictures;

[0023] (3) Utilize the camera parameters obtained in step (1) to calibrate, and use the Fusiello limit correction method to correct the pictures collected in step (2);

[0024] (4) Use compiling software and image processing library to carry out stereo matching to a group of pictures after step (2) limit correction, use gray scale area correlation algorithm, ask...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com