Integrated weak light triggering gas switch circuit based on transformer and working method thereof

A technology of gas switch and transformer, which is applied in the field of integrated weak light trigger gas switch circuit, can solve the problems of increased complexity, lower reliability of gas switch trigger, large trigger light energy, etc., to achieve reduced volume and easy control of trigger time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

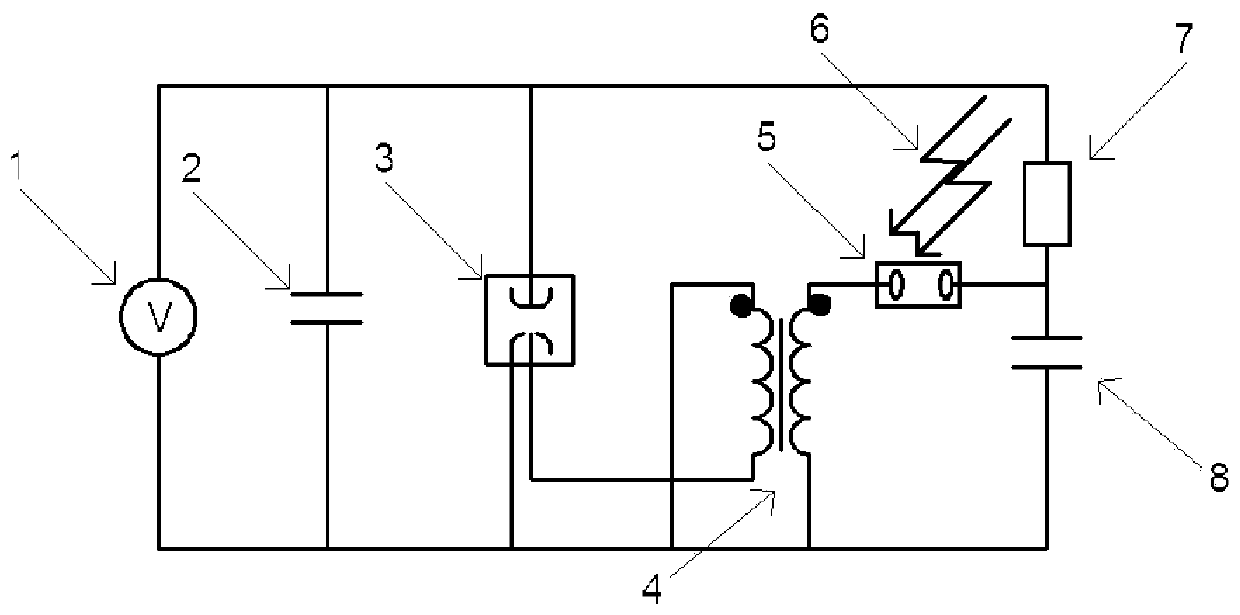

[0035] Such as figure 1 As shown, the integrated low-light trigger gas switch 3 circuit based on the transformer 4, the gas switch 3, the transformer 4, the photoconductive switch 5, the voltage dividing resistor 7 and the trigger capacitor 8;

[0036] The high voltage pole of the gas switch 3 is connected to the voltage dividing resistor 7, the ground electrode of the gas switch 3 is grounded, and the trigger pole of the gas switch 3 is connected to the secondary side of the transformer 4;

[0037] One terminal on the primary side of the transformer 4 is connected to one end of the photoconductive switch 5, and the other end of the photoconductive switch 5 is respectively connected to a voltage dividing resistor 7 and a trigger capacitor 8, and the trigger capacitor 8 and the voltage dividing resistor 7 form an RC voltage divider circuit; by adjusting The component parameters of the RC voltage divider circuit are used to adjust the preset value of the trigger component; the o...

Embodiment 2

[0040]In this embodiment, the high voltage pole of the gas switch 3 and the voltage dividing resistor 7 are connected to the positive pole of a main circuit power supply 1 , and the negative pole of the main circuit power supply 1 is grounded; the main circuit power supply 1 is connected in parallel with a main energy storage capacitor 2 . The trigger capacitor 8 is connected to the gas switch 3 and the main circuit power supply 1 through the voltage dividing resistor 7, and the trigger circuit can directly obtain the voltage and energy required for the trigger system from the main circuit or the electric field of the gas switch 3 without adding a charging power supply to the trigger circuit. The volume and circuit complexity of the switching system can be reduced.

[0041] The photoconductive switch 5 works in a nonlinear working mode. The photoconductive switch 5 is in a non-linear working mode, and the required triggering light energy is only a few microjoules to tens of mi...

Embodiment 3

[0046] In this embodiment, the main circuit power supply 1 charges the main energy storage capacitor 2 with a capacity of 22nF to 50kV, and the charging time is 30 microseconds, and the self-breakdown voltage of the gas switch 3 connected in parallel with the main energy storage capacitor 2 is about 65kV , the voltage dividing resistor 7 is a 20kΩ high-voltage glass glaze resistor, and the trigger energy storage capacitor is a high-voltage ceramic capacitor with a capacity of 3.3nF and a withstand voltage of 15kV. Therefore, the voltage of the trigger energy storage capacitor is 8kV 30 microseconds after the start of charging, and the conduction The component (photoconductive switch 5) is a GaAs semi-insulated photoconductive switch 5 with a length, width, and height of 6mm×6mm×3mm placed in insulating oil. The pass element makes it enter the conduction state, so that the capacitor connected to the trigger energy storage discharges the primary side of the transformer 4, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Divider resistor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com