Multi-motor cluster system driving control device, method and system

A cluster system and motor control unit technology, which is applied in motor generator control, control of electromechanical transmission, electronic commutation motor control, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to make the objectives, technical solutions and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings in the embodiments of the present invention.

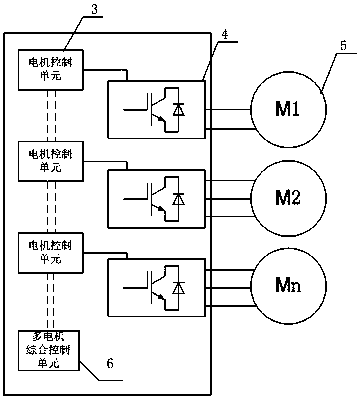

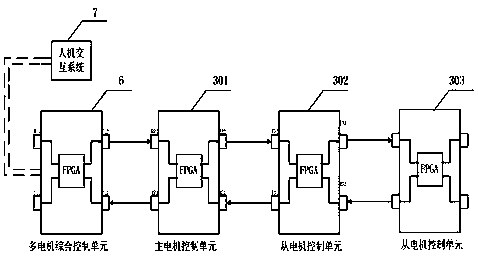

[0058] This embodiment discloses a variable frequency drive control device for multi-motor clusters, which participates in such figure 1 as shown. The device includes a variable frequency drive 4 , a plurality of motor control units 3 , and a multi-motor integrated control unit 6 . Among the multiple motor control units, one is set as the main motor control unit, and the rest is set as the slave motor control unit. The connection relationship between the multi-motor integrated control unit 6 and the multiple motor control units 3 is as follows: figure 2 shown.

[0059] The slave motor control unit is used to receive the control command from the master motor control unit, and control the variable fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com