Quick replacing process for 600kg/m-or-under special-shaped blank continuous casting tundish

A special-shaped billet continuous casting and tundish technology, which is applied in the field of steelmaking and continuous casting, can solve the problems of vibration and other problems, and achieve the effect of shortening the process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

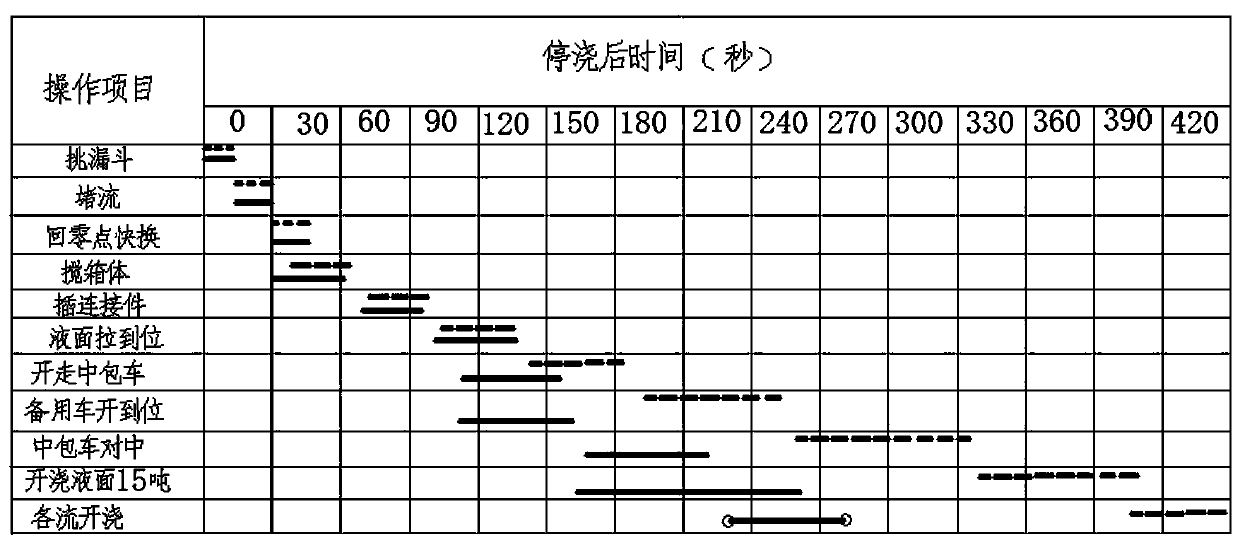

[0026] The capacity of the tundish is 30 tons, the section thickness of the mold is 130mm, and the length of the mold is 1100mm. The specific implementation process is as follows:

[0027] Step 1: About 10 minutes before changing the tundish, carry out the slag reduction operation on the mold slag in the crystallizer.

[0028] Step 2: After each flow is blocked, operate the operation box: return the pulling speed to 0 → stop pulling and straightening → click the quick change mode on the P3 plate and confirm that the quick change button light is always on; immediately use the L-shaped oxygen tube after the flow is blocked Stir the box → put the plug-in connectors in the liquid steel → open the middle charter car and start the tension leveling at the same time to pull the liquid level of the crystallizer to a position 600mm away from the upper mouth of the crystallizer, stop the tension leveling and prepare for pouring.

[0029] During the above operation process, the long cork ...

Embodiment 2

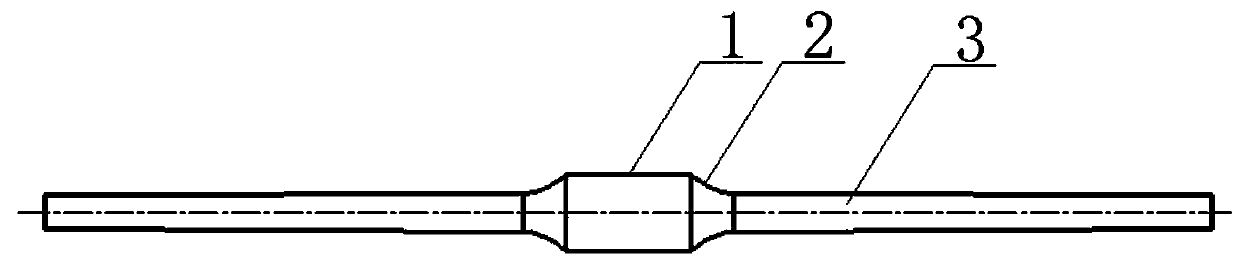

[0034] A special-purpose centering device for the quick-change process of the continuous casting tundish of profile billets below 600kg / m as claimed in claim 1, the structure of which includes a columnar intermediate body 1, conical extensions 3 are arranged at both ends of the intermediate body, and There is an arc-shaped transition section 2 in between, in which the length of the columnar intermediate body is 54mm, the diameter is 33mm, the length of the arc-shaped transition section is 18mm, and the radius of the arc is 30mm. The outer end diameter of the conical extension is 14.5mm, and the inner end diameter is 16mm , length 205㎜.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com