Permanent magnet synchronous motor composite current constraint control system and construction method thereof

A technology of permanent magnet synchronous motor and constraint control, which is applied in the direction of control system, motor control, vector control system, etc., and can solve problems such as complex algorithm implementation, model uncertainty and interference difficulties, and many parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

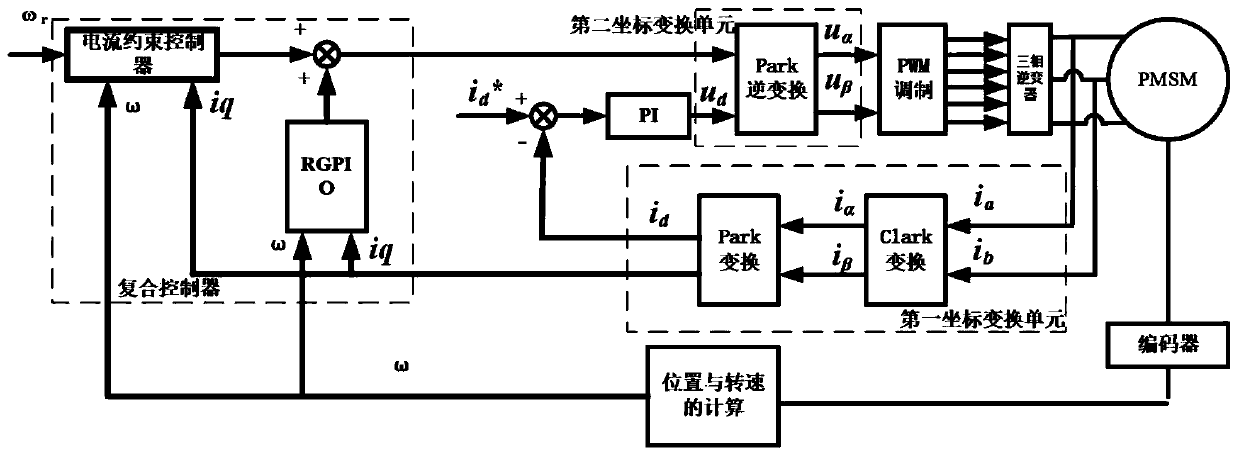

[0103] Such as figure 1 As shown, a constraint control system for compound current of permanent magnet synchronous motor, including;

[0104] The first coordinate transformation unit, including the Park inverse transformation unit, is used to convert the three-phase output current of the permanent magnet synchronous motor into the d-axis current i d and q-axis current i q ;

[0105] The encoder receives the angular displacement of the permanent magnet synchronous motor rotor, and is used to detect and calculate the spatial phase of the permanent magnet synchronous motor rotor magnetic pole axis and the actual angular velocity ω of the rotor;

[0106] PI controller, receiving d-axis current i d and reference current Output d-axis voltage u d ;

[0107] The reduced-order proportional observer receives the actual angular velocity ω and the q-axis current i of the permanent magnet synchronous motor q , output the estimated value of the time-varying disturbance, which is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com