Welding strain measurement system and method based on three-dimensional digital image correlation method

An image correlation and welding strain technology, applied in measurement devices, image analysis, image data processing, etc., can solve the problems of increased image brightness, increased error of three-dimensional strain field results, speckle slip, etc., and achieves a simple and compact system structure. , to avoid damage caused by welding, reduce the effect of arc interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

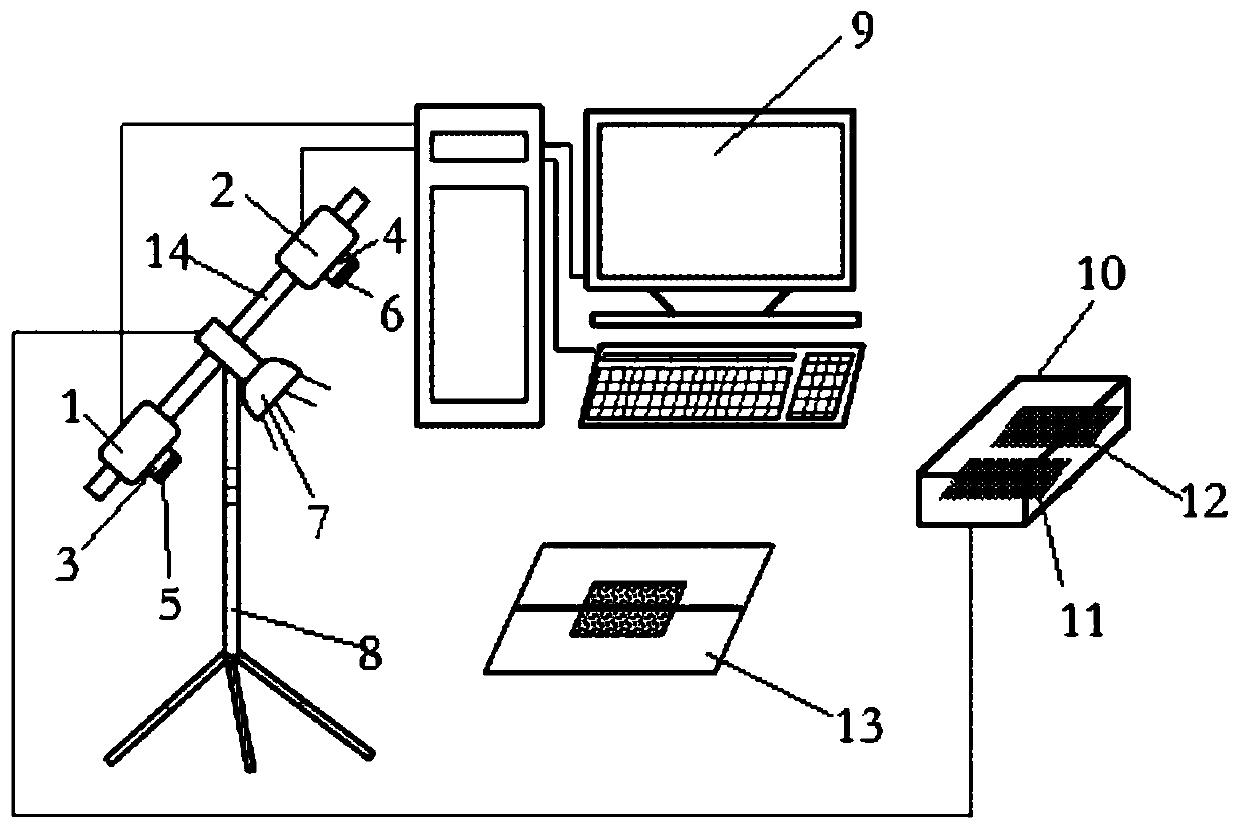

[0046] Such as figure 1 As shown, the application proposes a welding strain measurement system based on a three-dimensional digital image correlation method, including a camera, an optical lens, an image acquisition card, a filter of a specific wavelength, a light reduction film, a laser light source 7, a laser driver 11, and a synchronous trigger Board 12, calibration board, support platform 14, power supply and computer 9 for digital image acquisition and image analysis and processing. The supporting platform 14 is arranged on the support 8, and in this embodiment, the support 8 is specifically a tripod.

[0047]The camera is an industrial camera, including a first camera 1 and a second camera 2, which are installed at both ends of the supporting platform 14 in translation. The threaded hole of the camera is located below it, and it is fixed on the supporting platform 14 above the tripod by threaded holes and screws, and a guide rail is installed on the supporting platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com