Aldehyde-free plate

A technology for board and particle board, applied in the field of formaldehyde-free board, can solve the problems of high cost and complicated preparation process, and achieve the effects of low cost, simple production process and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

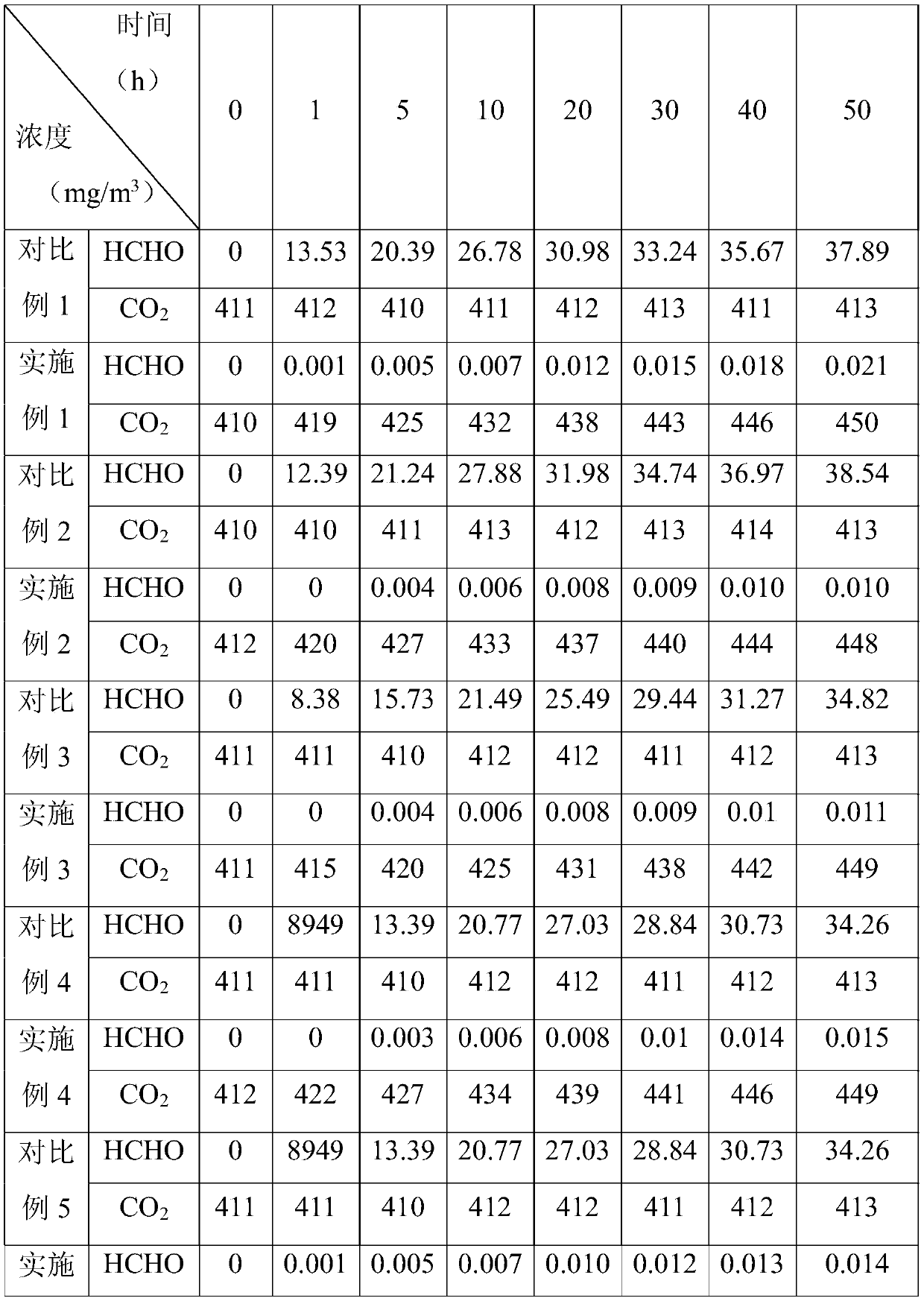

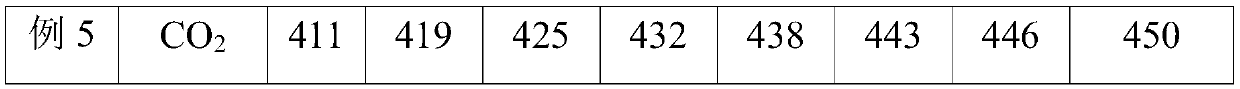

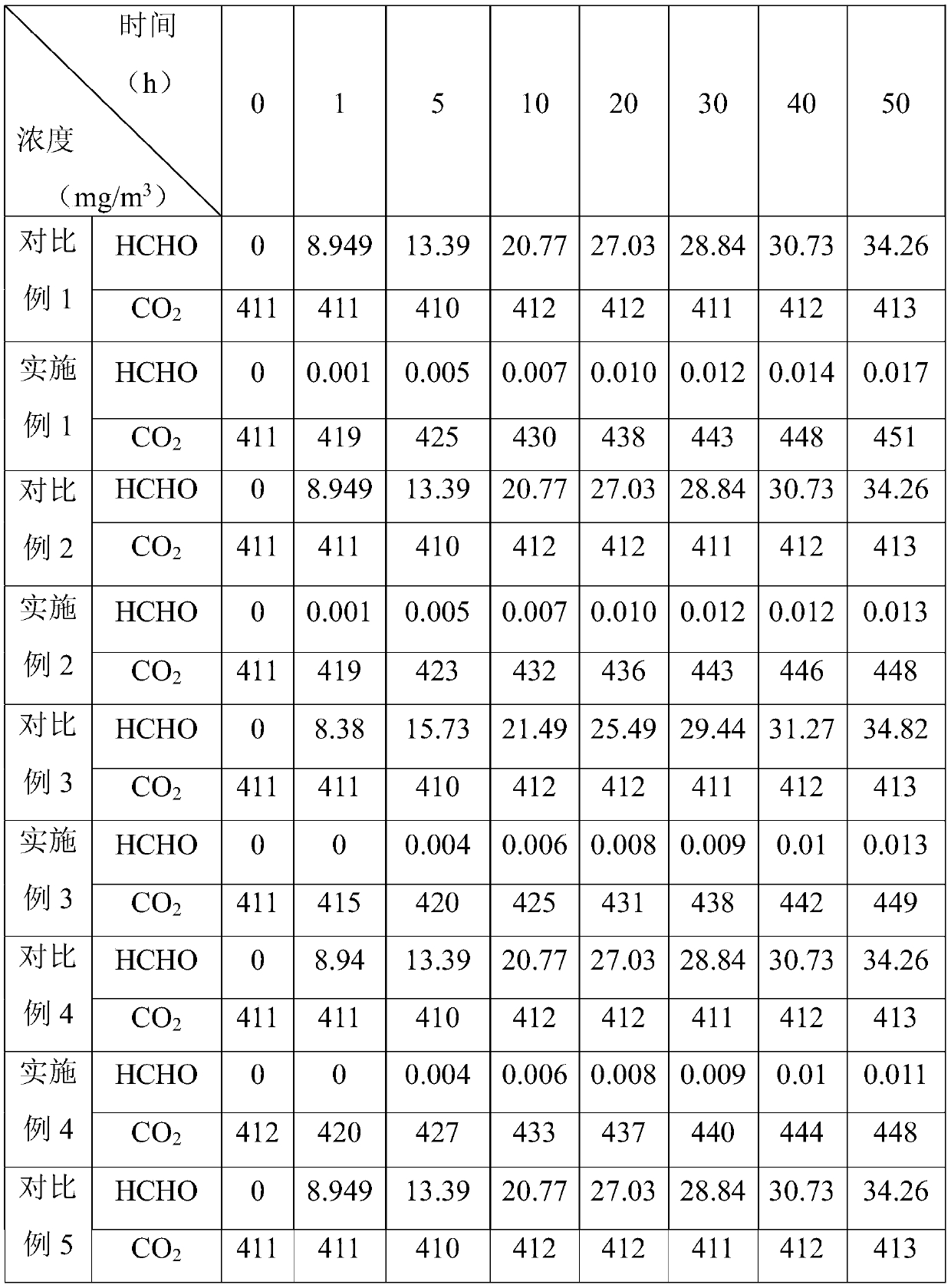

Examples

Embodiment 1

[0041] Manganese dioxide catalyst preparation

[0042] Weigh 1.57g KMnO 4 , 1.69g MnSO 4 ·H 2 O and 0.23g of glucose were dissolved in 150ml of deionized water, mixed thoroughly, and reacted in a water bath at 70°C for 7 hours. After the reaction was completed, 35mL of deionized water was added to dilute to obtain a manganese dioxide catalyst slurry. Alternatively, the reaction product is directly filtered and dried at 60° C. to obtain a powder catalyst.

[0043] Wood-based panel coating

[0044] The single-layer board is coated according to the catalyst coating amount of 0.004g / cm 2 The above-mentioned manganese dioxide catalyst slurry was coated, and pressed into plywood by hot pressing at a pressing temperature of 150° C., a pressure of 5 MPa, and a hot pressing time of 4 minutes. The surface layer of plywood is based on the catalyst coating amount of 0.005g / cm 2 The manganese dioxide catalyst slurry described above was coated. Blow drying at 70°C to obtain formaldeh...

Embodiment 2

[0047] Manganese dioxide catalyst preparation

[0048] Weigh 1.57g KMnO 4 , 2.01g MnSO 4 ·H 2 O and 0.15 g of glucose were dissolved in 130 ml of deionized water, mixed thoroughly, and reacted in a water bath at 60° C. for 6 hours. After the reaction, 40 mL of deionized water was added to dilute to obtain a manganese dioxide catalyst slurry. Alternatively, the reaction product is directly filtered and dried at 60° C. to obtain a powder catalyst.

[0049] Wood-based panel coating

[0050] The single-layer board is coated according to the catalyst coating amount of 0.004g / cm 2 Coating the above-mentioned manganese dioxide catalyst slurry, adding urea-formaldehyde adhesive and pressing into plywood by hot pressing, the pressing temperature is 160° C., the pressure is 6 MPa, and the hot pressing time is 4.5 min. The surface layer of plywood is based on the catalyst coating amount of 0.005g / cm 2 The manganese dioxide catalyst slurry described above was coated. Blow drying at...

Embodiment 3

[0053] Manganese dioxide catalyst preparation

[0054] Weigh 1.57g KMnO 4 , 1.82g MnSO 4 ·H 2 O and 0.21g of citric acid were dissolved in 130ml of deionized water, mixed thoroughly and then reacted in a water bath at 80°C for 9h. After the reaction was completed, 40mL of deionized water was added to dilute to obtain a manganese dioxide catalyst slurry. Alternatively, the reaction product is directly filtered and dried at 60° C. to obtain a powder catalyst.

[0055] Wood-based panel coating

[0056] The single-layer board is coated according to the catalyst coating amount of 0.006g / cm 2 Coating the above-mentioned manganese dioxide catalyst slurry, adding urea-formaldehyde adhesive and pressing into plywood by hot pressing, the pressing temperature is 155° C., the pressure is 7 MPa, and the hot pressing time is 4.5 min. The surface layer of plywood is based on the catalyst coating amount of 0.007g / cm 2 The manganese dioxide catalyst slurry described above was coated. Bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com