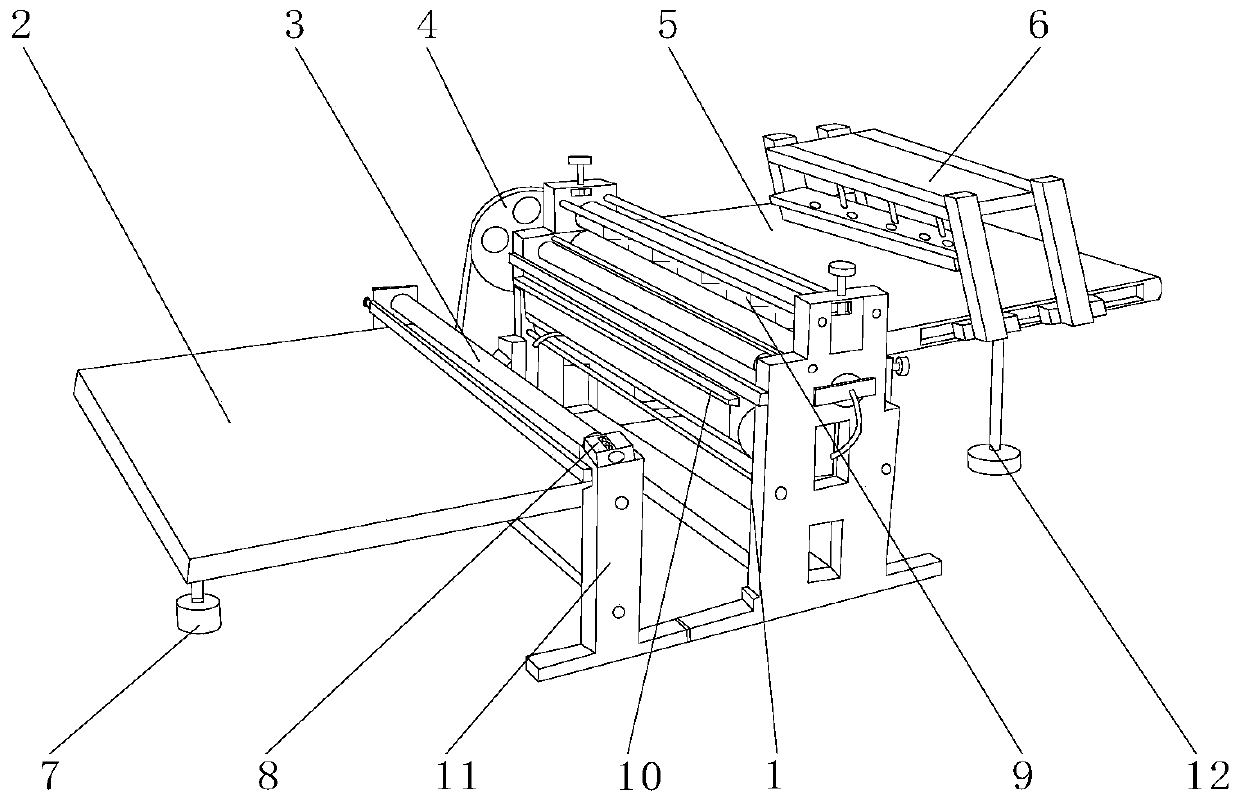

Waxing device for fabric production

A cloth and material feeding technology, which is applied to the cleaning device for processing textile materials, the device for coating liquid on the surface, and the configuration of equipment for processing textile materials. Operation and other problems, to achieve the effect of increasing waxing effect, convenient fixing and disassembly, and increasing cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

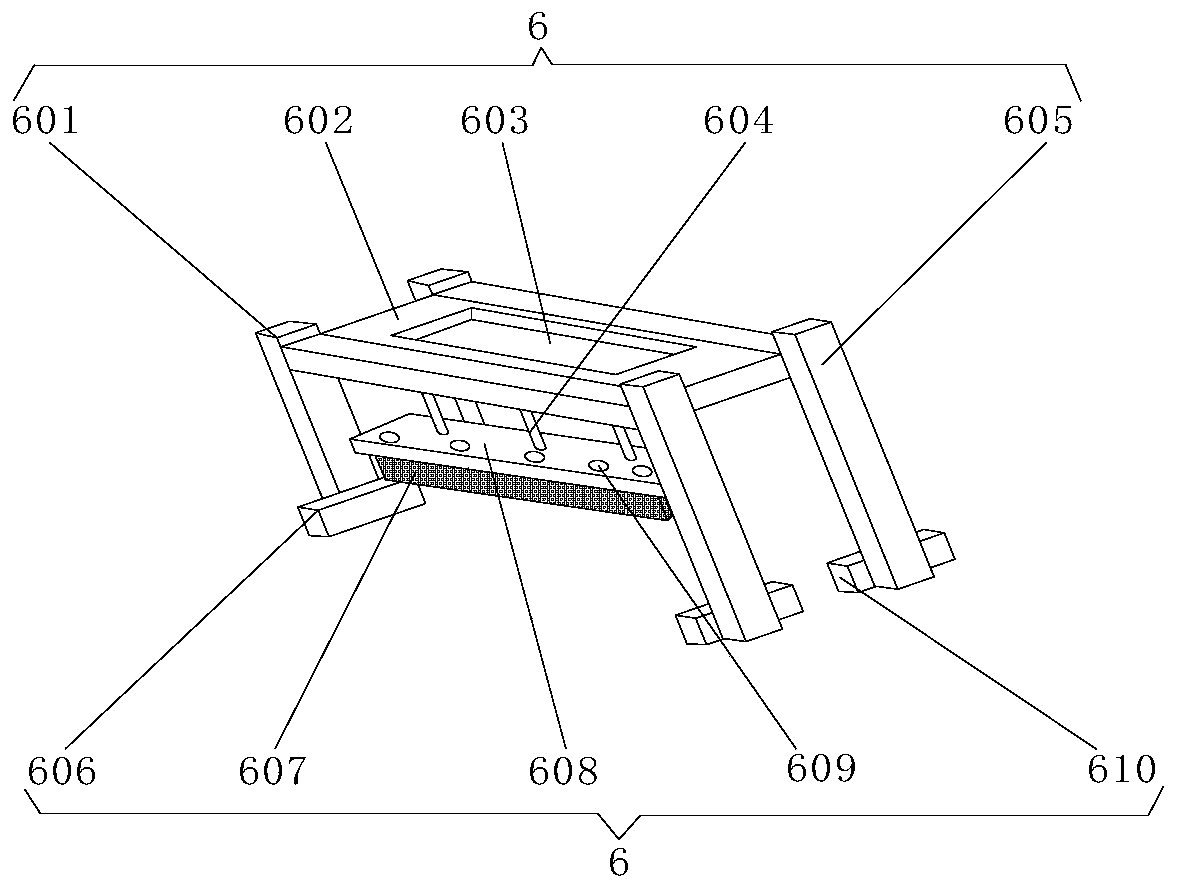

[0029] Embodiment one: if image 3 , 4As shown, the sliding type lifting cleaning rack mechanism 6 includes No. 1 support 601, support plate 602, placement groove 603, cylinder 604, No. 2 support 605, No. 1 slider 606, cleaning brush 607, cleaning plate 608, drip irrigation hole 609, No. 2 slider 610, support plate 602 is located inside the upper end of No. 1 bracket 601, No. 1 slider 606 is located inside the lower end of No. 1 bracket 601, placement slot 603 is located at the upper end of support plate 602, and No. 2 bracket 605 is located on support plate 602 On one side, the No. 2 slider 610 is located at the lower end side of the No. 2 support 605, the cylinder 604 is located at the lower end of the support plate 602, the cleaning plate 608 is located at the lower end of the cylinder 604, the drip irrigation hole 609 is located at the upper end of the cleaning plate 608, and the cleaning brush 607 Located at the lower end of the cleaning plate 608, a welding block is arr...

Embodiment 2

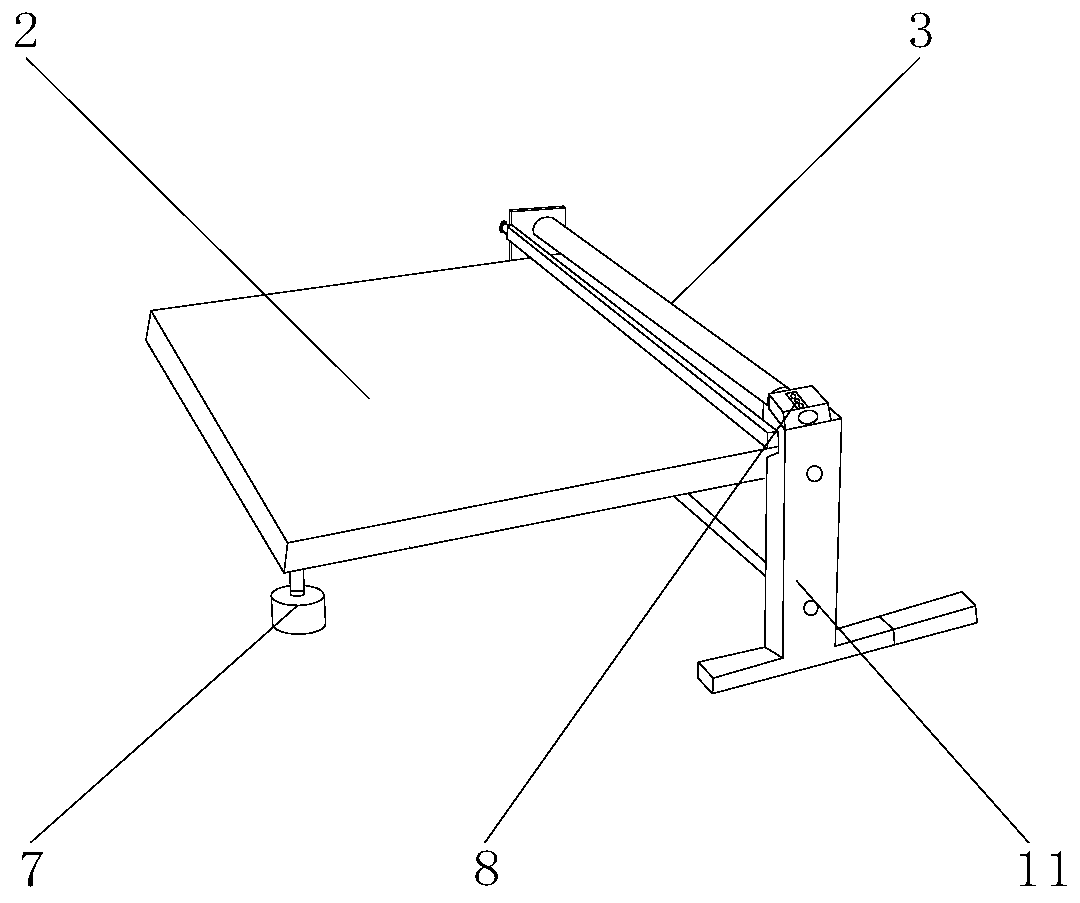

[0030] Embodiment two: if Figure 5 As shown, the detachable lubrication protection mechanism 8 includes a corner code 801, a shaft groove 802, a protective cover 803, a cover plate 804, a lubricating oil drip irrigation tank 805, and an observation window 806. The shaft groove 802 is located inside the protective cover 803, and the corner code 801 is located on one side of the protective cover 803, the lubricating oil drip irrigation tank 805 is located at the upper end of the protective cover 803, the cover plate 804 is located at the upper end of the lubricating oil drip irrigation tank 805, the observation window 806 is located at the front end of the protective cover 803, the corner code 801 and the protective cover 803 Screws are arranged between them, and one side of the corner code 801 is fixedly connected with one side of the protective cover 803 by screws, and a slot is provided between the protective cover 803 and the observation window 806, and the outer surface of ...

Embodiment 3

[0031] Embodiment three: as Figure 6 , 7 As shown, the self-cleaning discharge roller support mechanism 9 includes an anti-corrosion layer 901, a reinforcement layer 902, a rust removal layer 903, a secondary shaft 904, a self-cleaning layer 905, and a discharge roller 906. The secondary shaft 904 is located on the discharge roller 906 The self-cleaning layer 905 is located on the outer surface of the discharge roller 906, the anti-corrosion layer 901, the strengthening layer 902, and the rust removal layer 903 are all located inside the discharge roller 906, and the reinforcement layer 902 is located on the outer surface of the anti-corrosion layer 901 , the derusting layer 903 is located on the outer surface of the reinforcing layer 902, and a strong glue is arranged between the self-cleaning layer 905 and the discharge roller 906, and the outer surface of the discharge roller 906 passes through the superglue and the inner surface of the self-cleaning layer 905. The surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com