Mortar water retention and heat preservation polymer additive, and preparation method and equipment

A technology of polymers and additives, applied in chemical instruments and methods, mixers, chemical/physical processes, etc., can solve the problem that the mixing efficiency cannot be effectively improved, and it cannot better meet the use of buildings and the promotion of industrialization The effect is not good enough, etc., to achieve the effect of reducing air bubbles, improving construction quality, and good compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

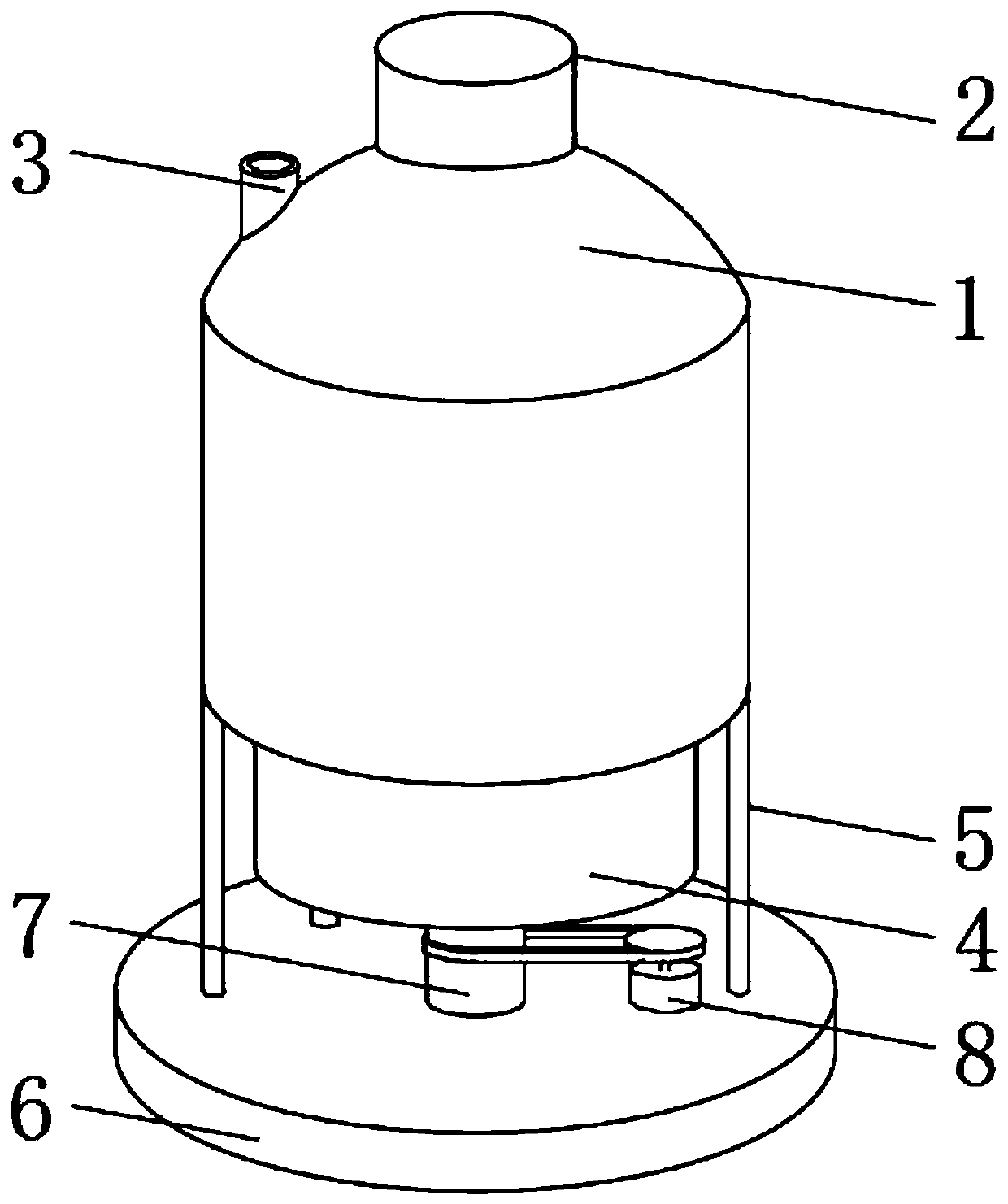

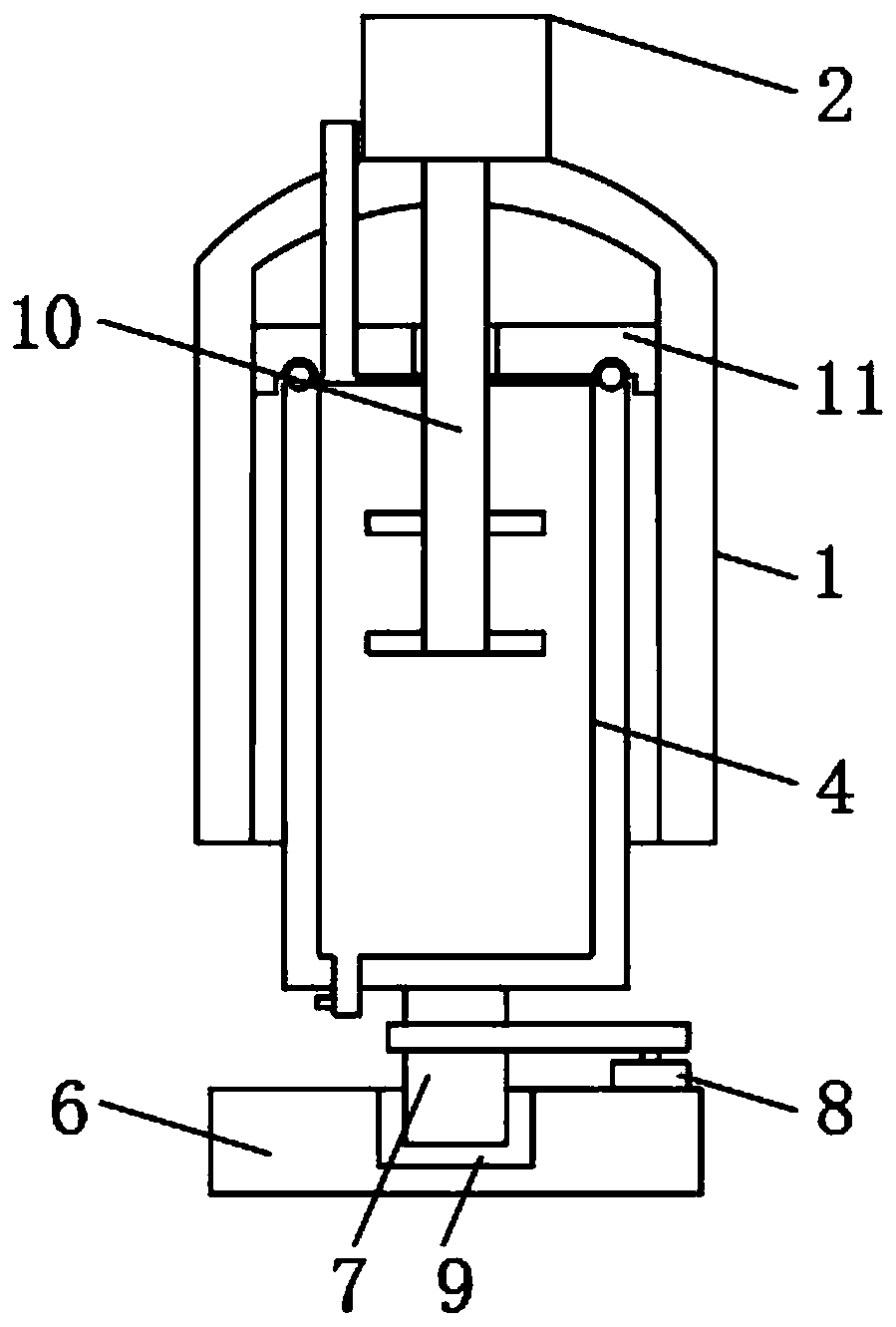

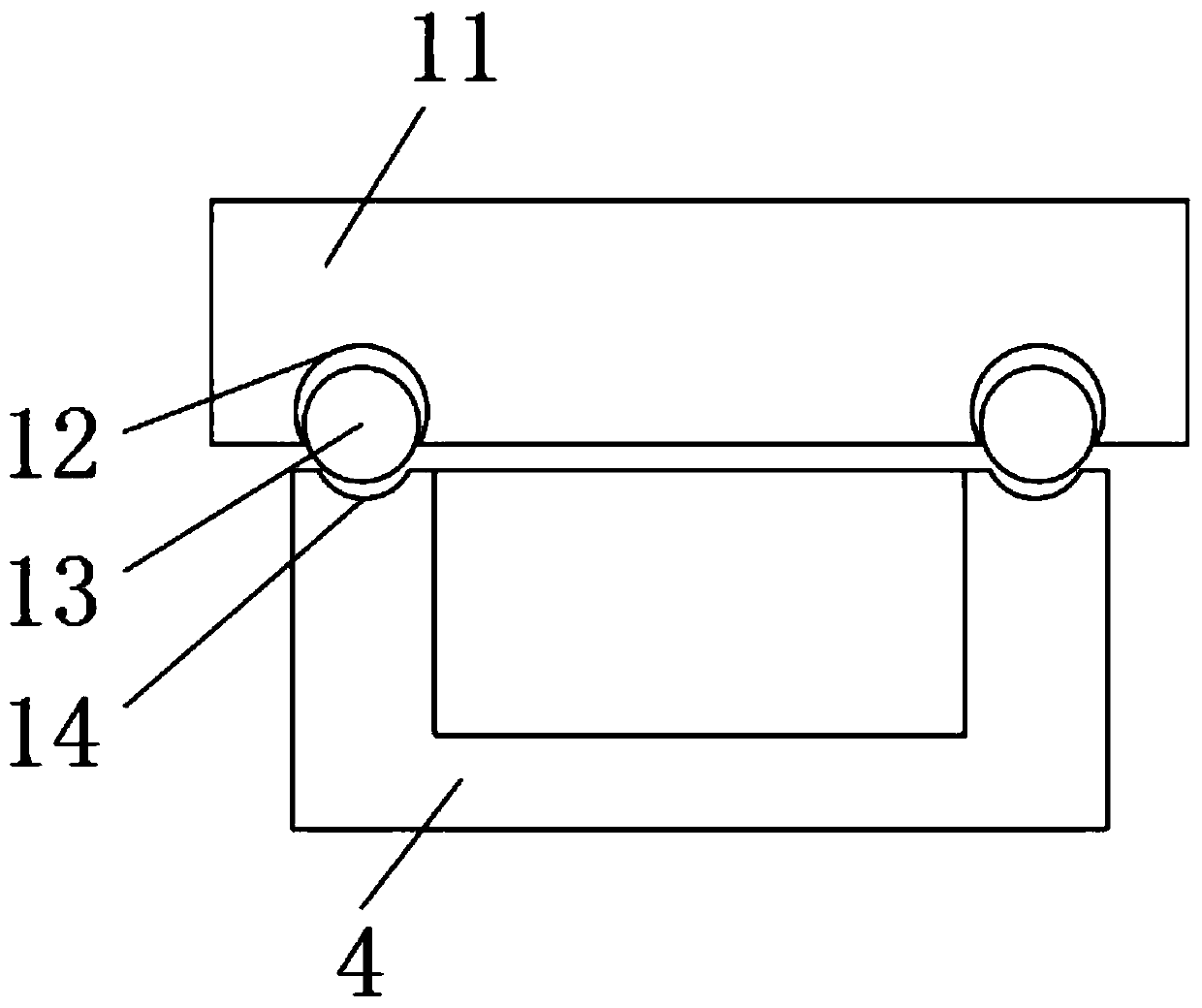

[0028] see Figure 4 , the mortar water-retaining and heat-insulating polymer additive provided in this embodiment is made of the following parts by weight: 45 parts of water-retaining agent, 1.5 parts of coagulation-adjusting enhancer, 6 parts of water-reducing agent, 0.2 part of air-entraining agent, deionized water 81 parts, 1 part of aggregate, 0.1 part of defoamer, 0.2 part of accelerator, and 1.5 parts of waterproofing agent.

[0029] The preparation method of the aforementioned mortar water-retaining and heat-retaining polymer additive comprises the following steps:

[0030] S1: Weighing, corresponding to weighing the components of each weight ratio, and placing them independently;

[0031] S2: Add water-retaining agent, coagulation-adjusting enhancer, water-reducing agent, air-entraining agent, deionized water, aggregate, quick-setting agent, waterproofing agent to the reaction kettle in turn and stir, and heat up to 80 degrees Celsius, then add defoamer , the defoam...

Embodiment 2

[0042] The mortar water-retaining and heat-retaining polymer additive, preparation method and equipment provided in the embodiment of the present invention are basically the same as in Example 1, except that:

[0043] In this embodiment, the mortar water-retaining and heat-retaining polymer additive is made of the following components by weight: 50 parts of water-retaining agent, 2 parts of coagulation-adjusting enhancer, 6.5 parts of water-reducing agent, 0.5 part of air-entraining agent, and 85 parts of deionized water. 2 parts, aggregate 2 parts, defoamer 0.3 parts, accelerator 0.2 parts, waterproofing agent 2 parts.

Embodiment 3

[0045] The mortar water-retaining and heat-retaining polymer additive, preparation method and equipment provided in the embodiment of the present invention are basically the same as those in Examples 1 and 2, except that:

[0046] In this embodiment, the mortar water-retaining and heat-retaining polymer additive is made of the following components by weight: 55 parts of water-retaining agent, 2.5 parts of coagulation-adjusting enhancer, 7 parts of water-reducing agent, 0.7 part of air-entraining agent, and 89 parts of deionized water. 3 parts, 3 parts of aggregate, 0.2 parts of defoamer, 0.3 parts of accelerator, 2.5 parts of waterproofing agent.

[0047] The present invention simultaneously improves the mortar water-retaining and heat-retaining polymer additive, the preparation method and the equipment, while ensuring the dispersibility of the mortar, it improves the construction quality of the mortar, makes the mortar more stable, has better compression resistance, and its st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com